Lead-free solder alloy

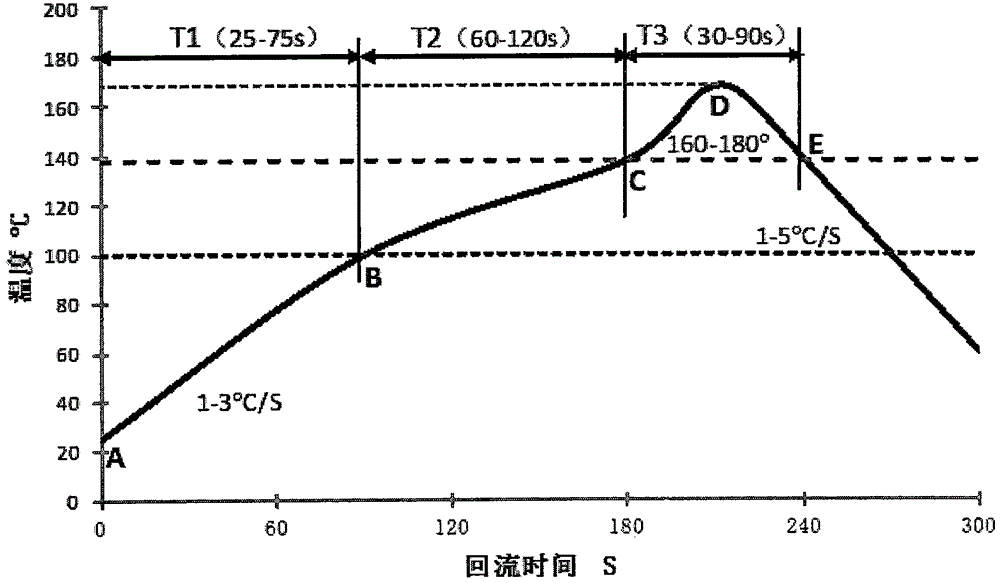

A technology of lead-free solder alloy and solder alloy, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., which can solve the adverse effects of increasing temperature performance and assembly quality, increasing energy consumption of electronic assembly, comprehensive energy To improve the resistance to mechanical shock and drop, improve the coarseness of Bi phase grains, and reduce the effect of poor welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

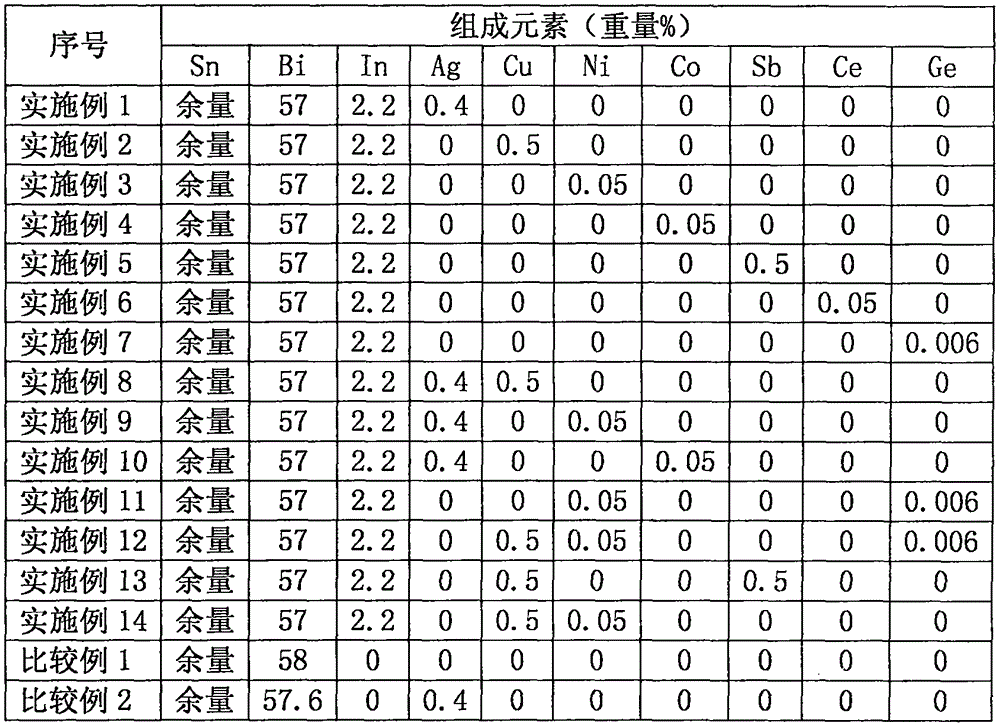

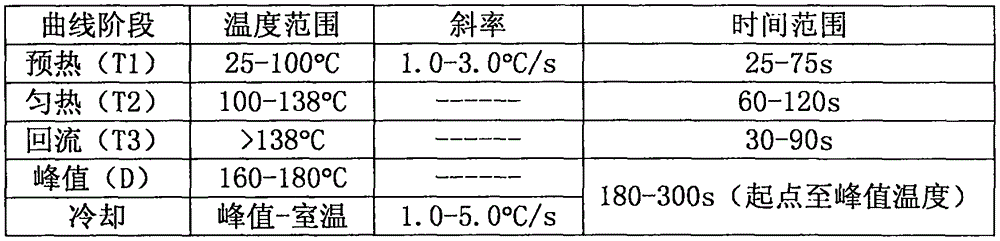

[0075] The specific examples of the present invention and the solder formulations of the comparative examples are shown in Table 1, wherein the contents of the main components Sn and Bi of the comparative examples 1 and 2 are basically the same as those of the examples so that performance comparisons can be carried out.

[0076] Table 1: Examples and Comparative Examples

[0077]

[0078] The steps of the manufacturing method of each of the above-mentioned embodiments are as follows:

[0079] (1) Melting Sn and In, microalloying elements Ag, Cu, Ni, Co, Mn, Ti, Sb and anti-oxidation elements P, Ge, Ga respectively in a vacuum induction heating furnace to form an intermediate alloy;

[0080] (2) smelting rare earth elements and Bi in a vacuum induction heating furnace to form rare earth alloys;

[0081] (3) Melt the rest of the Sn, Bi and Sn-In master alloys in a vacuum induction heating furnace at a melting temperature of 300-350°C, stir thoroughly for 60-90 minutes, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com