Beam-column anti-seismic connecting joint and connecting method thereof

A technology for connecting nodes and beams and columns, applied in the direction of earthquake resistance, building components, building types, etc., can solve the problems of reduced friction effect, limited friction force, poor shock absorption effect, etc., and achieve the effect of facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

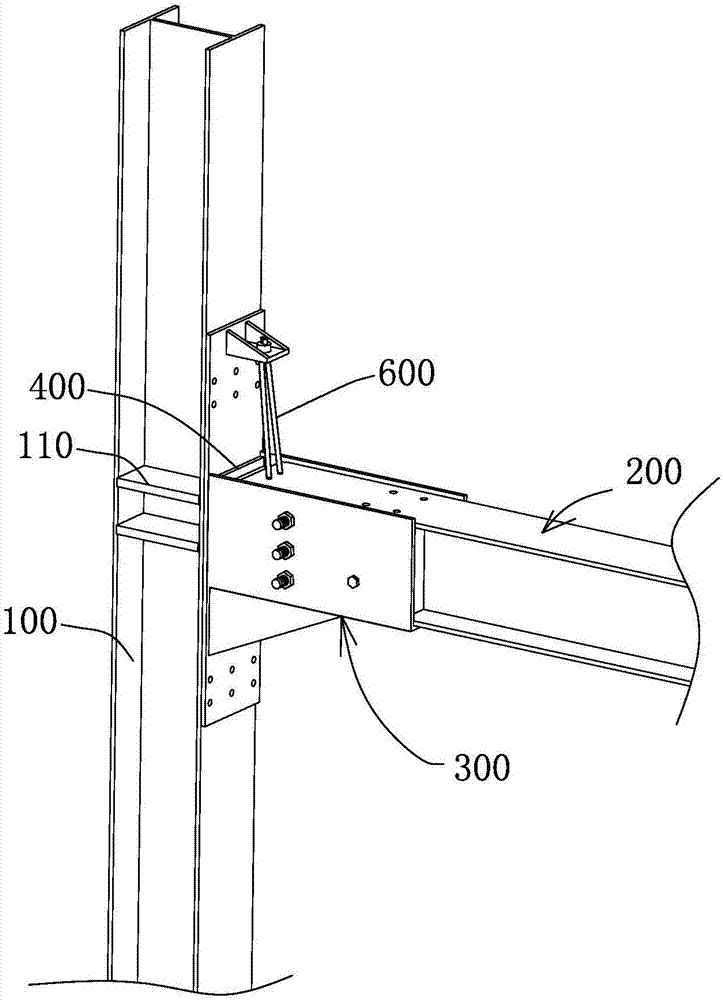

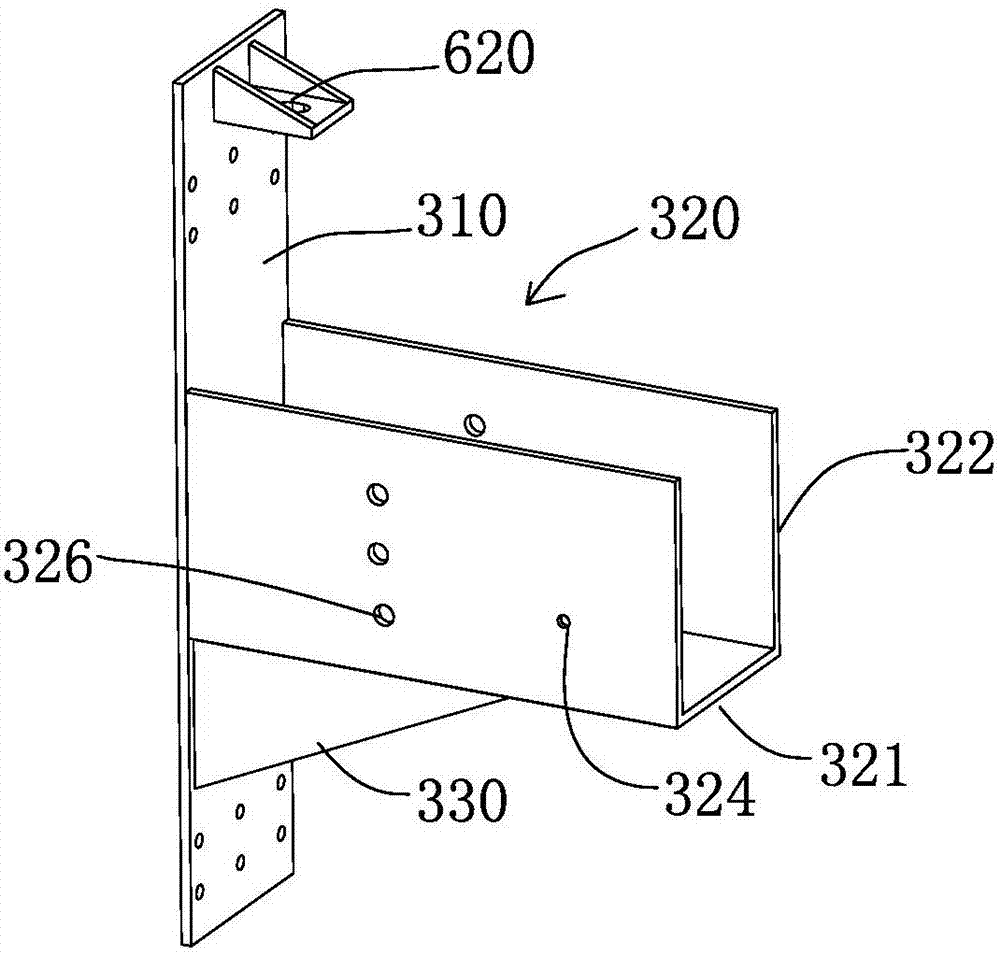

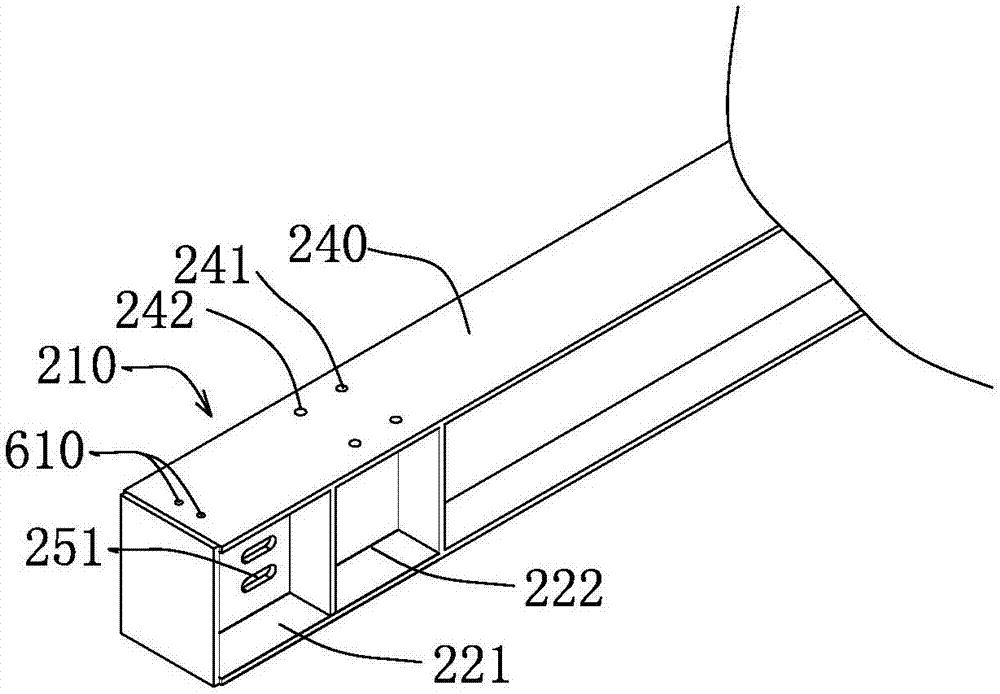

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0042] Assembled steel structure beam-column connection node is suitable for the connection of steel beams and steel columns. The steel column mentioned in the present invention refers to a steel column that is usually in a vertical state or close to a vertical state. It is mainly based on the ground, and the inclined ones are also slightly inclined, usually with an angle of no more than 15 degrees. The steel girder here is usually in a horizontal state in steel structure buildings.

[0043] The steel beams and steel columns here only include I-shaped steel materials commonly used in steel structures, and other structures, such as square steel and channel steel, are not within the scope of the present invention.

[0044] Based on the research of I-steel beams and steel columns, I-steel has good torsion resistance and bending resistance, and saves steel, so it is wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com