Method for extracting shale oil and gas from oil shale in situ

A technology for shale oil, gas and oil shale, applied in the field of oil shale mining, can solve the problems of restricting large-scale promotion, high acid waste water, high polluting gas, etc., to reduce costs and risks, reduce construction difficulty and expenses, increase The effect of a large reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

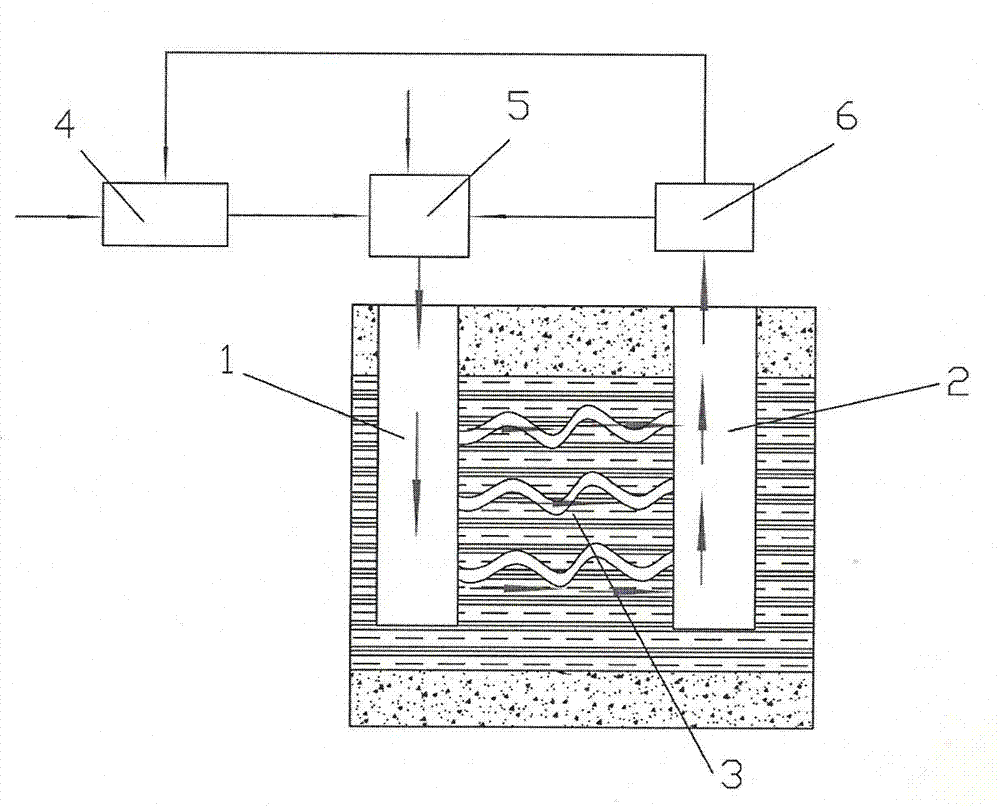

[0046] The buried depth of oil shale in a certain place is 380m-390m, the cover layer is 5m thick, the weakly weathered layer is 5-7m, the average oil content is 6%, the water content is 5%, and the fixed carbon is 15%. The roof and floor are both dense shale. The implementation steps are as follows:

[0047] (1) Drilling and completion

[0048] a. According to the distribution and direction of the oil shale layer, the distance between the heat injection well and the production well is selected to be 15m;

[0049] b. Drill a heat injection well 1 on the ground to 393m underground, and pass through the oil shale layer. The heat injection well 1 adopts a well structure with at least three openings, one opening to 10m below the floor of the overlying soft layer, and the second opening to the oil shale layer 378m, three to 393m;

[0050] c. Establish a fracturing chamber in the heat injection well 1, take out the drilling casing, and squeeze the high-pressure, large-displacemen...

Embodiment 2

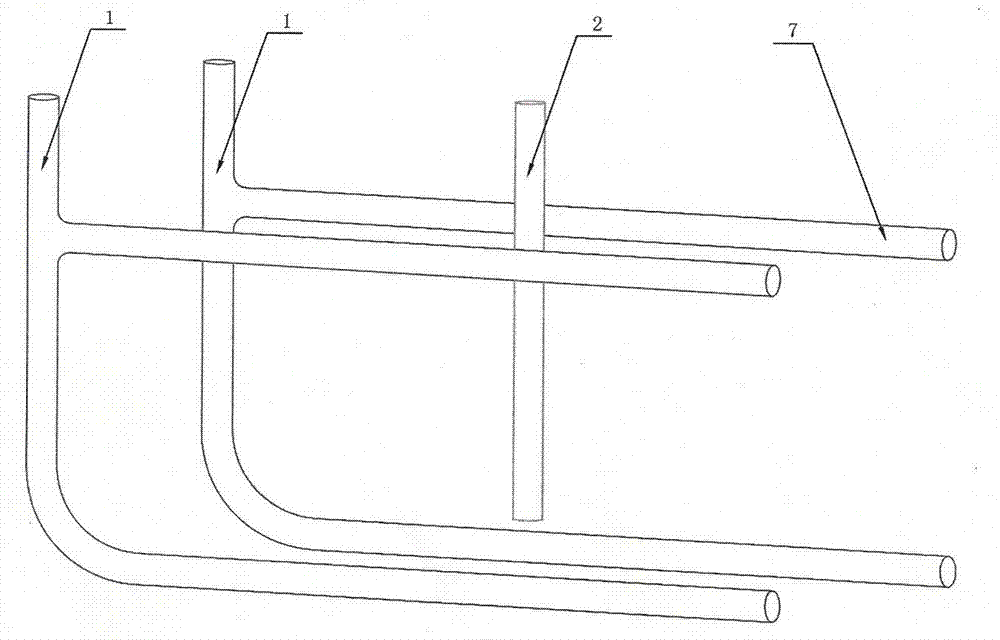

[0071] figure 2 Be embodiment 2, be the directional horizontal well form; The concrete steps of the present embodiment are as follows:

[0072] a. According to the distribution and trend of the oil shale layer, select the specific location of the heat injection well and the production well, arrange two heat injection wells 1 and one production well 2 in the delineated working area, and place each heat injection well 1 in the oil shale layer Two horizontal wells 7 are arranged in the vertical direction, and the distance between adjacent heat injection wells 1 is 25m;

[0073] b. Drill the thermal injection well 1 on the ground to the bottom plate of the oil shale layer, and continue to drill two horizontal wells 7 in two directions parallel to and close to the top plate of the oil shale layer and the bottom plate of the oil shale layer after passing through two certain turning radii;

[0074] c. Establish a fracturing chamber in a horizontal well connected to the heat injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com