Power-matallurgy valve seat inserts

A powder and metal powder technology, applied in the field of metal powder mixture, can solve the problem of expensive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

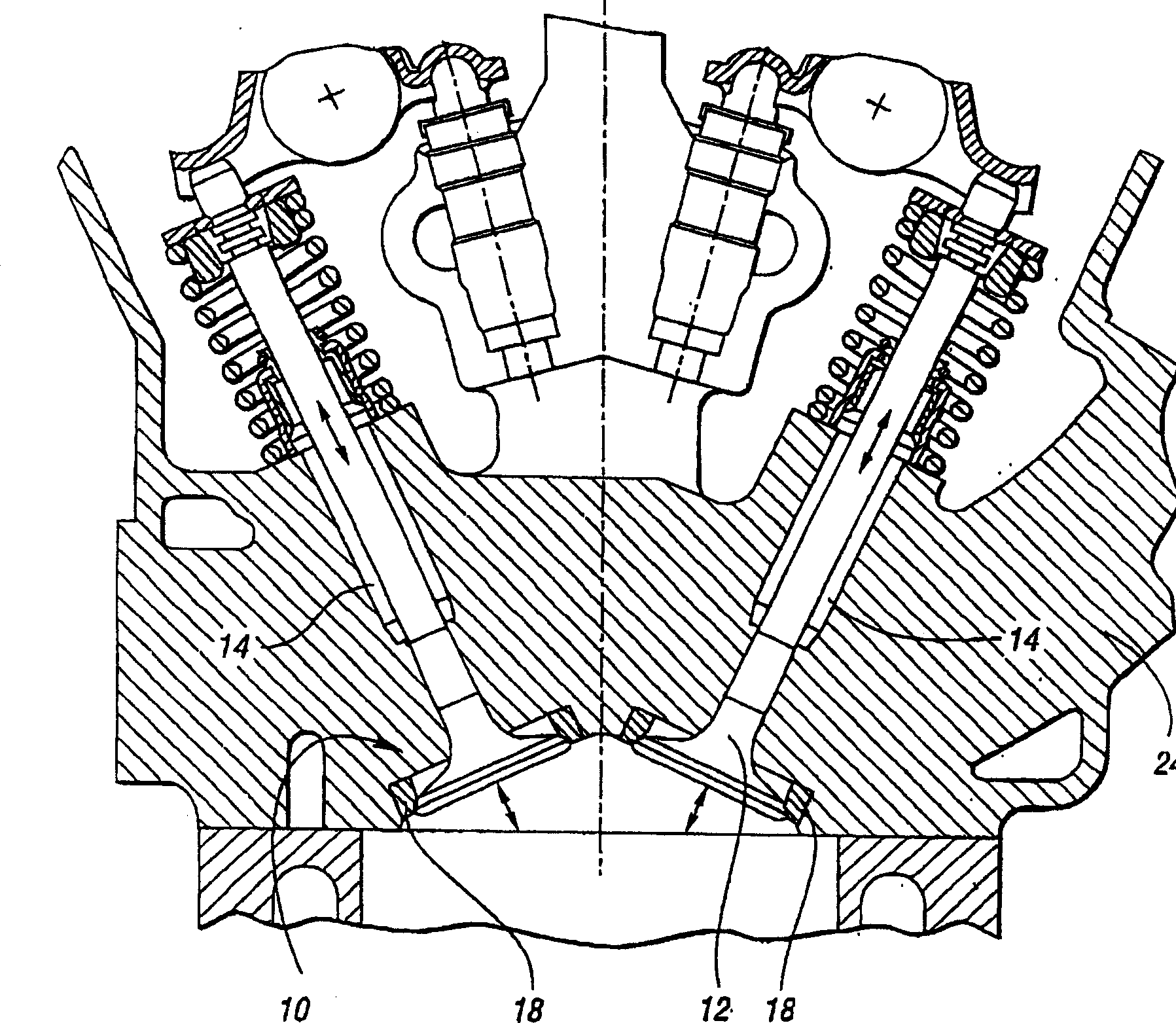

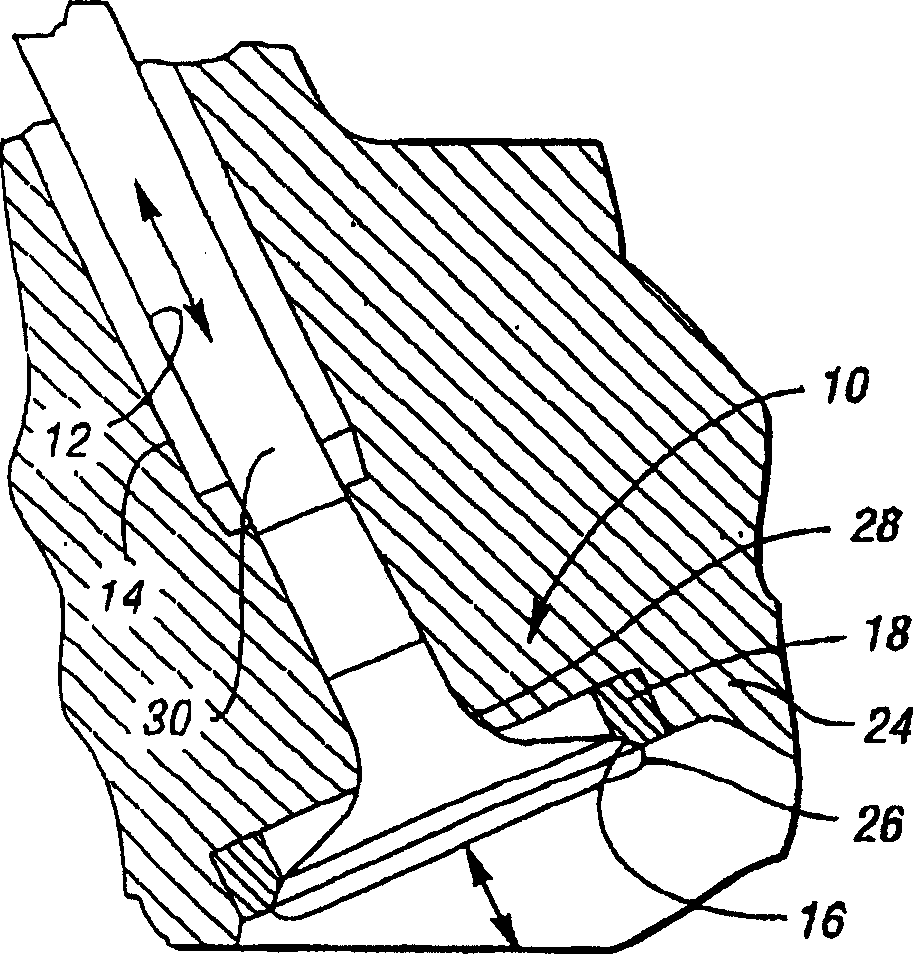

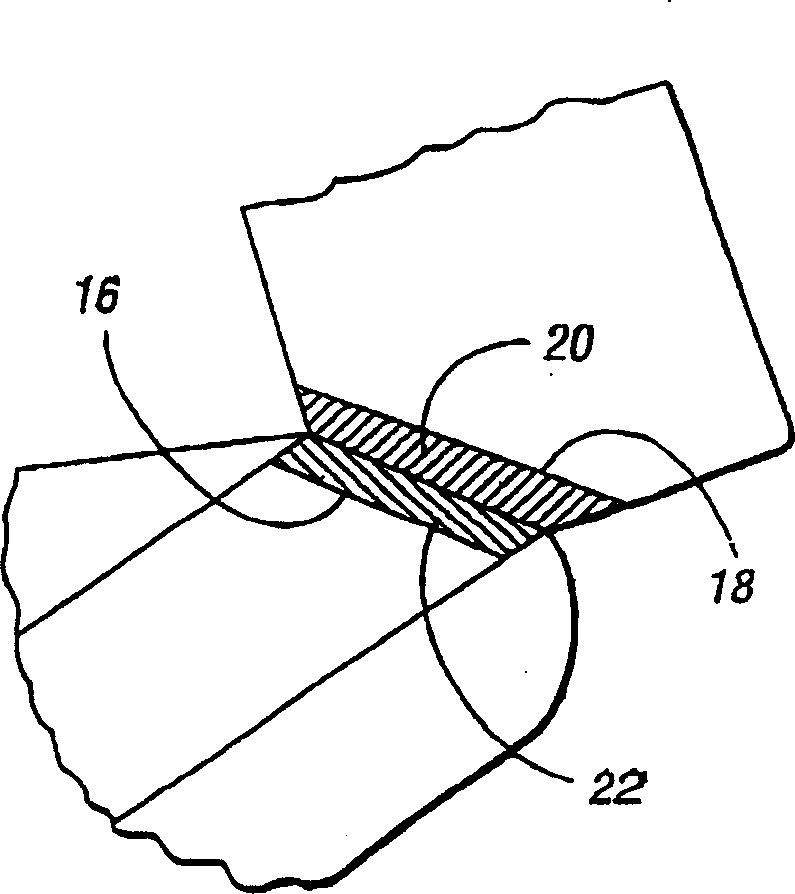

Image

Examples

Embodiment 1

[0115] Powders having the following composition were mixed in an overhead cone mixer for 30 minutes. The composition of the mixture is: 20% valve steel powder (such as 23-8N or 21-4 N or 21-2 N grades, commercially available from OMG Americas), 5% nickel commercially available from Inco, 2% Copper, commercially available from OMG Americas, 10% iron alloy powder (such as iron molybdenum powder commercially available from ShieldAlloy), 10% tool steel powder (such as M series tool steel powder commercially available from Powdrex), 3% Solid lubricant (such as molybdenum disulfide commercially available from Hohman Plating), 1% graphite commercially available from Southwestern Graphite, 1% solid lubricant (such as powdered hydrated magnesium silicate or talc ), 1% of Acrawax C, a powdered fugitive lubricant commercially available from Baychem, and the balance being low alloy steel powder containing 0.85-1.5% molybdenum, commercially available from Hoeganaes. The weight percent of ...

Embodiment 2

[0127] Powders having the following composition were mixed in an overhead cone mixer for 30 minutes. The mixture consisted of: 20% valve steel powder (such as 23-8N or 21-4N or 21-2N grades, commercially available from OMG Americas), 5% nickel commercially available from Inco, 2% commercially available from OMG Copper commercially available from Americas, 10% ferrous alloy powder (such as iron molybdenum powder commercially available from ShieldAlloy), 10% tool steel powder (such as M series tool steel powder commercially available from Powdrex), 3% solid lubricant additive (such as molybdenum disulfide commercially available from Hohman Plating), 1% graphite commercially available from Southwestern Graphite, 1% solid lubricant (powdered hydrated magnesium silicate or talc commercially available from Millwhite), balance It is a low alloy steel powder containing 1.5% molybdenum, commercially available from Hoeganaes.

[0128] The weight percent of mixture component in kilogram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com