Monocrystalline silicon growth ultrasonic wave oxygen control method

An ultrasonic and monocrystalline silicon technology, applied in the field of ultrasonic oxygen control for monocrystalline silicon growth, can solve the problems of difficulty in obtaining high magnetic field strength, large power consumption, and huge equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

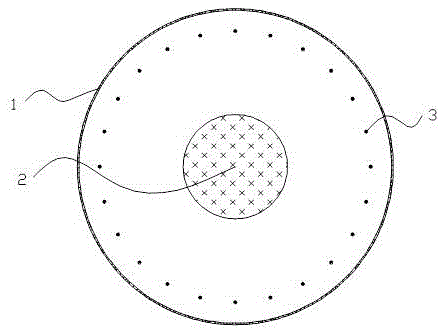

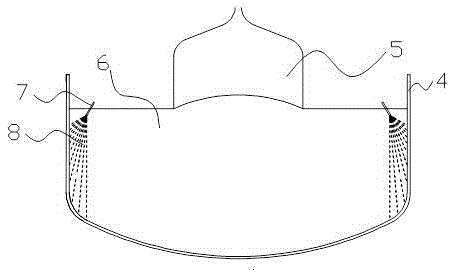

[0024] Growth diameter of 2 inches of single crystal silicon. The diameter of the quartz crucible is 155 mm, the diameter of the vibration head is 135 mm, and the distance between the vibration heads is 20 mm. After the polysilicon is completely melted, stand still for 3h. When the surface of the silicon liquid is still, the ultrasonic vibration head made of high-purity quartz material is inserted into the melt at an angle of 90o, and the depth is 10mm. Use 100% sine wave to measure the ultrasonic sound intensity at the predetermined position of the crystal growth bright ring. When the intensity exceeds 1000Pa, adjust the frequency and amplitude to make the intensity less than 1000Pa. After confirming that the ultrasonic amplitude is 1500kHz, turn off the ultrasonic wave. Before the start of isometric growth after the crystal shoulder is turned, start the ultrasonic input and start the crystal isometric growth at the same time. During the crystal growth process, the ultraso...

Embodiment 2

[0026] Growth diameter of 4 inches of single crystal silicon. The diameter of the quartz crucible is 210 mm, the diameter of the vibrating head is 190 mm, and the distance between the vibrating heads is 20 mm. After the polysilicon is completely melted, stand still for 3h. When the surface of the silicon liquid is still, the ultrasonic vibration head made of high-purity quartz material is inserted into the melt at an angle of 60o, and the depth is 10mm. The ultrasonic composition used includes: 60% sine wave, 20% square wave, and 20% sawtooth wave. Measure the ultrasonic sound intensity at the predetermined position of the bright ring of crystal growth. When the intensity exceeds 1000Pa, adjust the frequency and amplitude to make the intensity less than 1000Pa. After confirming that the ultrasonic amplitude is 1500kHz, turn off the ultrasonic wave. Before the start of isometric growth after the crystal shoulder is turned, start the ultrasonic input and start the crystal isom...

Embodiment 3

[0028] Growth diameter of 4 inches of single crystal silicon. The diameter of the quartz crucible is 210 mm, the diameter of the vibration head is 190 mm, and the distance between the vibration heads is 40 mm. After the polysilicon is completely melted, stand still for 3h. When the surface of the silicon liquid is still, the ultrasonic vibration head made of high-purity quartz material is inserted into the melt at an angle of 90o, and the depth is 10mm. The ultrasonic composition used includes: 60% sine wave, 30% square wave, and 10% sawtooth wave. Measure the ultrasonic sound intensity at the predetermined position of the bright ring of crystal growth. When the intensity exceeds 1000Pa, adjust the frequency and amplitude to make the intensity less than 1000Pa. After confirming that the ultrasonic amplitude is 1000kHz, turn off the ultrasonic wave. Before the start of isometric growth after the crystal shoulder is turned, start the ultrasonic input and start the crystal isom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com