Preparation method of nickel titanate/titanium dioxide composite nanomaterial

A technology of composite nanomaterials and titanium dioxide, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of product without fixed shape, high reaction temperature, particle agglomeration, etc., and achieve the production cost Low, easy to control, high catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Slowly add the isopropanol solution of nickel acetylacetonate with a concentration of 0.2 mol / L to the isopropanol solution of titanium acetylacetonate with a concentration of 0.2 mol / L, and dissolve and mix evenly in the alcohol solution. The resulting mixed solution was subjected to a cross-linking reaction at a reaction temperature of 200 °C and a reaction time of 4 hours, wherein the molar ratio of nickel acetylacetonate to titanium acetylacetonate was 1:2. After the cross-linking reaction, the high-temperature reaction was carried out in the muffle furnace. The high-temperature reaction temperature was 600 °C and the reaction time was 24 h. After natural cooling, the target product is obtained.

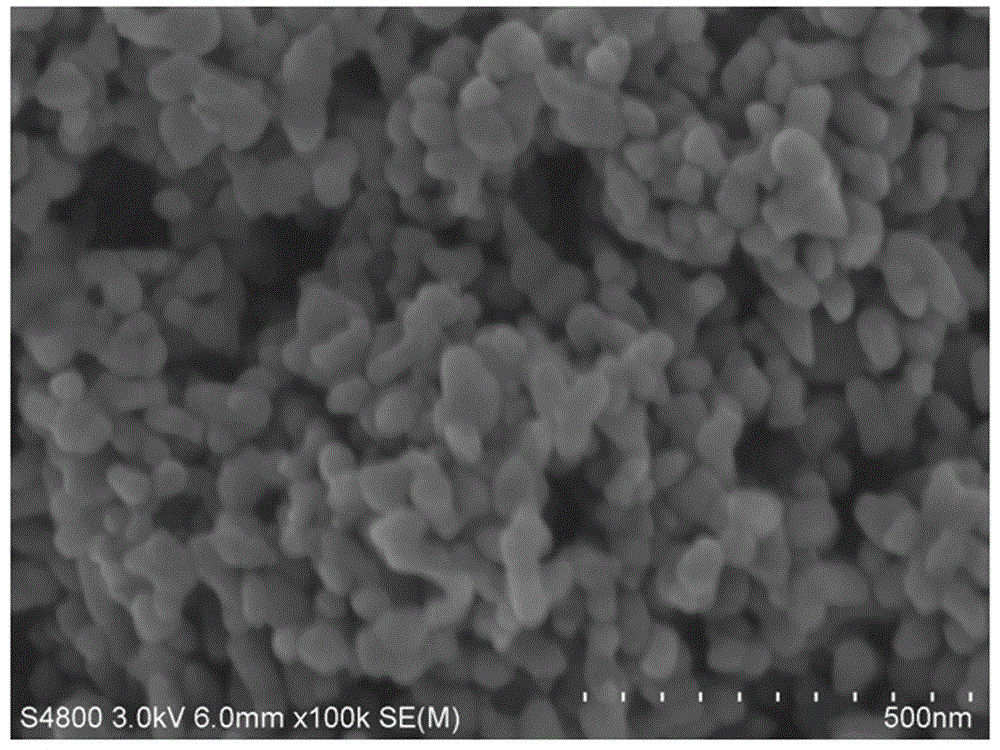

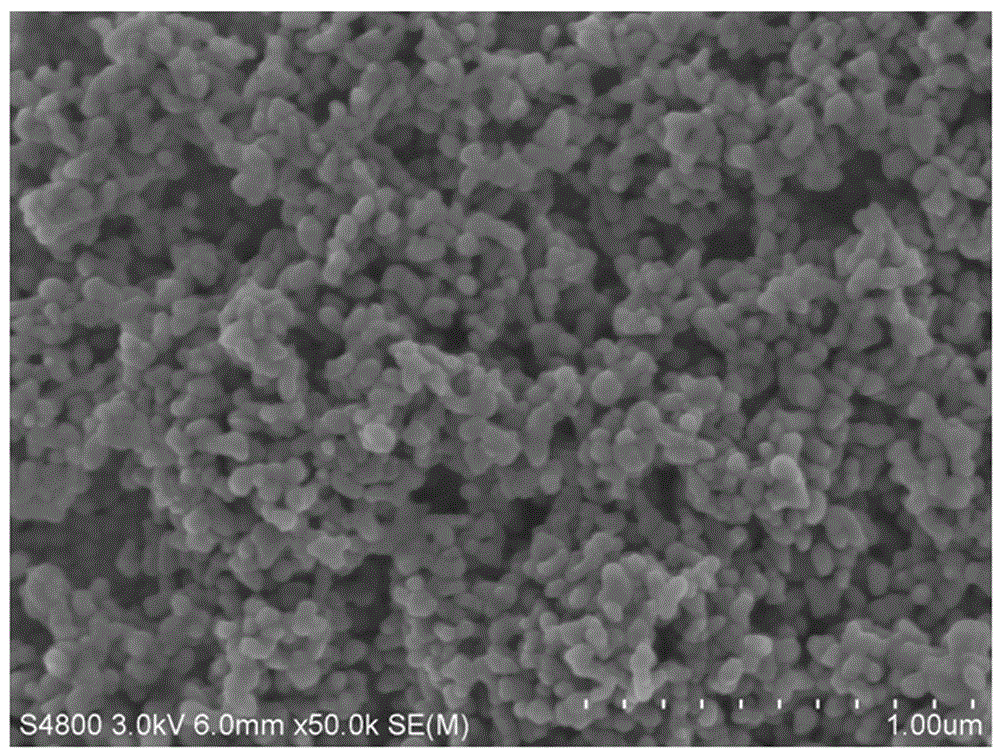

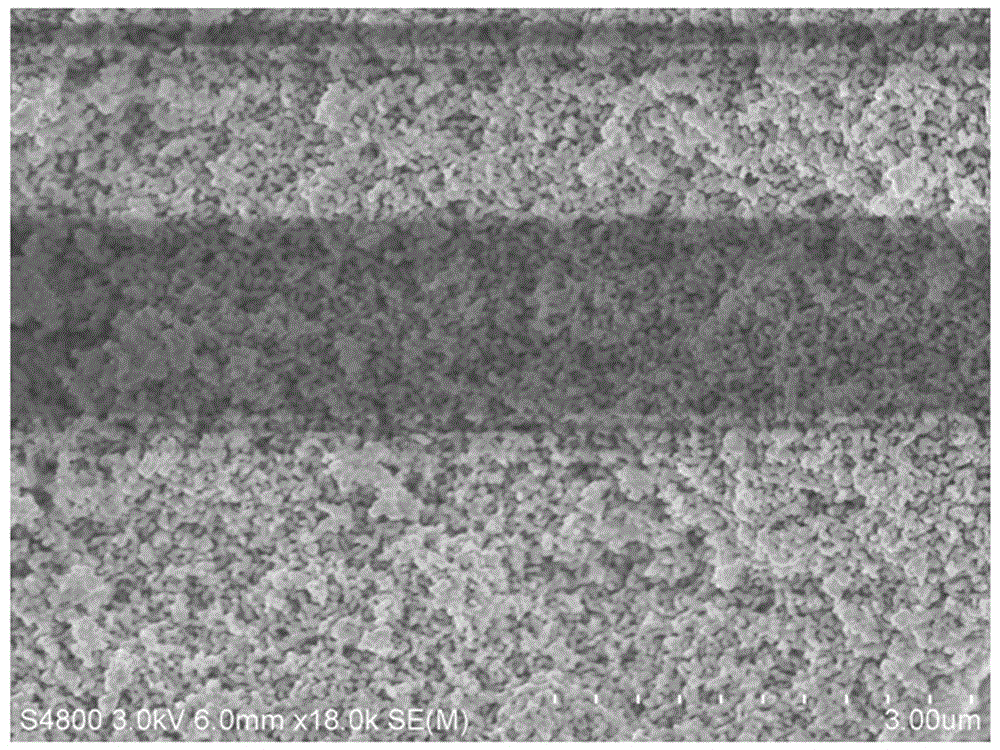

[0031] The particle size of the product is between 50-70nm, and the yield of the product is 99.6%. The product purity is 99.8%, impurity content: carbon is less than 0.2%. The prepared nickel titanate / titanium dioxide composite nanomaterial was used as a photocatalyst (0...

Embodiment 2

[0033] Slowly add the methanol solution of nickel acetylacetonate with a concentration of 0.2 mol / L to the methanol solution of titanium acetylacetonate with a concentration of 0.2 mol / L slowly, dissolve and mix well in the alcohol solution. The obtained mixed solution was subjected to cross-linking reaction, the reaction temperature was 300°C, and the reaction time was 8 hours, wherein the molar ratio of nickel acetylacetonate to titanium acetylacetonate was 1:2. After the cross-linking reaction, the high-temperature reaction was carried out in a muffle furnace. The high-temperature reaction temperature was 1000 °C, and the reaction time was 6 h. After natural cooling, the target product is obtained.

[0034] The particle size of the product is between 60-80nm, and the yield of the product is 99.2%. The product purity is not less than 99.7%, and the impurity content: carbon is less than 0.3%. The prepared nickel titanate / titanium dioxide composite nanomaterial was used as a...

Embodiment 3

[0036] Slowly add the ethanol solution of nickel acetylacetonate with a concentration of 0.02 mol / L to the ethanol solution of titanium acetylacetonate with a concentration of 0.02 mol / L slowly, dissolve and mix well in the alcohol solution. The resulting mixed solution was subjected to a cross-linking reaction at a reaction temperature of 150 °C and a reaction time of 8 hours, wherein the molar ratio of nickel acetylacetonate to titanium acetylacetonate was 1:2. After the cross-linking reaction, the high-temperature reaction was carried out in a muffle furnace. The high-temperature reaction temperature was 1000 °C, and the reaction time was 6 h. After natural cooling, the target product is obtained.

[0037] The particle size of the product is between 60-70nm, and the yield of the product is 99.5%. The product purity is not less than 99.6%, and the impurity content: carbon is less than 0.4%. The prepared nickel titanate / titanium dioxide composite nanomaterial was used as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com