Testing device for measuring shearing strength parameter changes in solidifying process of soft clay

A technology of shear strength and parameter changes, applied in measuring devices, using stable shear force to test material strength, soil material testing, etc. and other problems, to achieve the effect of rich experimental types and universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

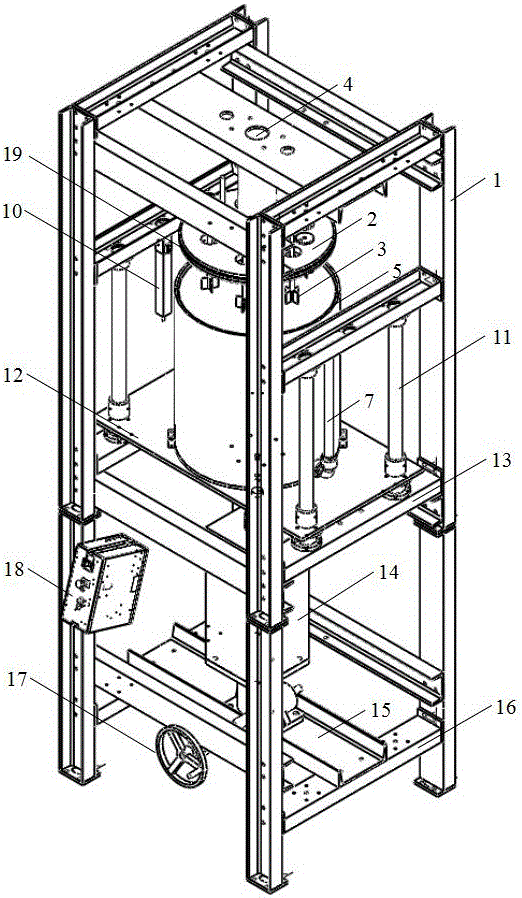

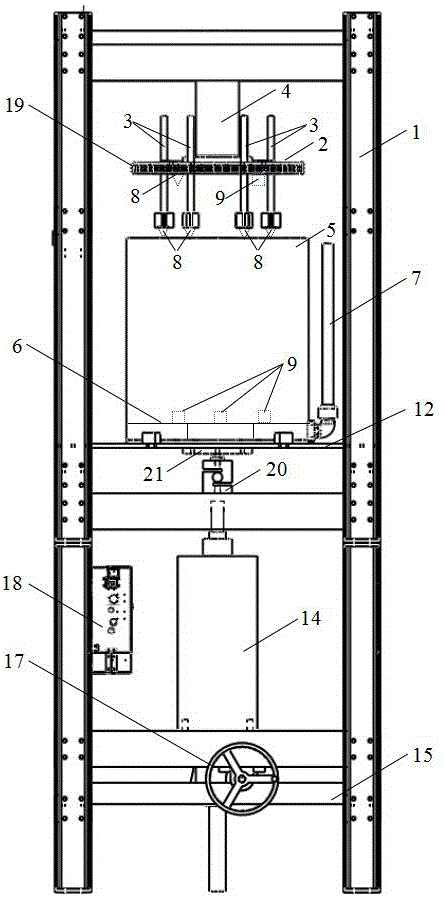

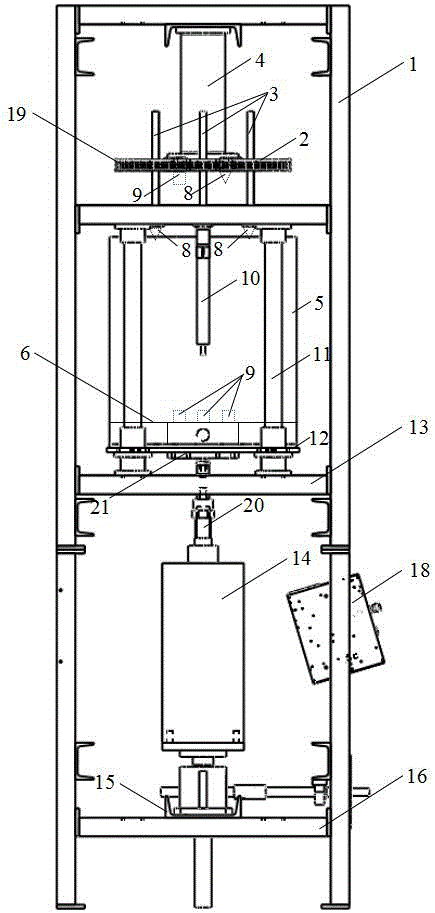

[0032] The invention relates to a test device for measuring the change of shear strength parameters during the consolidation process of soft clay, comprising a frame 1, a loading plate 2, six miniature cross-plate shear instruments 3 with hole pressure testing functions, a torque meter, A sample chamber 5 for placing samples, a measuring unit and a lifting mechanism;

[0033] The bottom of the sample chamber 5 is provided with a drainage device, and the drainage device includes a drain plate 6 and a drain pipe 7; the sample chamber 5 is a cylinder, and the drain plate 6 is a circular plate whose diameter is equal to the inner diameter of the sample chamber 5;

[0034] The drain plate 6 is arranged at the bottom of the sample chamber 5, and the drain plate 6 and the bottom of the sample chamber 5 form a drain chamber, and one end of the drain pipe 7 is rotated to communicate with the drain chamber, and the other end of the drain pipe 7 can be adjusted to be in line with the samp...

Embodiment 2

[0057] like figure 1 As shown, a test device for measuring the change of shear strength parameters during the consolidation process of soft clay, including frame 1, loading plate 2, six miniature cross-plate shear instruments 3 with pore pressure test function, torsion meter, for The sample chamber 5 for placing the sample, the measuring unit and the lifting mechanism;

[0058] The bottom of the sample chamber 5 is provided with a drainage device, and the drain device includes a drain board 6 and a drain pipe 7; One end of the pipe 7 is rotated to communicate with the drain cavity, and the other end of the drain pipe 7 can be adjusted to be at the same height as the top wall of the sample chamber 5, and the drain pipe 7 is located outside the sample chamber 5; the sample chamber 5 is a cylinder, and the drain plate 6 is a circular plate whose diameter is equal to the inner diameter of the sample chamber 5;

[0059] The drain board 6 is provided with a plurality of evenly dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com