Crystalline silicon preparation method and crystalline silicon

A technology of crystalline silicon and polycrystalline silicon, which is applied in the preparation of crystalline silicon and in the field of crystalline silicon, can solve the problems of low resistivity areas, low yield of crystalline silicon, non-concentrated resistivity distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

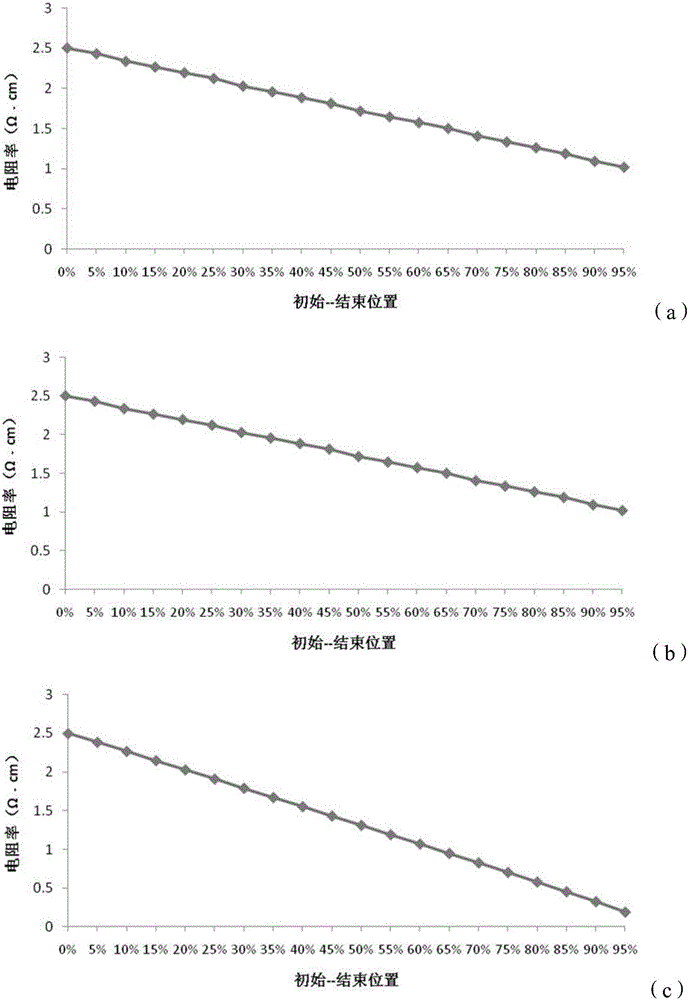

Embodiment 1

[0075] A method for preparing gallium-doped monocrystalline silicon, comprising the following steps:

[0076] 1. Feeding: mix 120kg of polysilicon material and 4.02g of metal gallium (in each cubic centimeter of silicon material, the atomic volume concentration of gallium is 6.9E+17atoms / cm 3 ) into the quartz crucible of the single crystal furnace, the model of the crucible is a 24-inch quartz crucible, so that the target resistivity of the Czochralski silicon single crystal head is 2.5Ω cm; the single crystal furnace is also provided with a continuous A feeding device, putting molten second polysilicon material into the continuous feeding device;

[0077] 2. Under the protection of argon or nitrogen, heat the temperature to 1425°C-1600°C to melt the polysilicon material and metal gallium in the quartz crucible, so that the gallium element is melted into the polysilicon solution to form a silicon melt;

[0078] 3. Place a single crystal seed crystal on the upper surface of t...

Embodiment 2

[0088] A preparation method of gallium-doped polycrystalline silicon ingot, comprising the following steps:

[0089] 1. Feeding: Before feeding, the quartz crucible of G5 type (840mm×840mm inner diameter) is coated with silicon nitride, the thickness of the silicon nitride coating is 50 μm, and the purity is greater than 99.99%; 300kg of polysilicon material and 10g of Metal gallium dopant is put into described quartz crucible (in the silicon material of every cubic centimeter, the atomic volume concentration of gallium is 6.68E+17atoms / cm 3 ), so that the target resistivity of the tail of the polysilicon ingot is 2.6 Ω cm; the ingot furnace of the ingot furnace is also provided with a continuous feeding device, and the second polysilicon polysilicon melting is put into the continuous feeding device material;

[0090] 2. Melting: Transfer the crucible filled with raw materials to the ingot casting furnace with a forklift, and vacuumize the ingot casting furnace body, inject a...

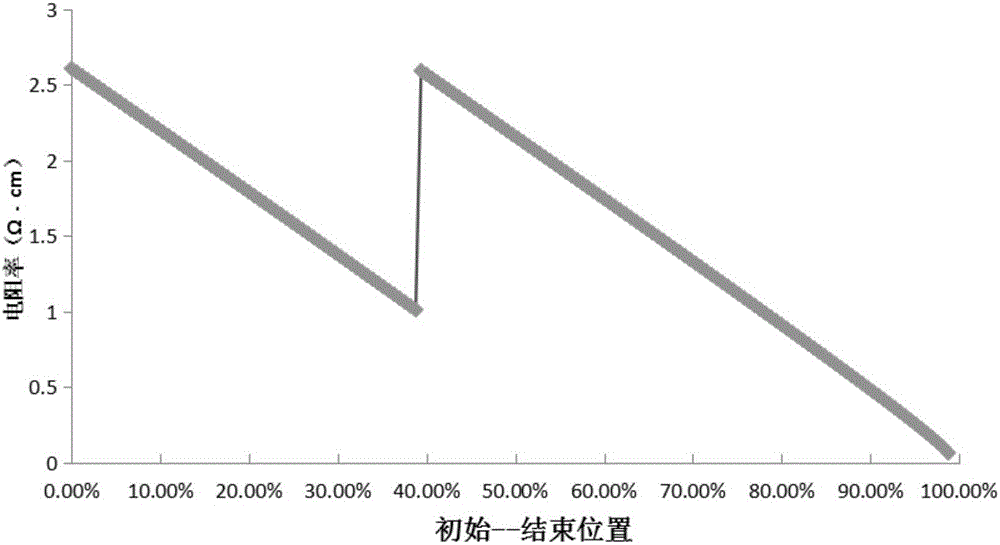

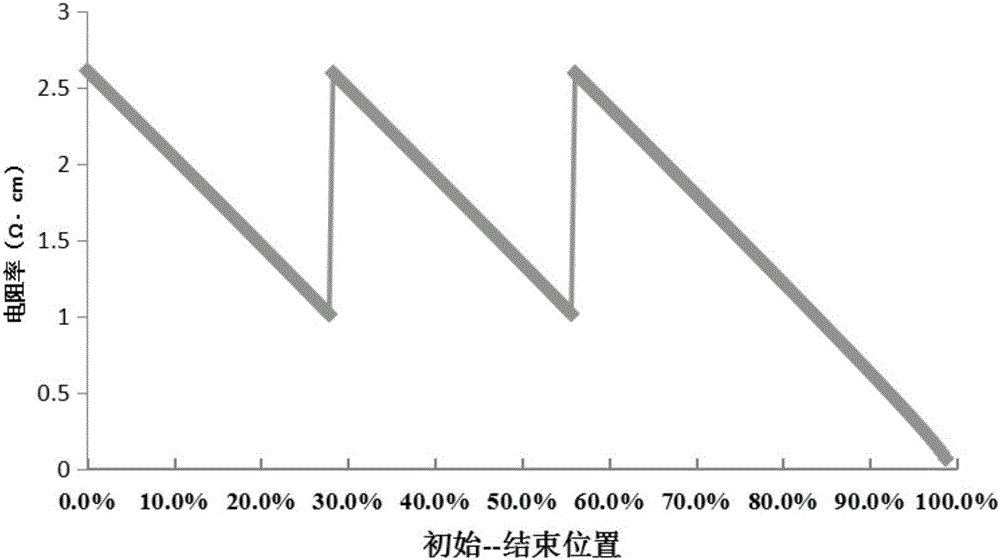

Embodiment 3

[0099] A preparation method of gallium-doped polycrystalline silicon ingot, comprising the following steps:

[0100] Wherein, step 1-3 is with embodiment 2;

[0101] 4. Feeding for the first time: When the silicon melt crystallizes to 12cm, the weight of the crystallized silicon melt reaches 195kg, and the mass of the remaining silicon melt is 105Kg. At this time, the resistivity of the crystal reaches a critical The resistivity is 1.0Ω·cm, and 195Kg of polysilicon material is added to the crucible using a continuous feeding device, so that the resistivity of the crystal reaches the target resistivity of 2.6Ω·cm when the second crystal growth begins;

[0102] 5. Suspend the opening of the heat insulation cage, re-control the power of the heater, gradually increase the temperature in the furnace to 1500°C, and gradually melt the newly added polysilicon material in the crucible;

[0103] 6. The second crystal growth: when the newly added polysilicon material is completely melte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com