Steel having excellent machinability for mechanical structure

A technology of mechanical structure and quality, applied in the field of steel for mechanical structure, to achieve the effect of excellent machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

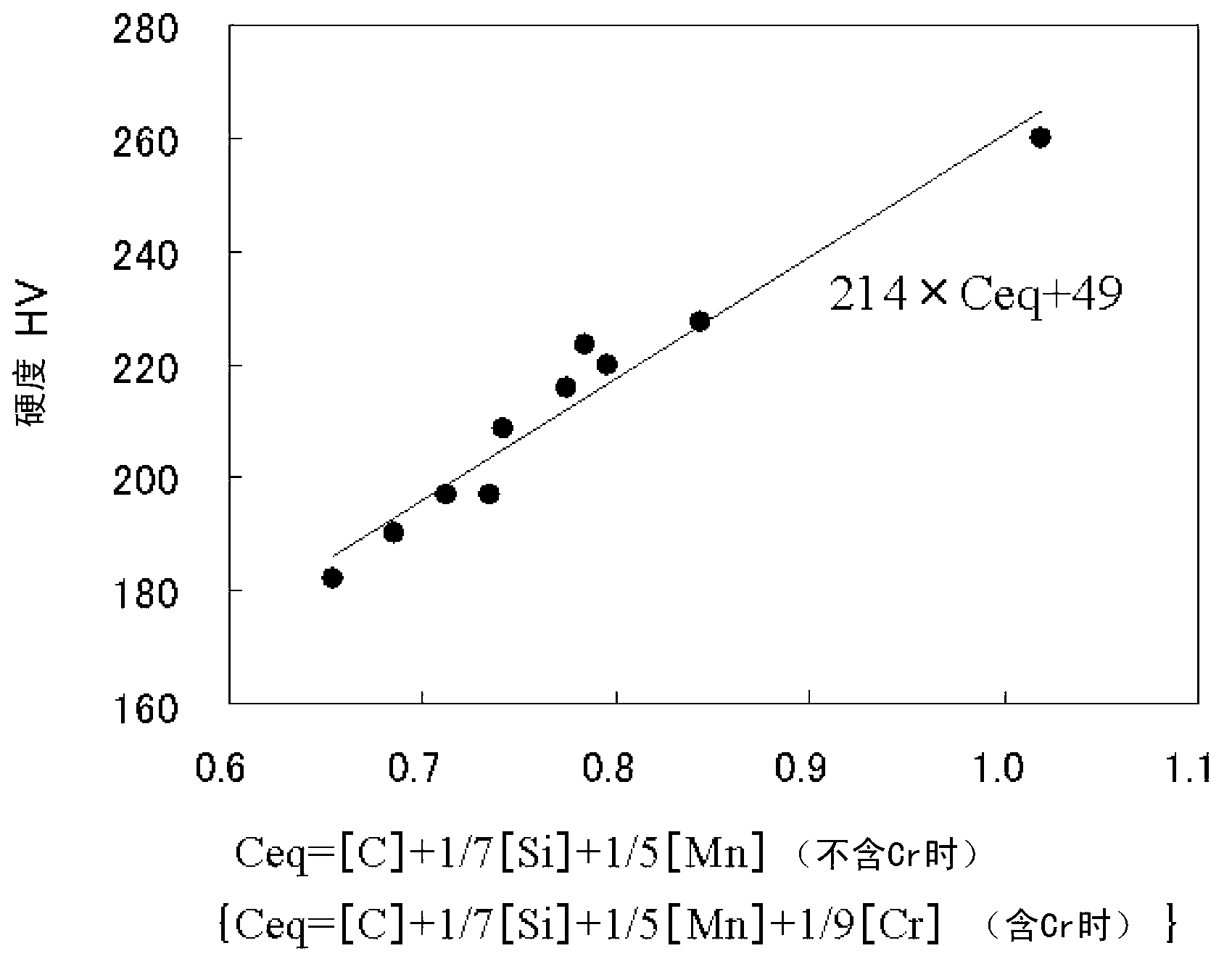

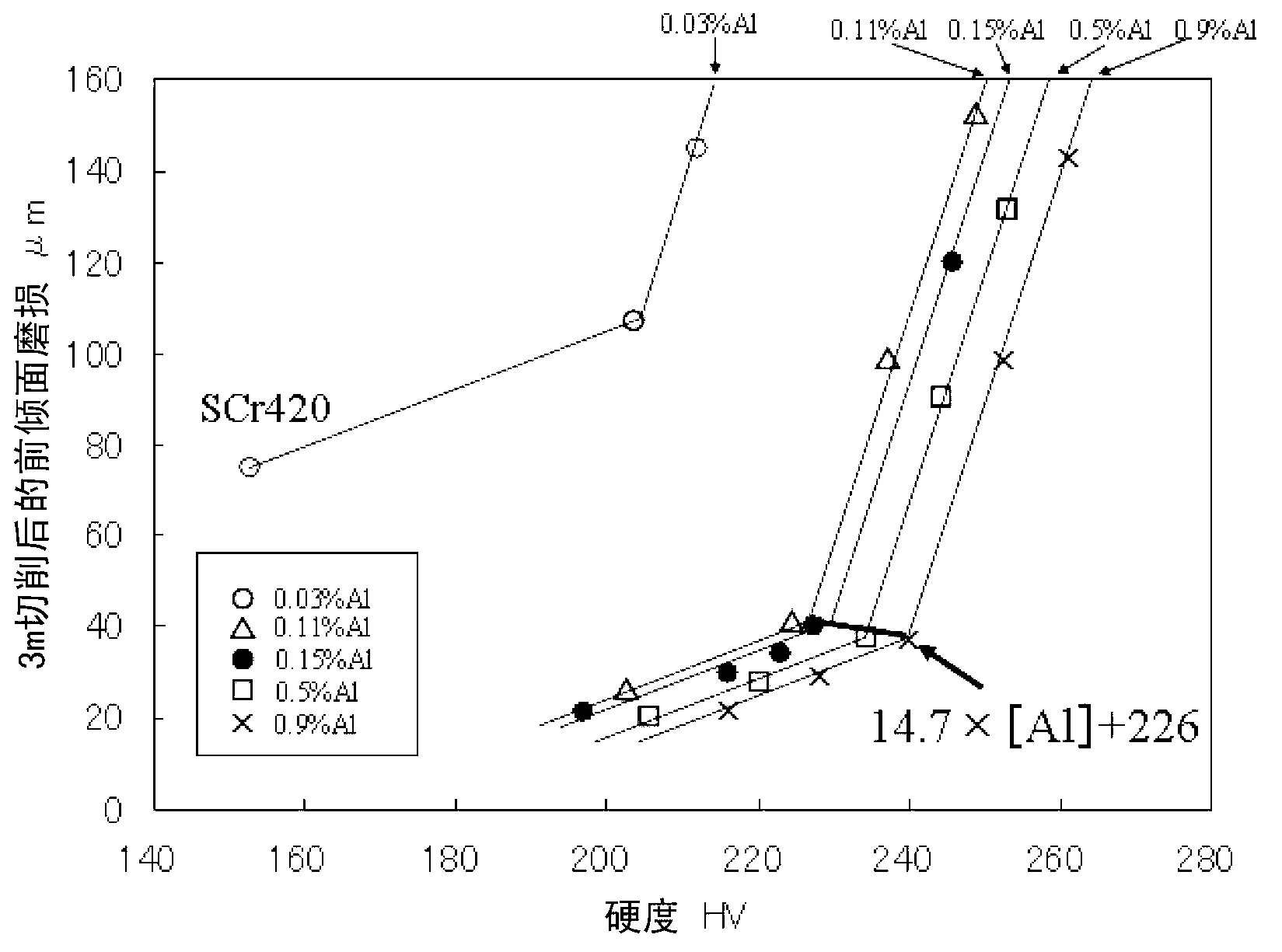

[0180] Steels having the compositions shown in Tables 2 and 3 were melted and rolled into 65Φ steel bars. In Tables 4 to 6, steel numbers 1 to 105 show the value of formula (1), the value of formula (2), the value of formula (3), the value of formula (4), and the value of formula (5). When the steel contains Cr, the value of formula (6), the value of formula (7), the value of formula (8), and the value of formula (9) are shown. Steels with numbers 1 to 94 are invention examples, and steels with numbers 95 to 105 are comparative examples.

[0181] After holding the above-mentioned bar steel at 900°C for 1 hour, it was air-cooled, and the test piece was cut out. Before quenching, the hardness (Hv), tool wear (μm) and proeutectoid ferrite fraction were measured. Rate(%). The results are shown in Tables 4-6. In addition, after quenching, the 300°C tempering hardness Hv and the roller pitting fatigue strength (fatigue limit, MPa) of the hardened layer were measured. The results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com