Free-cutting anticorrosive brass alloy and its prepn process

A brass alloy, easy-cutting technology, applied in the fields of electronic and telecommunication connectors, switch connectors, valve parts, civil water supply system pipe castings, lead-free low-boron bismuth brass alloys, can solve the problem of high market prices, and achieve Effect of improving dezincification corrosion resistance, low manufacturing cost, and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

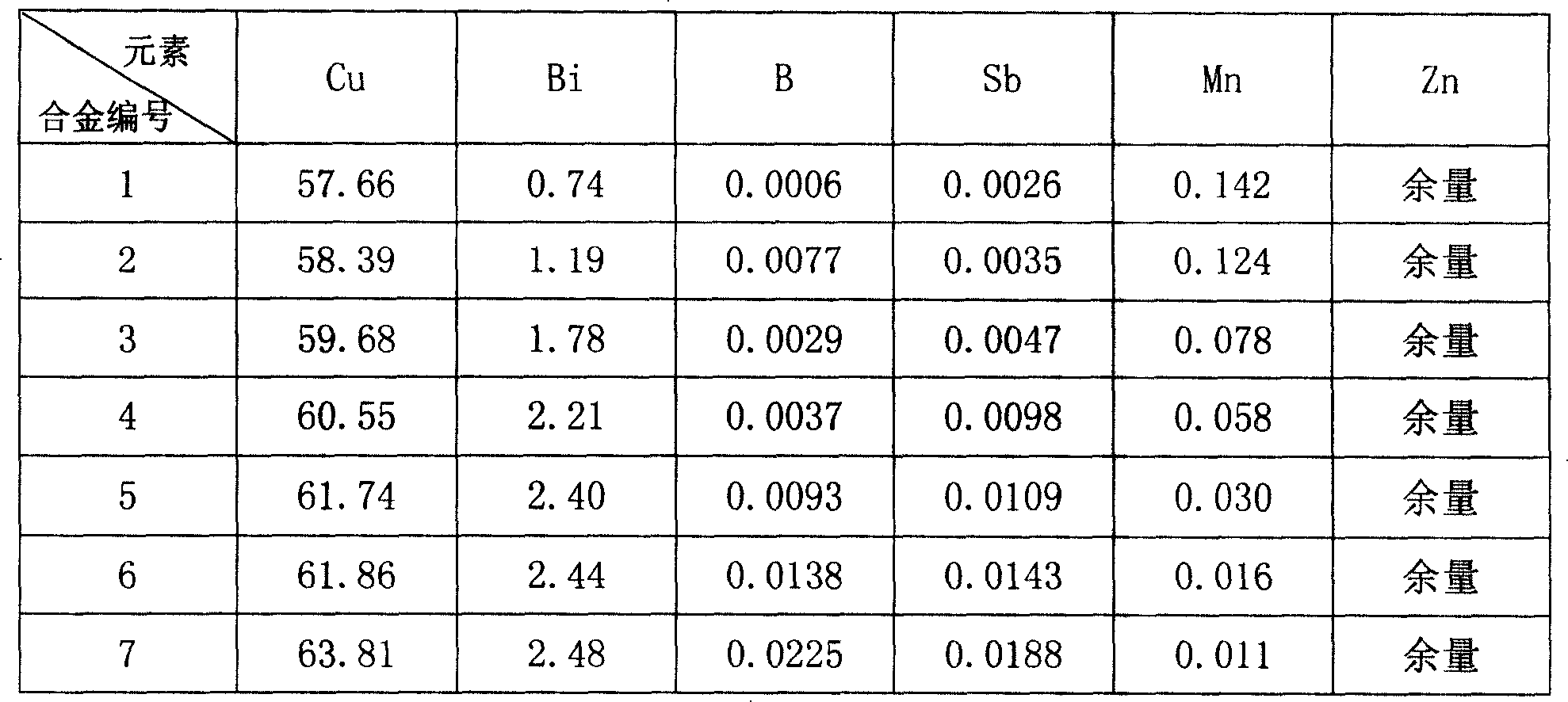

[0021] Below in conjunction with specific embodiment the invention is described in further detail:

[0022] The production technological process of brass alloy in the embodiment of the present invention is as follows:

[0023] Raw material preparation and batching—alloying smelting—continuous ingot casting—ingot heating—extrusion—stretching—heat treatment—pickling—stretching—straightening and polishing—stress relief annealing— - Inspection of finished product packaging.

[0024] Specifically, it can be expressed as follows: low-boron bismuth brass alloy is smelted by alloying treatment and covering protection method, so that metal bismuth and boron are rapidly solid-solved into intermetallic compounds in brass melt, and continuously cast into brass at 1020 °C Ingot casting, high extrusion ratio extrusion at 680-770°C, intermediate heat treatment annealing at 430-700°C according to cold working conditions, and stress-relief annealing at a temperature lower than 400°C.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com