Sound insulation mortar and sound insulation floor structure system

A sound insulation and mortar technology, which is applied in the direction of floors, sound insulation, floors, etc., can solve the problems of poor compatibility between the elastic sound insulation layer and cement mortar, high flatness requirements of the base layer, and sound bridges affecting the sound insulation effect, etc., to achieve saving Construction cost, high effective height, and the effect of avoiding easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

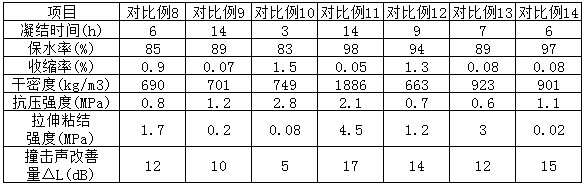

Examples

Embodiment 1

[0028] This embodiment provides a kind of sound insulation mortar, and this sound insulation mortar is made by mixing the raw materials comprising the following parts by weight:

[0029] 500 parts of cement, 450 parts of elastic damping aggregate, 45 parts of viscosifying additive, 270 parts of river sand, 1 part of water-retaining thickening additive, and the water-binder ratio of the sound-proof mortar is 1:0.3; the cement uses 42.5R silicic acid salt cement.

[0030] Wherein, the elastic damping aggregate includes rubber powder and rubber granules, the mass ratio of rubber powder and rubber granules is 2.5:1; the mesh number of rubber powder is 40-120, and the mesh number of rubber granules is 1-3;

[0031] The main components of rubber powder and rubber granules are natural rubber, butadiene rubber and styrene-butadiene rubber;

[0032] The mesh number of river sand is 40-70;

[0033] The tackifier is dispersible latex powder;

[0034] The water-retaining thickener is a...

Embodiment 2

[0036] This embodiment provides a kind of sound insulation mortar, and this sound insulation mortar is made by mixing the raw materials comprising the following parts by weight:

[0037] 500 parts of cement, 450 parts of elastic shock-absorbing aggregate, 45 parts of thickening additive, 270 parts of river sand, 1 part of water-retaining thickening aid, 1 part of nano-alumina, 3 parts of polyether ether ketone powder, and sound-proof mortar The water-cement ratio is 1:0.3; the particle size of polyetheretherketone powder is 120-150μm, and the cement is 42.5R Portland cement.

[0038] Wherein, the elastic damping aggregate includes rubber powder and rubber granules, the mass ratio of rubber powder and rubber granules is 2.5:1; the mesh number of rubber powder is 40-120, and the mesh number of rubber granules is 1-3;

[0039] The mass ratio of polyetheretherketone powder and nano-alumina is 3:1;

[0040] The mesh number of river sand is 40-70;

[0041] The tackifier is dispers...

Embodiment 3

[0044] The difference between Example 3 and Example 2 is that the content of each component and the physical parameters of the sound insulation mortar are different, see Table 1 for details; wherein the water-retaining thickener is hydroxyethyl methyl cellulose ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com