Device and method for cleaning spray head

A technology for cleaning nozzles and nozzles, which is applied in printing and other directions, and can solve problems such as plugging nozzles, clogging nozzles, ink or impurities clogging nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

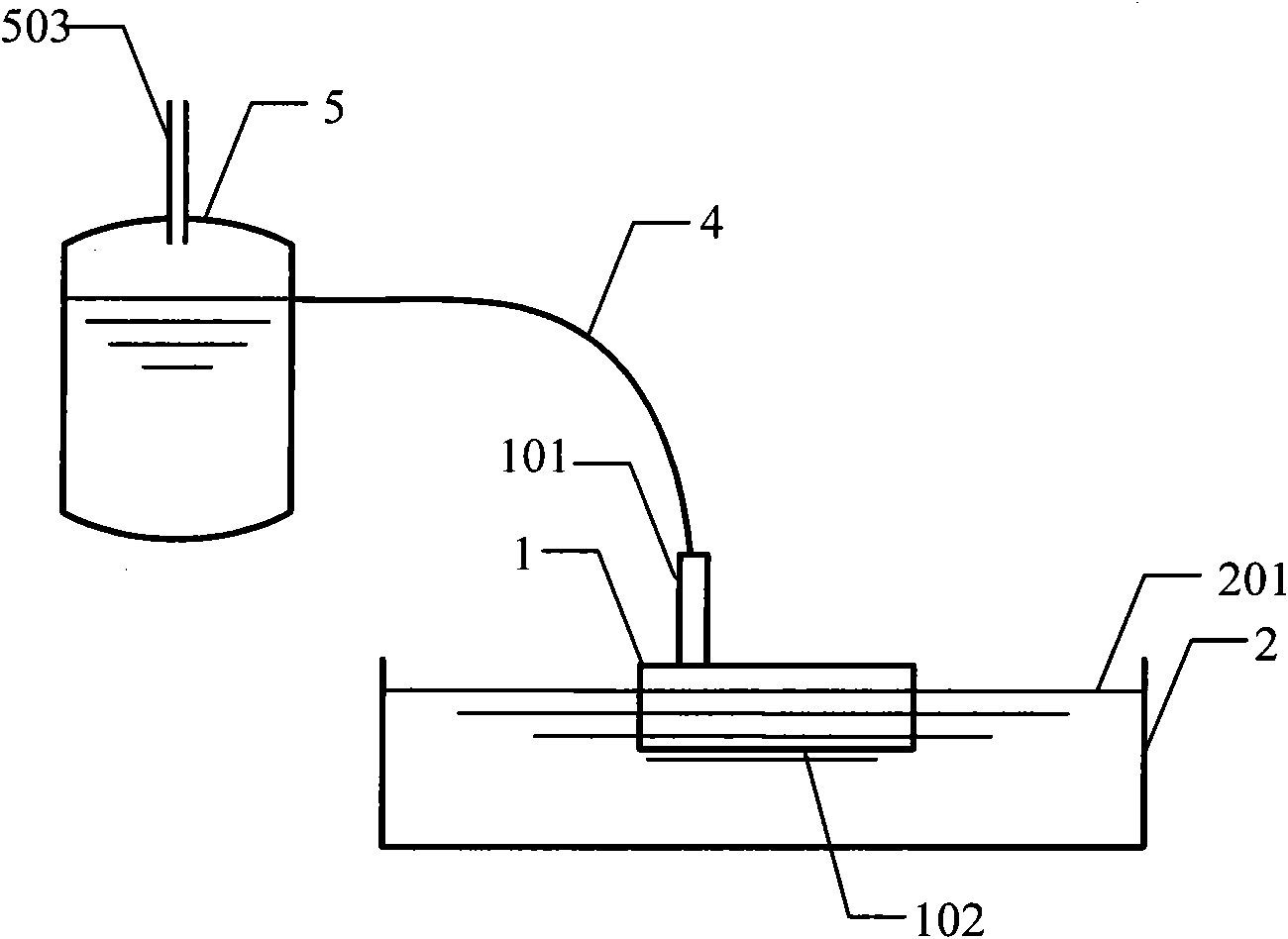

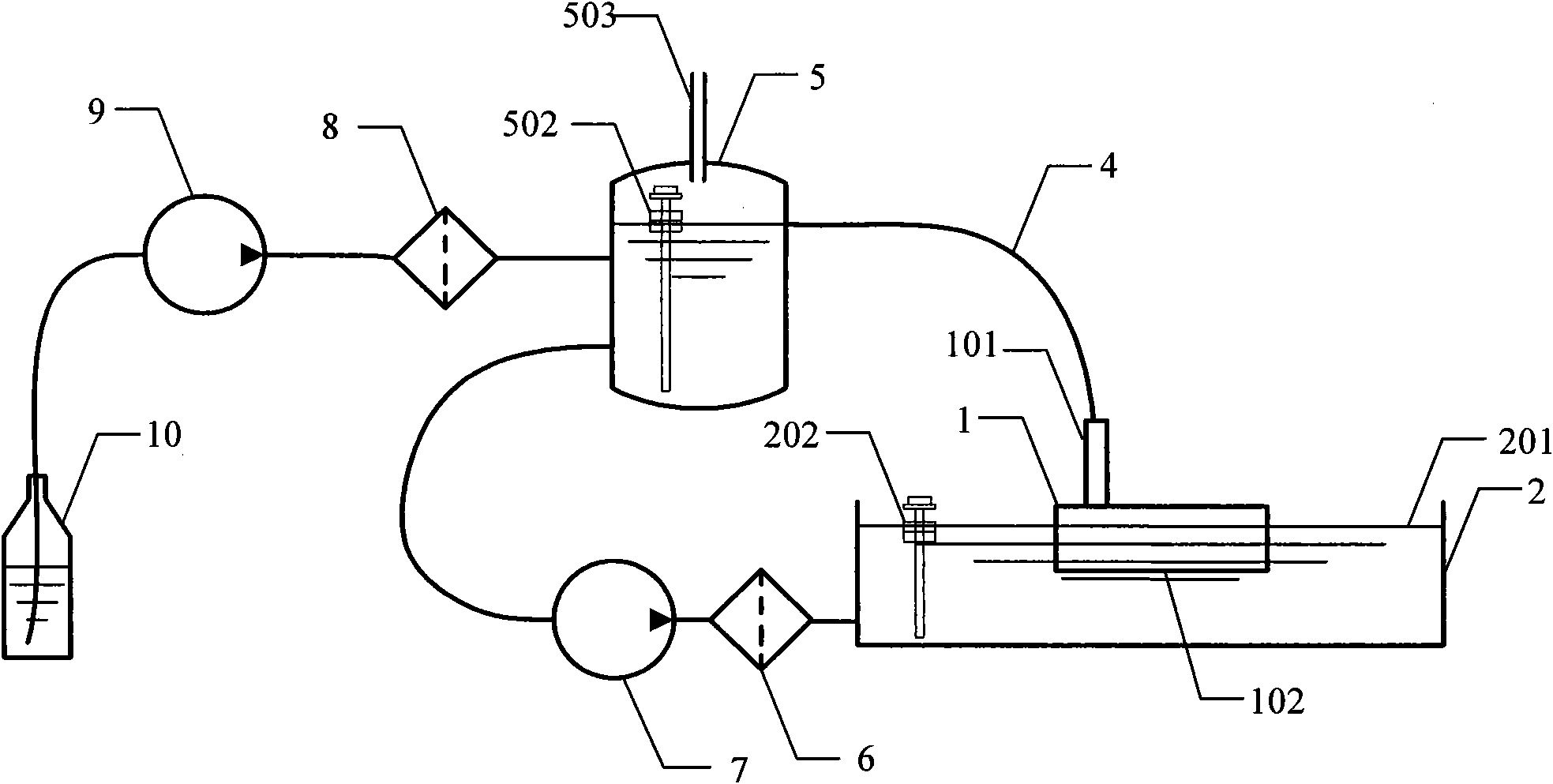

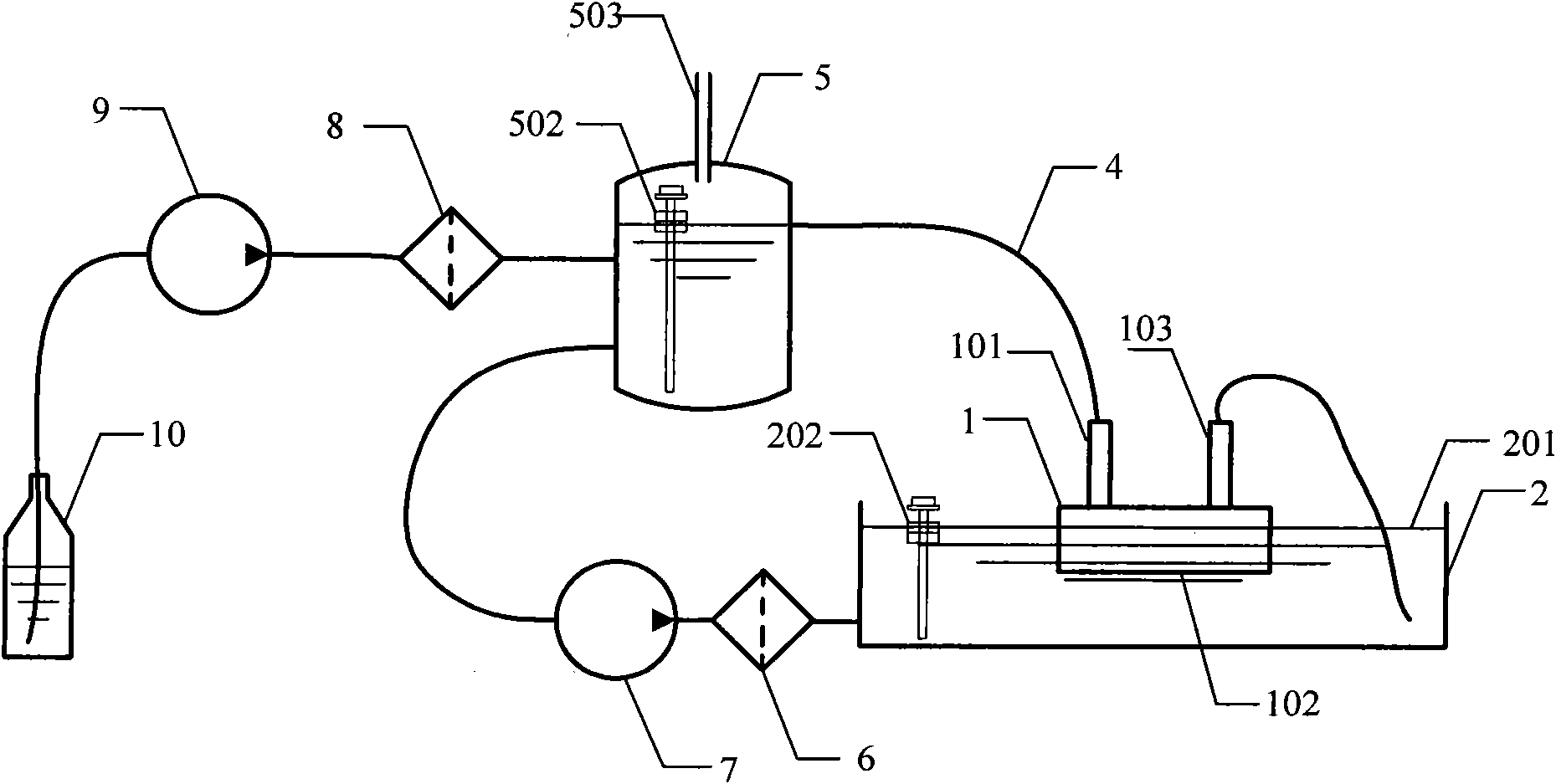

[0014] The embodiment of the present invention provides a device and method for cleaning the nozzle. The negative pressure generating device makes the cleaning liquid reversely flow inside the nozzle, thereby preventing the solidified ink and other impurities from clogging the nozzle, and achieving the purpose of more thorough cleaning of the nozzle.

[0015] An embodiment of the present invention provides a device for cleaning the nozzle, including: a cleaning tank and a negative pressure device, the cleaning tank is equipped with cleaning liquid for submerging the nozzle of the nozzle, wherein,

[0016] The ink port of the nozzle is in communication with the negative pressure device, wherein, under the negative pressure of the negative pressure device, the cleaning liquid is sucked from the nozzle of the nozzle and flows out from the ink port to the negative pressure device.

[0017] Preferably, the negative pressure device includes a negative pressure generating device and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com