Method for preparing titanate lamella

A technology of titanate and titanium compound, which is applied in the field of preparation of titanate lamellae, can solve problems such as brake noise cannot be effectively solved, affect the production process, and wear fast, and achieve good heat resistance and durability Improvement of wear performance, operating environment, and less wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

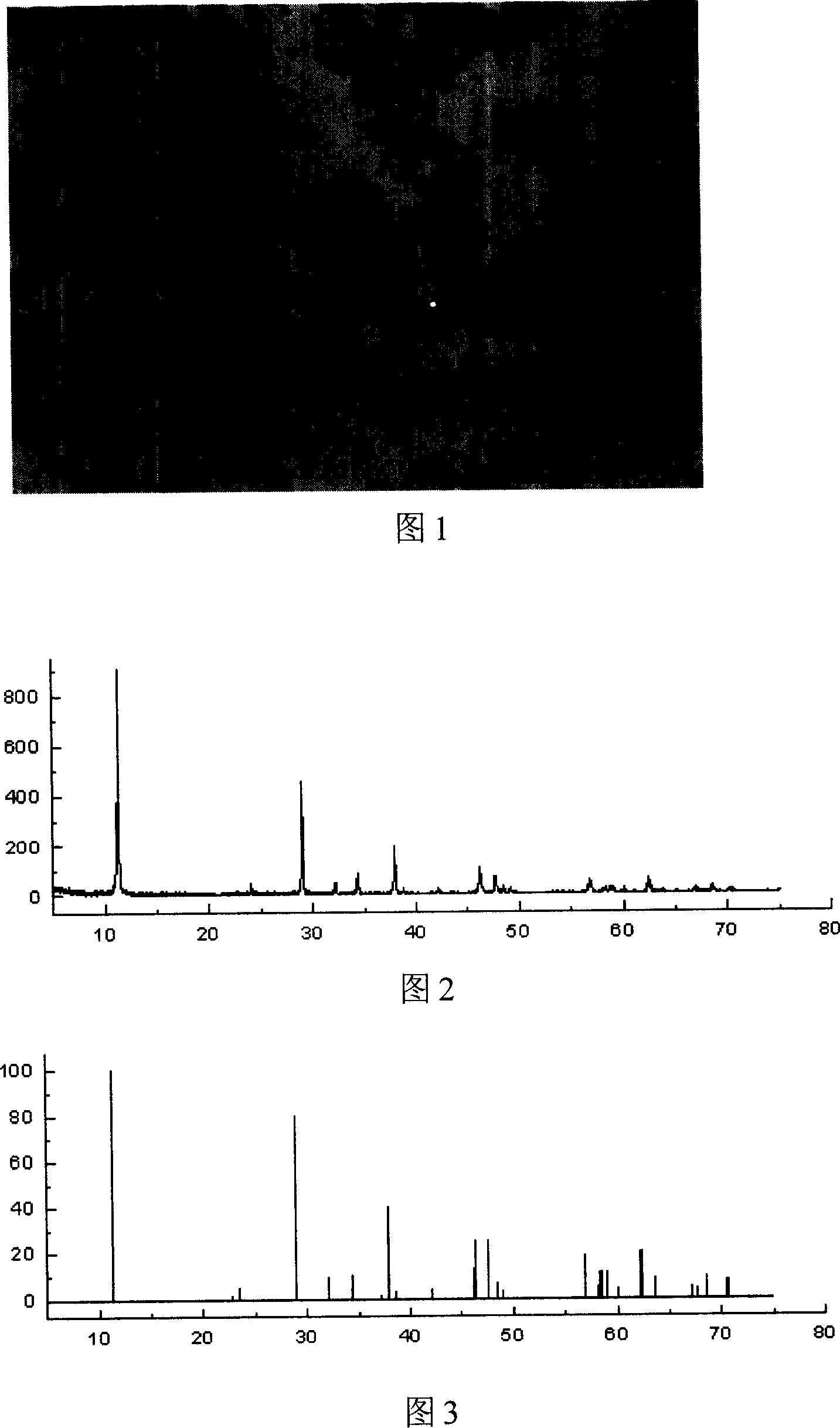

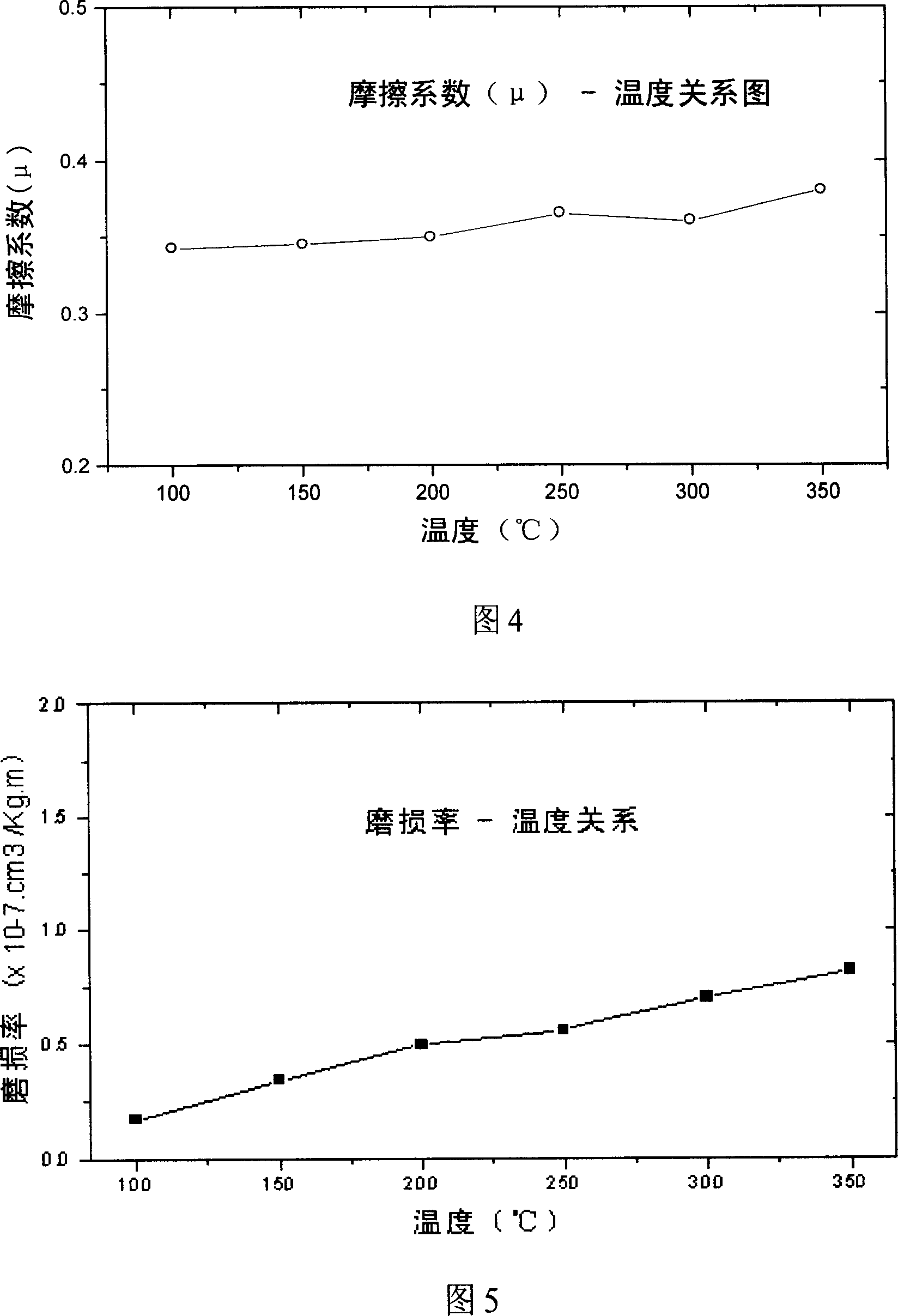

[0025] Anatase Titanium Dioxide (TiO 2 Accounting for more than 98%) 160g, potassium carbonate (K 2 CO 3 Purity above 96%) 69g formula, adding magnesium fluoride (MgF 2 , analytically pure) 31.2g and metal Mg powder 2.6g, mix evenly, put into a box-type electric furnace and heat to 950°C, keep warm for 2 hours, and then cool with the furnace; put the burnt product in 10 times (weight ratio) of water Soaked and crushed; filtered to remove water, dried in an electric oven at 110°C for 5 hours, then placed in an electric furnace, and heat-treated at 650°C for 2 hours; 216g of the obtained white powder was analyzed by X-ray diffraction, and the chemical formula is K 0.8 Mg 0.4 Ti 1.6 o 4 Titanate (as shown in Figure 2 and Figure 3), the calculated yield is 95%. It is observed as lamellar crystals with a transmission microscope (as shown in Figure 1), and the average size is measured: the length and width are about 6 μm, and the average thickness is about 0.4 μm.

Embodiment 2

[0027] The raw material formula is the same as in Example 1, heated to 1000° C. in a box-type electric furnace, kept for 2 hours, and then cooled with the furnace; the rest of the operations are the same as in Example 1. Obtain white powder 218g, through X-ray diffraction analysis, it is that chemical formula is K 0.8 Mg 0.4 Ti 1.6 o 4 Titanate, the calculated yield is 96%. Observed as lamellar crystals with a transmission microscope, the average size measured: the length and width are about 8 μm, and the average thickness is about 0.5 μm.

Embodiment 3

[0029] The raw material formula is the same as in Example 1, heated to 1050°C in a box-type electric furnace, kept for 3 hours, and then cooled with the furnace; all the other operations are the same as in Example 1; 210g of white powder is obtained, and through X-ray diffraction analysis, the chemical formula is K 0.8 Mg 0.4 Ti 1.6 o 4 Titanate, the calculated yield is 93%. Observed as lamellar crystals with a transmission microscope, the measured average size: the length and width are about 12 μm, and the average thickness is about 0.6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com