Prefabricated steel plate-high-ductility concrete coupling beam

A technology of high ductility concrete and steel plate, applied in the direction of building components, building types, earthquake resistance, etc., can solve the problems of brittle failure, the ductility of coupling beams and energy dissipation capacity cannot be fully exerted, and achieve the effect of strengthening the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

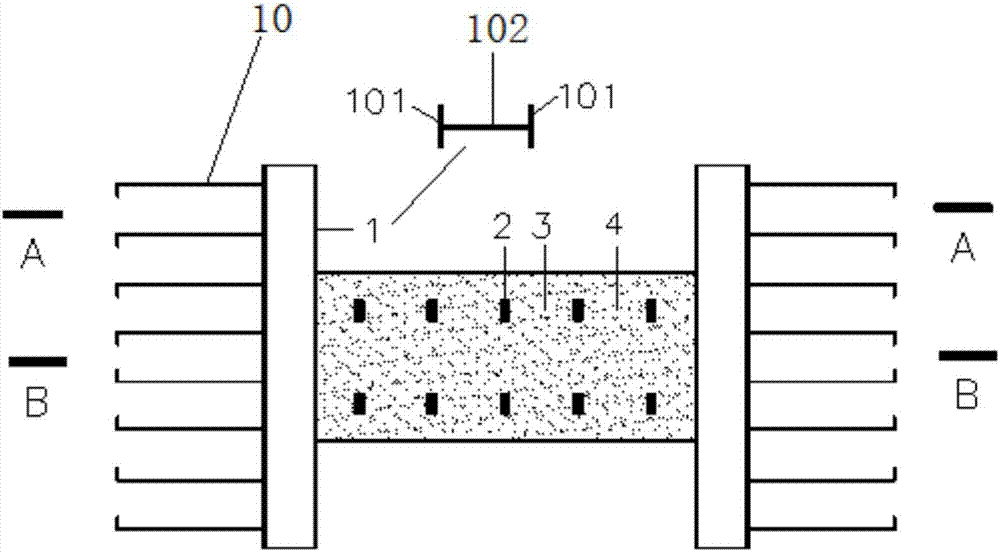

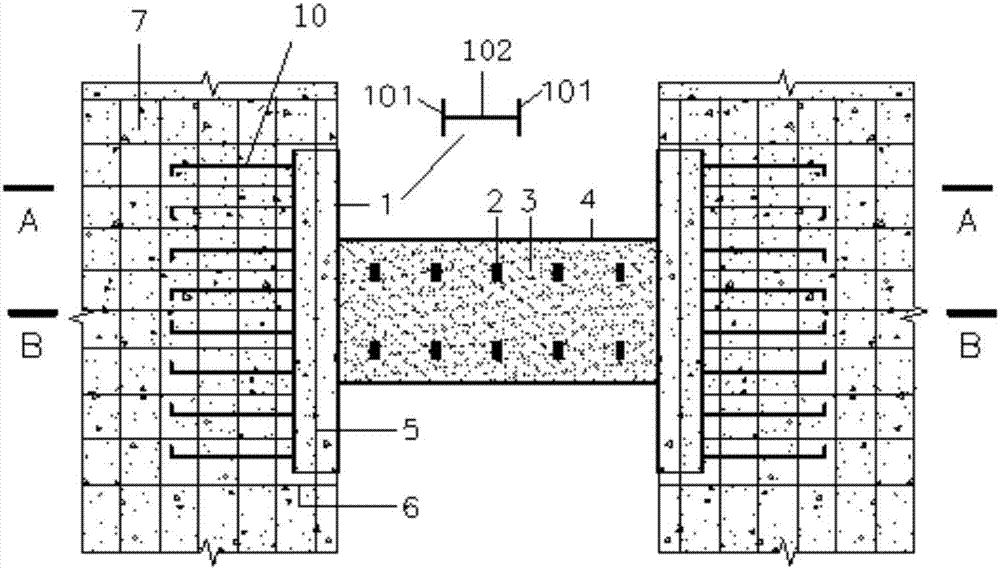

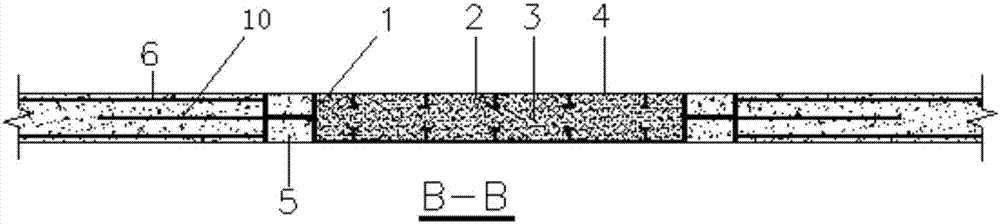

[0042] The coupling beam in this embodiment is an energy-consuming coupling beam with a span-to-height ratio of 1.5 for a high-rise residential building, with a net span of 600mm and a cross-sectional size of 400×200mm; the thickness of the outer steel plate 4 is 5mm, and the steel plate adopts Q235; T-shaped steel plate The connector 2 is made of Q235 steel, the diameter of the perforation 9 is 30mm, and the spacing is 30mm. The longitudinal spacing of the T-shaped steel plate connector 2 is 150mm and the transverse spacing is 150mm; the H-beam 1 uses the national standard H400x200a model; the diameter of the anchoring steel bar 10 is 12mm, the spacing is 150mm, the diameter of the pouring hole 8 is 150mm, and only one pouring hole is provided in this embodiment.

[0043] construction process:

[0044] 1) First, cut the required steel plate 4 according to the size of the coupling beam; pre-welded a number of T-shaped steel plate connectors 2 on the steel plates on both sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com