Vacuum pump configuration structure with noise reduction function and using method thereof

A configuration structure, vacuum pump technology, applied in the direction of parts, pumps, pump components, etc. of the pumping device used for elastic fluid, can solve the problems of unfavorable heat dissipation, lack of noise reduction function, etc., to reduce the intensity of sound waves and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

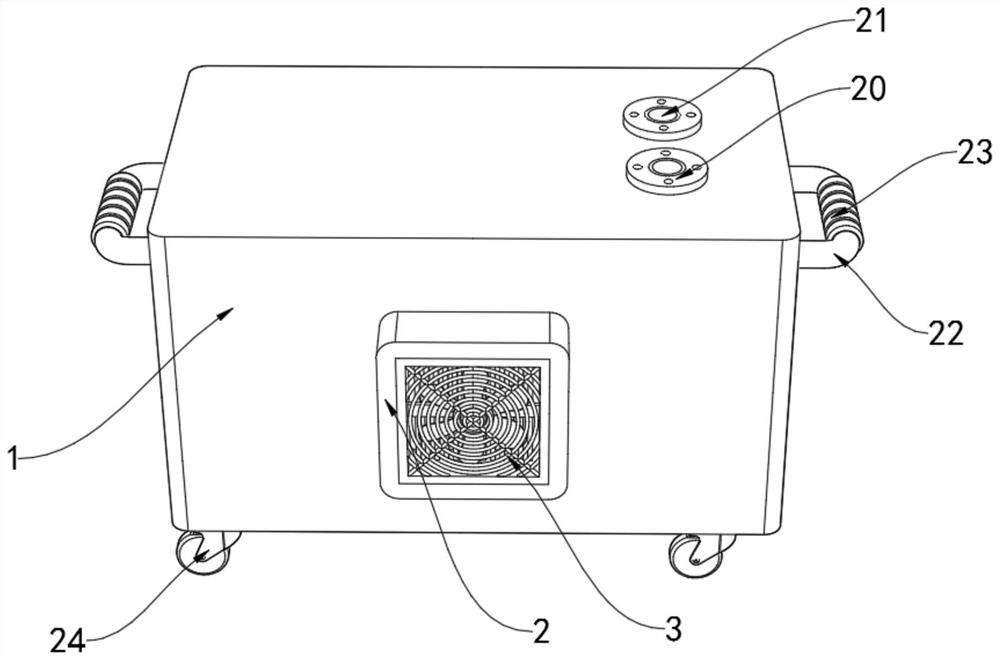

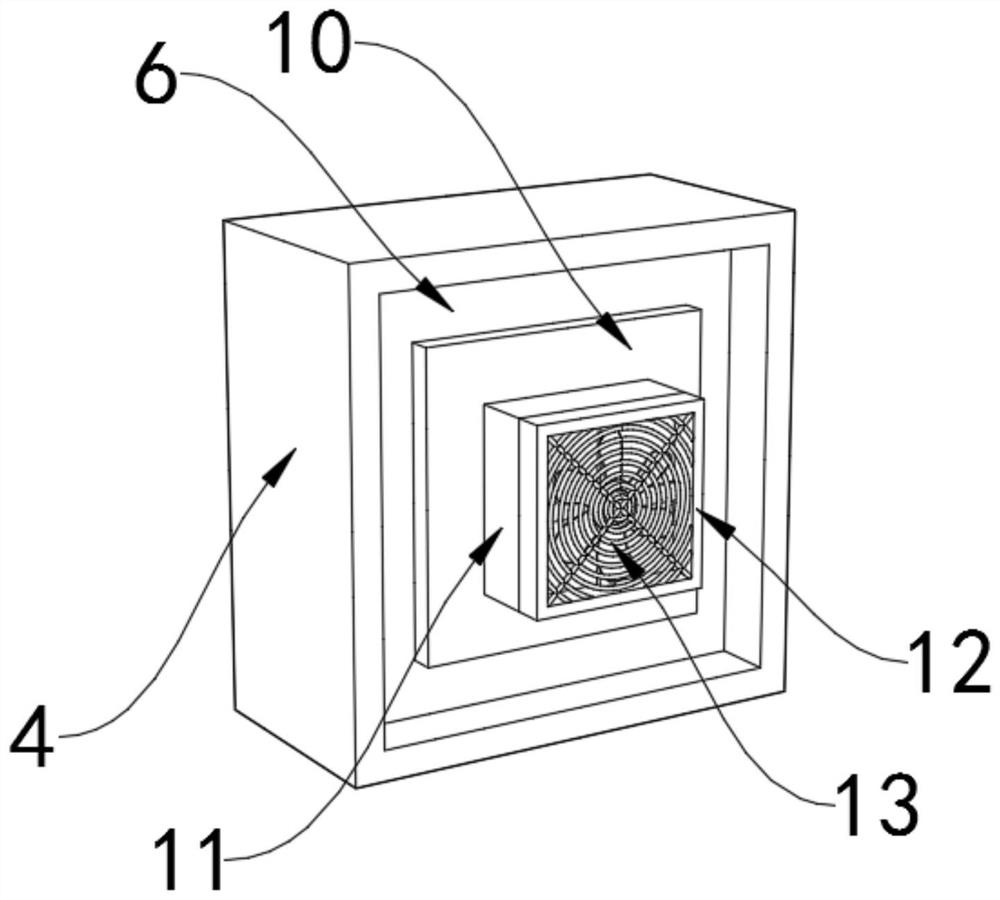

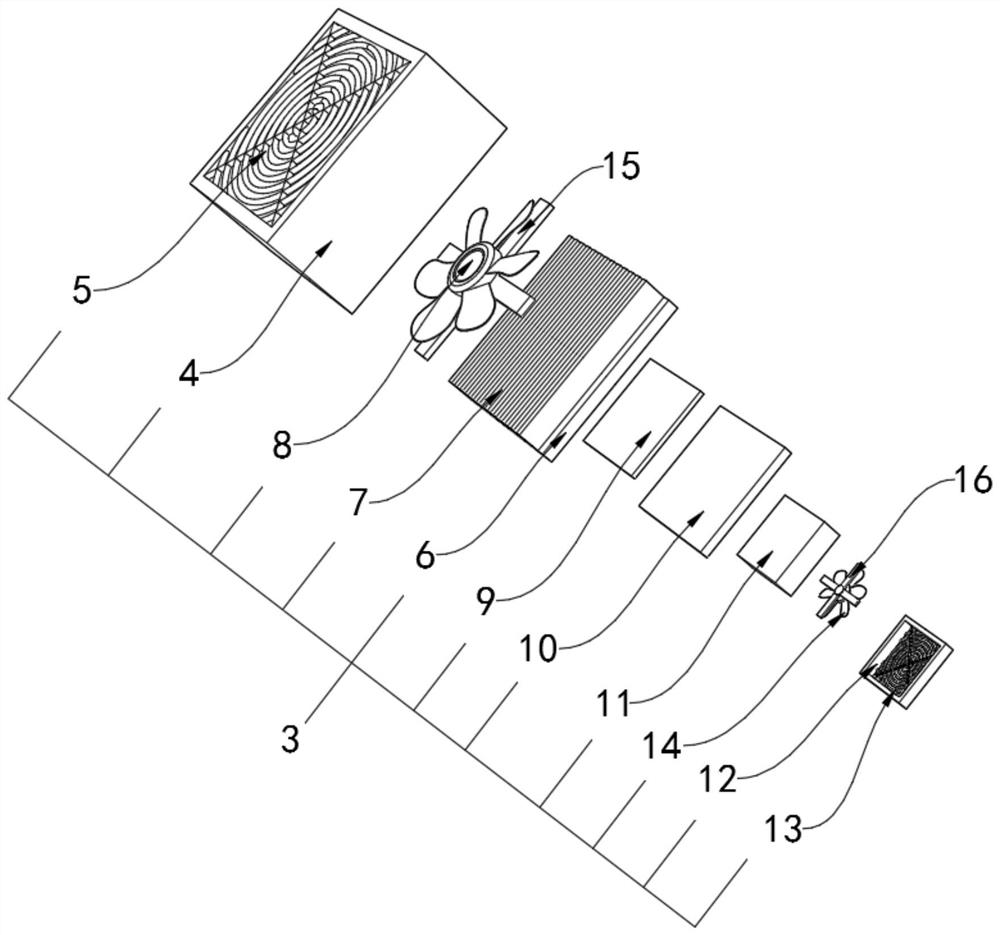

[0037] see Figure 1-6As shown, the present invention is a vacuum pump configuration structure with a noise reduction function, including a protective outer box 1, fixed frames 2 are fixed on both sides of the protective outer box 1, and the two sides of the protective outer box 1 correspond to the fixed frame 2. A through hole with the same inner diameter as the fixed frame 2 is provided at the position, and a refrigeration mechanism 3 is fixed on the inside of the fixed frame 2, and the refrigeration mechanism 3 includes a first connection frame 4, a first filter screen cover 5, a cooling fin 6, a cooling fin 7, Radiating fan 8, heat insulation pad 9, connection plate 10, cold conduction block 11, second connection frame 12, second filter screen cover 13 and conduction cooling fan 14, the first connection frame 4 is fixed on the inner side of the fixed frame 2, the second Connect by welding between a connection frame 4 and the fixed frame 2, the first filter screen cover 5 i...

Embodiment 2

[0042] On the basis of the first embodiment above, a method for using a vacuum pump configuration structure with a noise reduction function is disclosed, the steps of which are as follows:

[0043] Step 1: Choose to push the handle 22 or lift the handle 22 to move the position of the device according to actual needs;

[0044] Step 2: Drive the main body of the vacuum pump 19 to make the main body of the vacuum pump 19 work. When the main body of the vacuum pump 19 operates, noise is generated, and the noise is transmitted to the sound-absorbing cotton pad 18 through the reflection of the fibers, mutual superposition, and collision, and the sound wave energy is converted into heat energy to reduce the sound wave intensity. , to achieve the effect of noise reduction;

[0045] Step 3: connect the refrigerating sheet 6 to direct current, so that the temperature of one side of the refrigerating sheet 6 rises, and the temperature of the other side of the refrigerating sheet 6 drops....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com