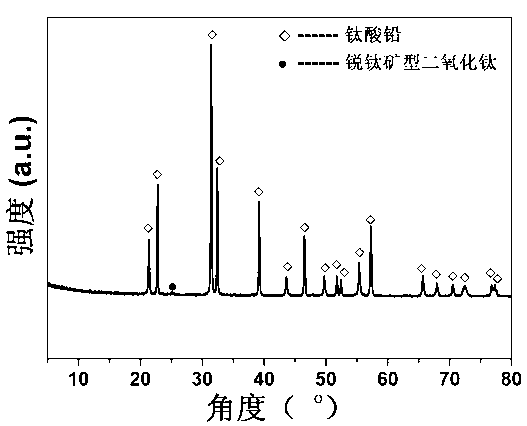

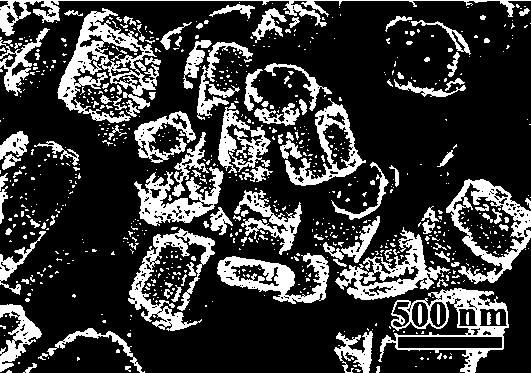

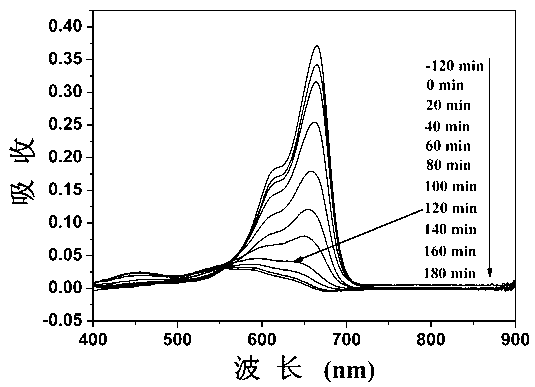

Titanium dioxide/lead titanate compounded nanometer photocatalyst and preparation method thereof

A nano-photocatalyst and titanium dioxide technology, which is applied in the fields of inorganic non-metallic materials and nano-photocatalytic materials, can solve the problems of less research on influence and mechanism, difficult absorption of visible light, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) 0.2 g monodisperse single crystal single domain perovskite phase PbTiO prepared by hydrothermal method 3 Add single crystal nanosheets into deionized water and disperse ultrasonically for 15 minutes to make them evenly dispersed;

[0020] 2) Configure 0.005 mol / L TiF 4 aqueous solution;

[0021] 3) The TiF of step 2) 4 The aqueous solution is added to the solution obtained in step 1), and then transferred to the polytetrafluoroethylene reactor liner, and the volume is adjusted to 2 / 3 of the reactor volume with deionized water, and stirred for 5 minutes to obtain a suspension;

[0022] 4) Place the reactor liner equipped with reaction materials in step 3) in the reactor, airtight, and place at 160 o Keep warm in the furnace of C, after reacting for 10 minutes, place in the air to cool down to room temperature naturally, take out the reaction product, filter, wash with deionized water, and dry to obtain titanium dioxide / lead titanate composite nano photocatalyst.

Embodiment 2

[0024] 1) 0.5 g monodisperse single-crystal single-domain perovskite phase PbTiO prepared by hydrothermal method 3 Add single crystal nanosheets into deionized water and disperse ultrasonically for 15 minutes to make them evenly dispersed;

[0025] 2) Configure 0.02 mol / L TiF 4 aqueous solution;

[0026] 3) The TiF of step 2) 4 The aqueous solution was added to the solution obtained in step 1), and then transferred to the polytetrafluoroethylene reactor liner, and the volume was adjusted to 4 / 5 of the reactor volume with deionized water, and stirred for 5 minutes to obtain a suspension;

[0027] 4) Place the reactor liner equipped with reaction materials in step 3) in the reactor, airtight, and place at 180 o Keep warm in the furnace of C, after reacting for 60 minutes, place in the air and cool down to room temperature naturally, take out the reaction product, filter, wash with deionized water, and dry to obtain titanium dioxide / lead titanate composite nano photocatalyst. ...

Embodiment 3

[0029] 1) 1.0 g monodisperse single-crystal single-domain perovskite phase PbTiO prepared by hydrothermal method 3 Add single crystal nanosheets into deionized water and disperse ultrasonically for 15 minutes to make them evenly dispersed;

[0030] 2) Configure 0.2 mol / L TiF 4 aqueous solution;

[0031] 3) The TiF of step 2) 4 The aqueous solution was added to the solution obtained in step 1), and then transferred to the polytetrafluoroethylene reactor liner, and the volume was adjusted to 4 / 5 of the reactor volume with deionized water, and stirred for 5 minutes to obtain a suspension;

[0032] 4) Place the reactor liner equipped with reaction materials in step 3) in the reactor, airtight, and place at 180 o Keep warm in the furnace of C, after reacting for 90 minutes, place it in the air to cool down to room temperature naturally, take out the reaction product, filter, wash with deionized water, and dry to obtain titanium dioxide / lead titanate composite nano photocatalyst....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com