Closed monocrystalline growth furnace for molten salt method crystal growth

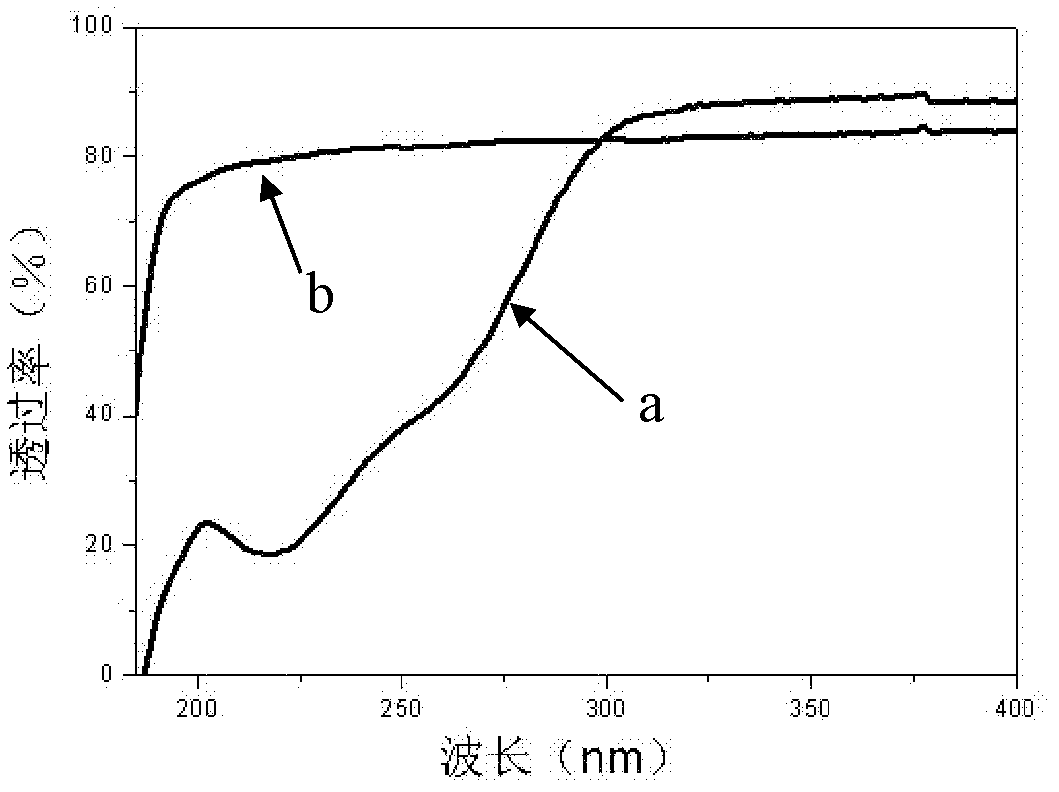

A technology of crystal growth and molten salt method, which is applied in the direction of crystal growth, single crystal growth, and melt from molten solvent, etc. It can solve the problems that cannot be achieved, cannot change the growth atmosphere, etc., and achieve optical performance improvement and UV non-toxicity removal. Intrinsic absorption, the effect of improving optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

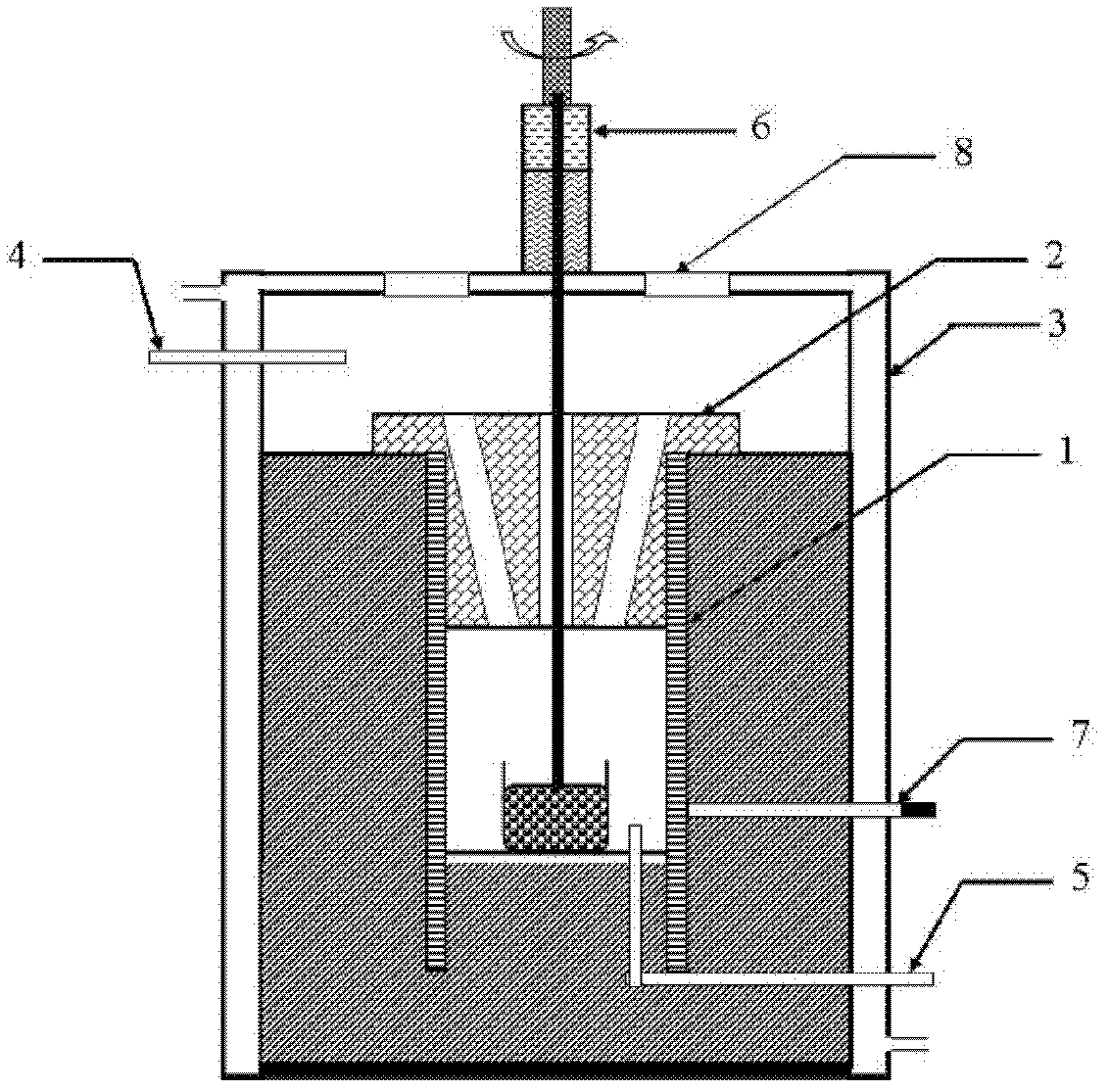

[0039] The closed single crystal growth furnace used for the molten salt method crystal growth of the present embodiment, such as figure 1 As shown, it comprises: a ceramic sleeve type furnace 1 with an inner diameter of 100mm (80mm-150mm is acceptable), a height of 300mm (300-500mm is acceptable), and the stainless steel outer furnace shell 3 is directly filled with refractory insulation cotton; Stainless steel outer furnace shell 3 inner diameter 350mm (300-700mm all can be), high 450mm (400-800mm all can); This stainless steel outer furnace shell 3 is the airtight barrel-shaped hollow double-layer stainless steel outer shell of double-layer hollow stainless steel making, its The barrel wall, barrel bottom and barrel cover are provided with connected closed flow passages; the closed flow passages are equipped with circulating cooling water; the air inlet 4 is located above the side wall of the stainless steel outer furnace shell 3, and the air inlet 5 is located on the stainl...

Embodiment 2

[0045] The closed single crystal growth furnace used for the molten salt method crystal growth of the present embodiment, such as figure 1 As shown, it includes: the inner diameter of the ceramic casing furnace 1 is 110mm (80mm-150mm), the height is 350mm (300-500mm is acceptable), and the refractory insulation cotton is directly filled between the stainless steel outer furnace shell 3; the stainless steel outer furnace shell 3 The inner diameter is 400mm (300-700mm is acceptable), the height is 500mm (400-800mm is acceptable), and the stainless steel outer furnace shell 3 is a closed barrel-shaped hollow double-layer stainless steel outer furnace shell made of double-layer hollow stainless steel. The bottom and the barrel cover are provided with a connected closed flow channel; the closed flow channel is equipped with circulating cooling water; the air inlet 4 is located above the side wall of the stainless steel outer furnace shell 3, and the air inlet 5 is located on the sid...

Embodiment 3

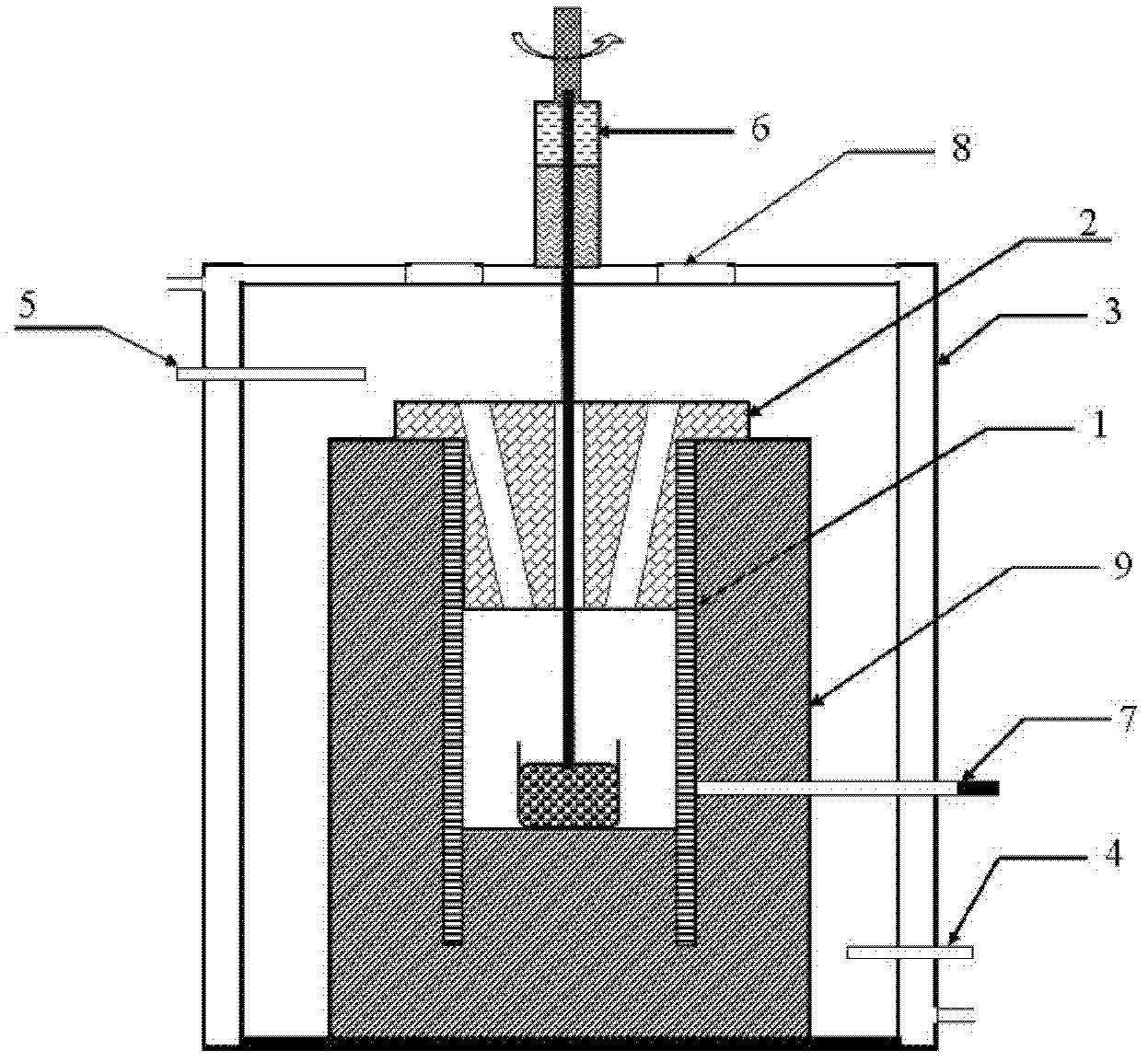

[0051] The airtight growth furnace used for growing molten salt single crystal in this embodiment, such as figure 2 As shown, it comprises: the inner diameter of the ceramic casing furnace 1 is 120mm (80mm-150mm), and the height is 380mm (300-500mm can be used), and a non-airtight stainless steel furnace shell 9 is set outside the refractory insulation cotton; the non-airtight There is a space layer between the stainless steel furnace shell 9 and the inner wall of the stainless steel outer furnace shell 3; the inner cavity of the stainless steel outer furnace shell 3, the non-sealed stainless steel furnace shell 9 and the ceramic sleeve type furnace 1 are filled with atmospheric gas; the ceramic sleeve A refractory and heat-preserving brick furnace cover 2 is placed above the tubular furnace 1, and a first vertical central through hole (Φ=16mm, 10-20mm is acceptable) is arranged in the middle, and there is a crystal growth observation hole on each side of it; the stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com