Diameter transitional czochralski silicon growing method

A Czochralski monocrystalline silicon growth method technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as waste, increase production time, and reduce production efficiency, so as to reduce production costs and material waste , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

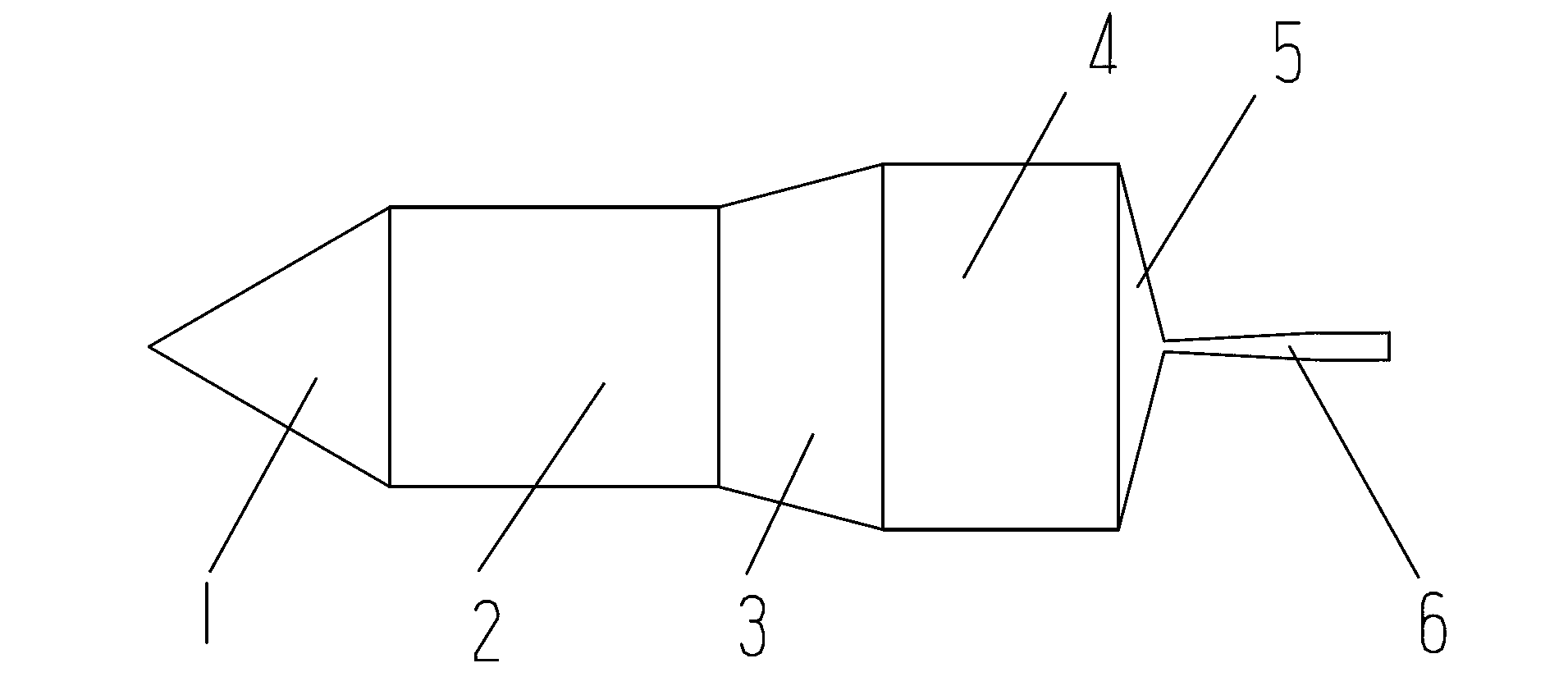

[0027] Embodiment 1, as figure 1 The single crystal silicon rod shown (i.e. No. 1 crystal rod):

[0028] 1. The 8-inch single crystal growth process is adopted, the target resistivity is 58Ω·cm, the pulling speed is 0.5~1.2mm / min, the crystal rotation is 10~20rpm, the crucible rotation is 6~12rpm, and the argon gas flow rate is 30~80slpm. The pressure in the furnace is 12~20torr.

[0029] 2. According to the distribution of the axial resistivity of the 8-inch crystal ingot from the beginning to the end, and the customer's relatively concentrated demand for 8-inch silicon wafers with a resistivity above 55Ω·cm and 6-inch silicon wafers with a resistivity of 45~55Ω·cm, the design Set the equal-diameter length L of an 8-inch single crystal to be 150mm (ie figure 1 The length of the equal-diameter section I4 of No. 1 crystal rod is 150mm).

[0030] 3. When the 8-inch single crystal grows to the target length of 150mm, the resistivity decreases to about 55Ω·cm, and the diameter ...

Embodiment 2

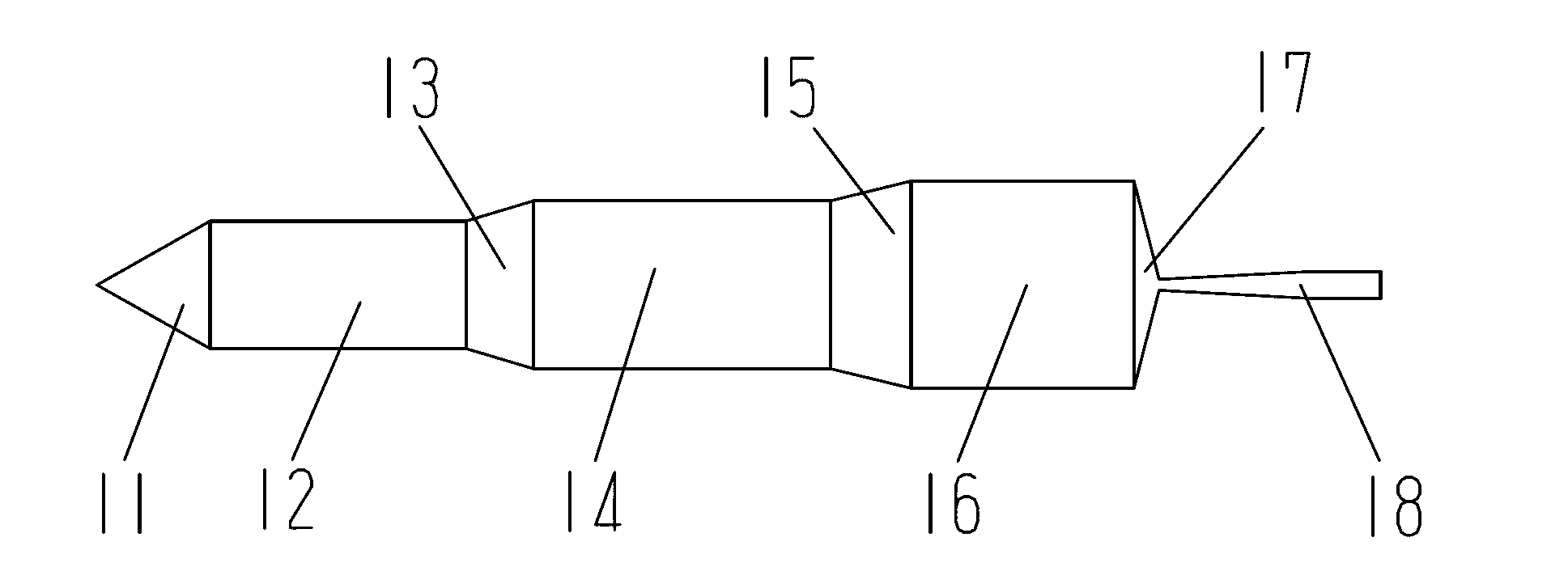

[0034] Embodiment 2, as figure 2 The single crystal silicon rod shown (i.e. No. 2 crystal rod):

[0035] 1. Using a 5-inch single crystal growth process, the target resistivity is 54Ω·cm, the pulling speed is 0.6~1.6mm / min, the crystal rotation is 10~20rpm, the crucible rotation is 6~12rpm, and the argon gas flow rate is 30~80slpm. The pressure in the furnace is 12~20torr.

[0036] 2. According to the distribution of the axial resistivity of the 5-inch ingot from the beginning to the end, and the customer's relatively concentrated demand for 5-inch silicon wafers with a resistivity above 40Ω·cm and 4-inch silicon wafers with a resistivity of 30~40Ω·cm, the design Set the equal-diameter length L of a 5-inch single crystal to be 320mm (ie figure 2 The length of the equal-diameter section I16 of No. 2 crystal rod is 320mm).

[0037] 3. When the equal diameter of the 5-inch single crystal grows to the target length of 320mm, the resistivity drops to about 40Ω·cm at this time,...

Embodiment 3

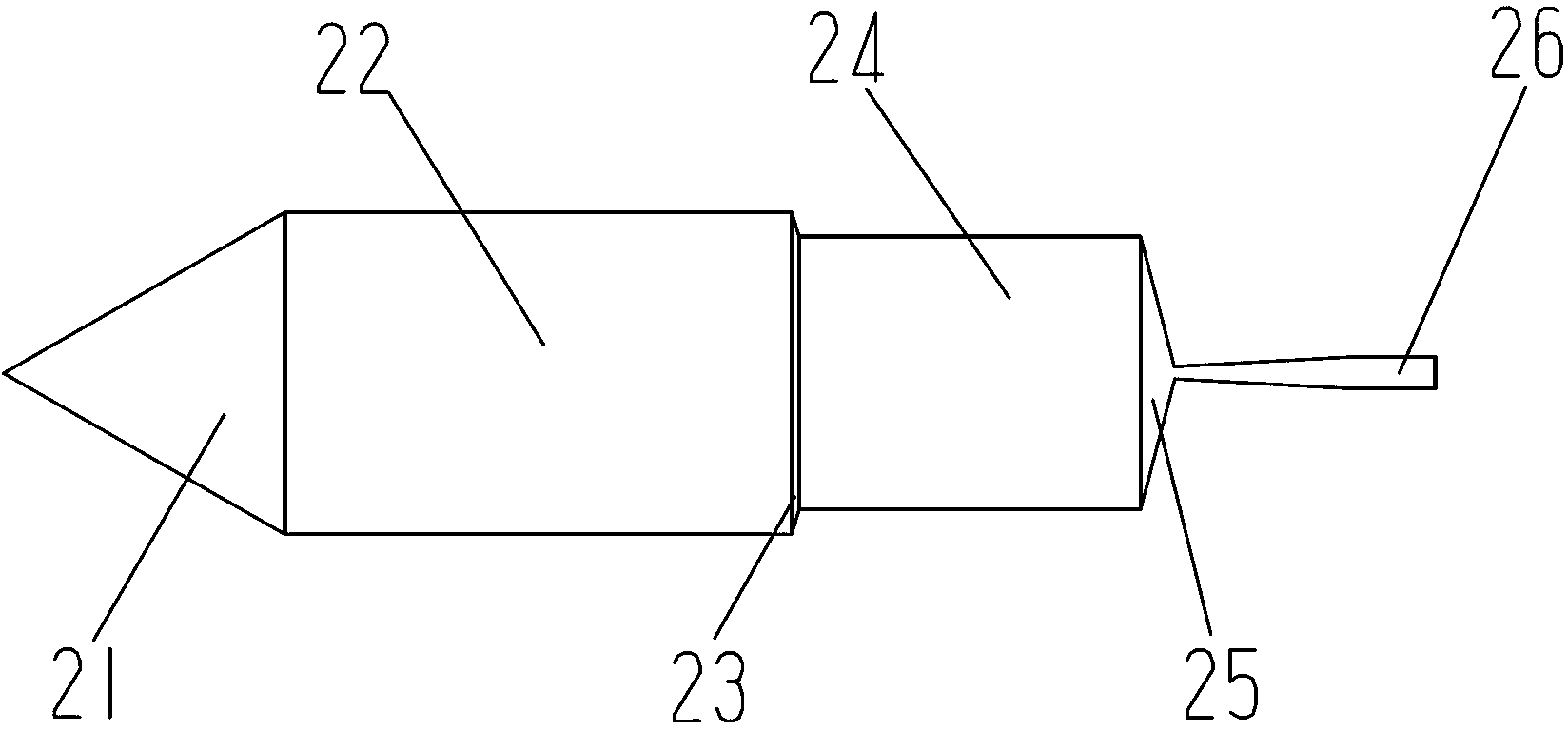

[0045] Embodiment 3, as image 3 The single crystal silicon rod shown (that is, No. 3 crystal rod):

[0046] 1. Using a 5-inch single crystal growth process, the target resistivity is 64Ω cm, the pulling speed is 0.6~1.6mm / min, the crystal rotation is 10~20rpm, the crucible rotation is 6~12rpm, and the argon gas flow rate is 30~80slpm. The pressure in the furnace is 12~20torr.

[0047] 2. Although the market has more demand for 5-inch silicon wafers with a resistivity of 40Ω·cm or more, sometimes customers have more concentrated demand for 5-inch silicon wafers with a resistivity of 55~65Ω·cm. The demand for 55Ω·cm 6-inch silicon wafers is also relatively concentrated. No matter whether it is single-drawing 6-inch single crystal, single-drawing 5-inch single crystal, or pulling 6-inch single crystal first and then turning it into 5-inch single crystal, it cannot be very good. Satisfying the concentrated demand for this grade of resistivity silicon wafers will easily lead to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com