Front seat cross beam assembly

A front seat and crossbeam assembly technology, which is applied to vehicle seats, special positions of the vehicle, and vehicle components, can solve problems such as weak side bearing force and unfavorable occupant safety, so as to increase the force-bearing area and ensure Safe and innovative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

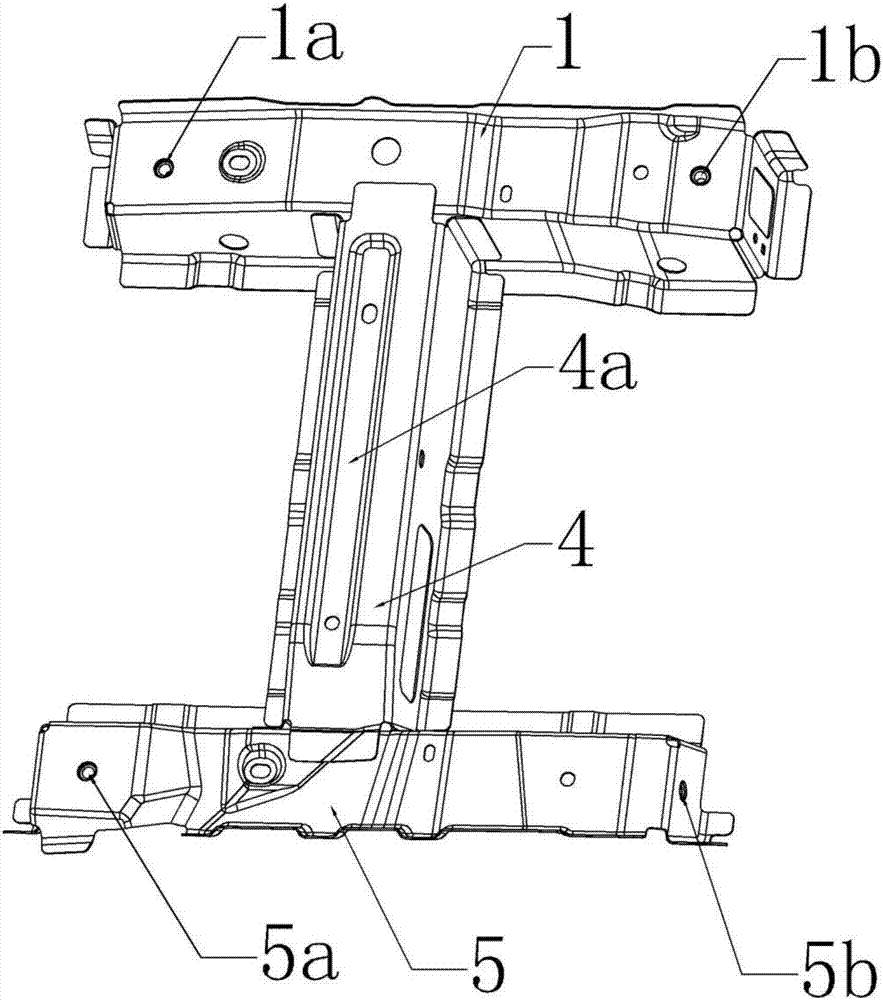

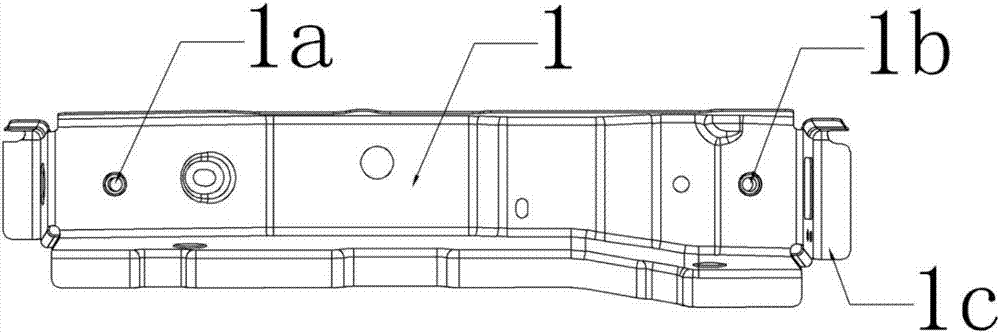

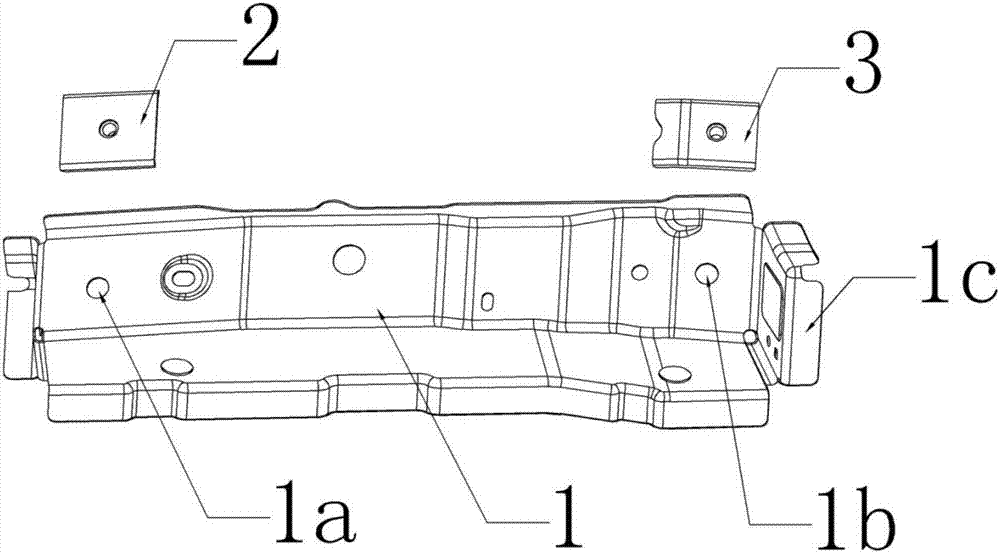

[0016] like Figure 1 to Figure 5 The shown front seat beam assembly has an outer mounting bracket 1 arranged laterally, and the upper panel of the outer mounting bracket 1 is curved. The left and right ends and the lower end of the upper panel of the outer mounting bracket 1 are respectively provided with outer bracket side panels 1c, and the edges of the outer bracket side panels 1c are bent at right angles. The two ends of the upper panel of the outer mounting bracket 1 are respectively provided with a first threaded hole 1a and a second threaded hole 1b, which are respectively opposite to the first threaded hole 1a and the second threaded hole 1b. A first front mounting nut plate 2 and a first rear mounting nut plate 3 with screw holes are respectively fixedly arranged on the back side. A front row seat crossbeam 4 is arranged vertically below the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com