Method for producing aluminium titanates film by using colloidal sols-gel rubber technique

A technology of aluminum titanate and xerogel film, which is applied in the field of preparing aluminum titanate film by sol-gel process, can solve the problems of high price of aluminum and titanium alkoxide, high process requirements and high preparation cost, and achieve cost Low, low process requirements, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

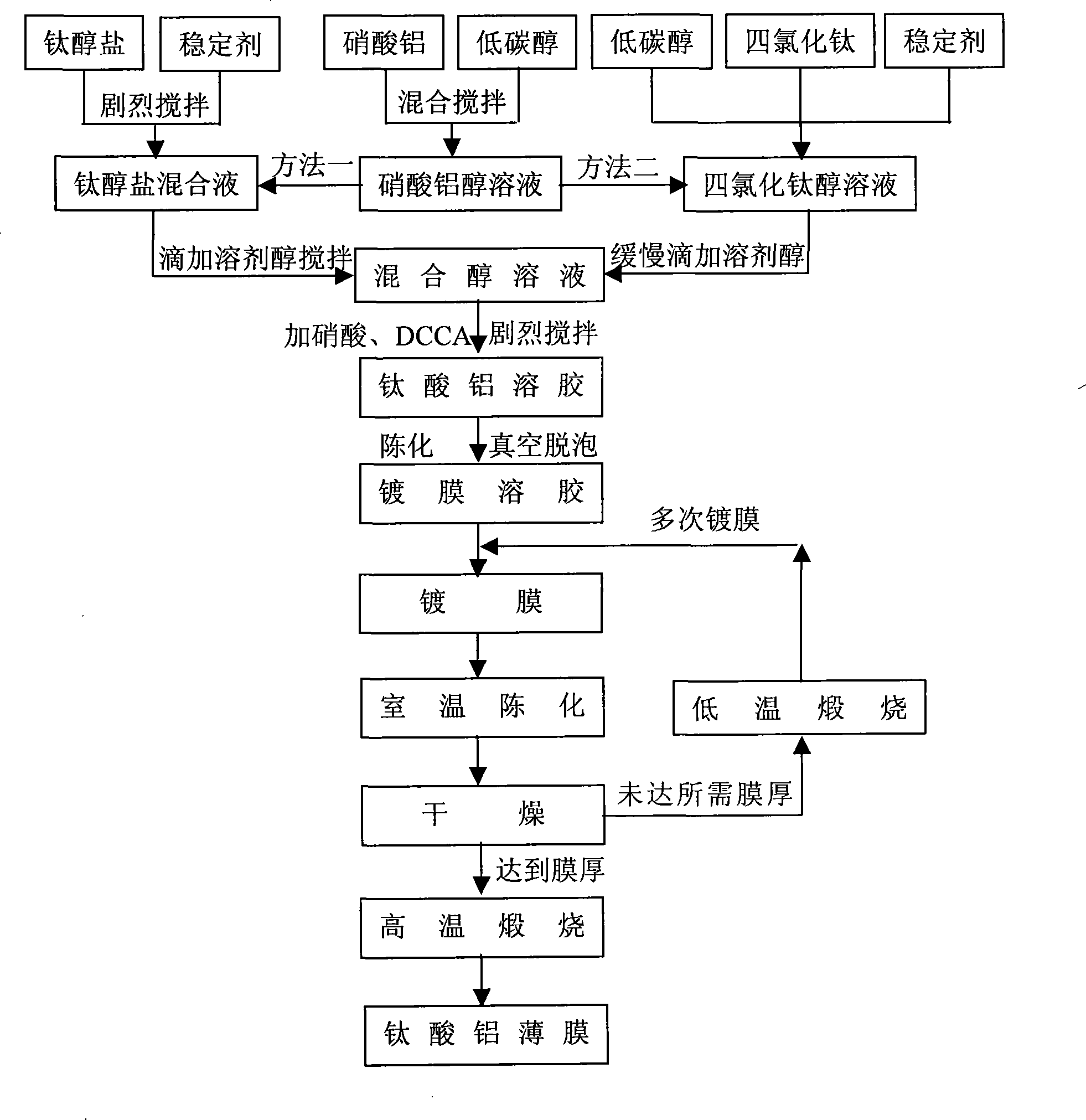

Method used

Image

Examples

Embodiment 1

[0018] Prepare aluminum titanate sol according to the molar ratio of aluminum to titanium 2:1, weigh 7.502g of aluminum nitrate (analytical pure) and dissolve it in 26.0ml of ethanol, seal it for use; mix 3.4ml of butyl titanate (chemically pure) with 1.0ml of acetyl Acetone (the molar ratio of titanium and titanium is 1:1) was mixed and vigorously stirred for 30 minutes; then the prepared aluminum nitrate ethanol solution was slowly added dropwise to the butyl titanate-acetylacetone mixture, and then slowly added dropwise 24.0ml ethanol, Add nitric acid to adjust the pH value to 1, then add 1.0ml glycerin, stir vigorously for 4 hours, and after aging for 72 hours, obtain a sol with a viscosity of 6.25mPa·s through vacuum defoaming treatment; Coating on the mullite substrate, the substrate coated with aluminum titanate sol was first aged at room temperature for 12 hours, then dried at room temperature, and finally dried at 50°C for 3 hours to obtain an aluminum titanate xerogel...

Embodiment 2

[0020] Prepare aluminum titanate sol according to the molar ratio of aluminum to titanium 2:1, weigh 15.004g of aluminum nitrate (analytical pure) and dissolve it in 50.0ml of ethanol, seal it for use; bottle, use a pipette to measure 2.2ml TiCl 4 (Chemically pure) quickly insert below the ethanol liquid level, slowly add titanium tetrachloride to obtain titanium tetrachloride ethanol solution, and then add 2.1ml acetylacetone (the molar ratio of titanium to titanium is 1:1) to obtain a blood Red solution: Slowly add the prepared aluminum nitrate ethanol solution dropwise into the prepared titanium tetrachloride ethanol solution, add nitric acid to adjust the pH value to 1, add butanediol 1.5ml, stir vigorously for 6 hours, and after aging for 48 hours, A sol with a viscosity of 17.25mPa·s was obtained by vacuum defoaming treatment; a film was coated on a silicon carbide substrate at a dipping-pulling speed of 0.5mm / s; the substrate coated with aluminum titanate sol was first ...

Embodiment 3

[0022] Prepare aluminum titanate sol according to the molar ratio of aluminum to titanium: 2:1, weigh 11.254g of aluminum nitrate (analytical pure) and dissolve it in 38ml of ethanol, seal it for use; measure 3.5ml of ethanol into a conical flask that has been cooled in an ice-water bath , use a pipette to measure 1.7ml of TiCl 4 (Chemically pure) quickly insert below the ethanol liquid level, slowly add titanium tetrachloride to obtain titanium tetrachloride ethanol solution, then add 2.3ml glacial acetic acid (the molar ratio to titanium is 2.6:1); Slowly add aluminum nitrate ethanol solution dropwise to the prepared titanium tetrachloride ethanol solution, slowly add 12ml ethanol dropwise, add nitric acid to adjust the pH value to 3, add 1.5ml glycerin, stir vigorously for 2h, and after aging for 36h, vacuum desorb The sol with a viscosity of 12.00mPa·s was obtained by soaking treatment; a film was coated on a silicon carbide substrate at a dipping-pulling speed of 0.5mm / s;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com