Method for preparing ferroelectric single crystal lead indium niobate-lead titanate

A technology of lead indium niobate and ferroelectric single crystal, applied in the field of crystal technology and functional materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

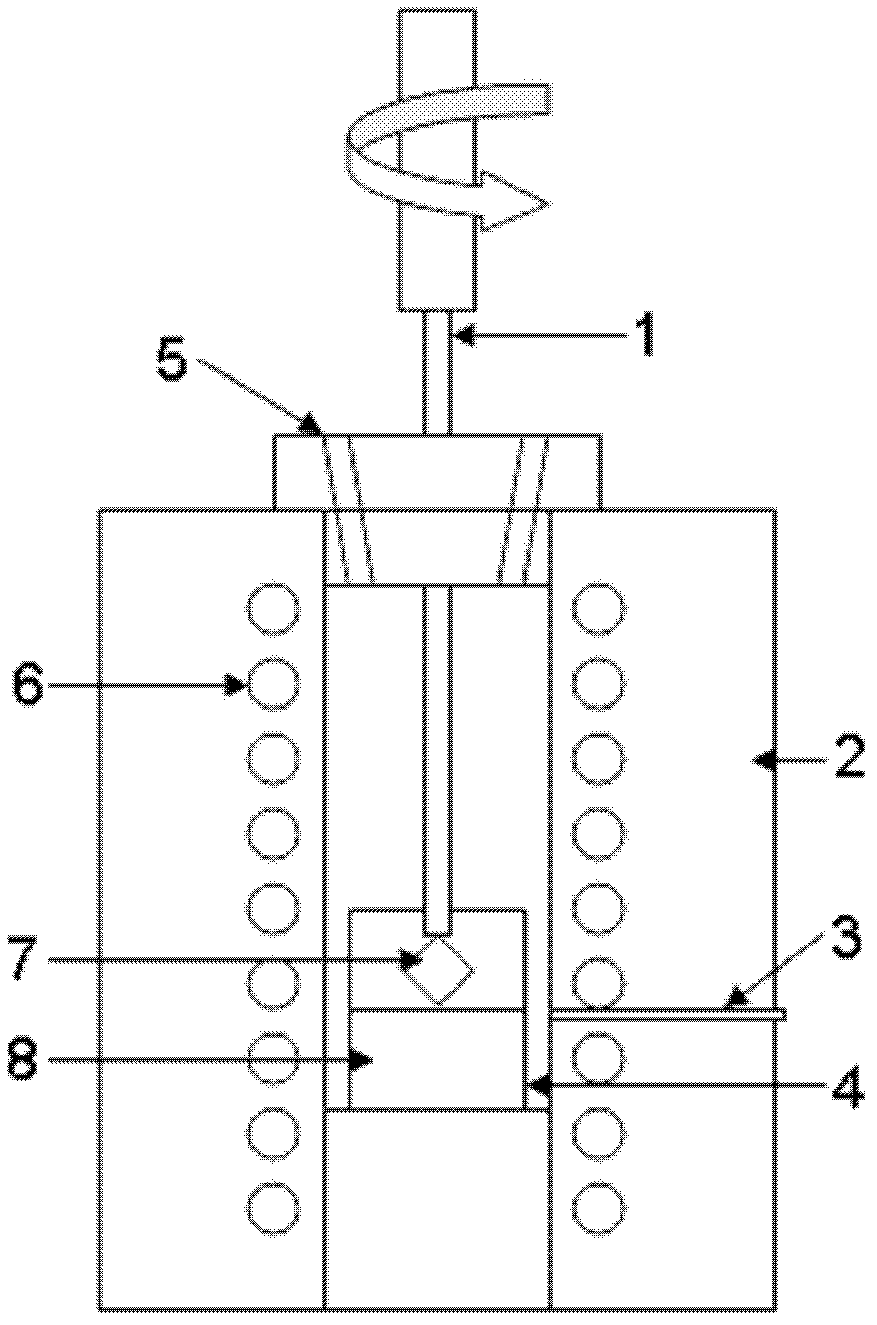

[0028] The top seed method is used to grow PIN-PT ferroelectric single crystal, and the growth furnace device is as follows figure 1 shown.

[0029] The initial raw material PbO or Pb 3 o 4 ,, In 2 o 3 、TiO 2 , Nb 2 o 5 , co-solvent using PbO or Pb 3 o 4 and H 3 BO 3 or B 2 o 3 Composite co-solvent, weighed according to the proportion, mixed and ground. Put the uniformly mixed powder into a platinum crucible, and place the platinum crucible in a crystal growth furnace to form the material. Heat the prepared material above the supersaturation temperature, keep the temperature for a certain period of time, and use the seed crystal to find the growth point for growth; grow at about 850-1200 °C, the seed crystal rod rotates during the growth process, and the crystal rotation rate is less than 50rpm, depending on the growth status Adjust forward and reverse. During the growth process, the temperature is properly cooled, and the cooling rate is less than 10°C / day; whe...

Embodiment 2

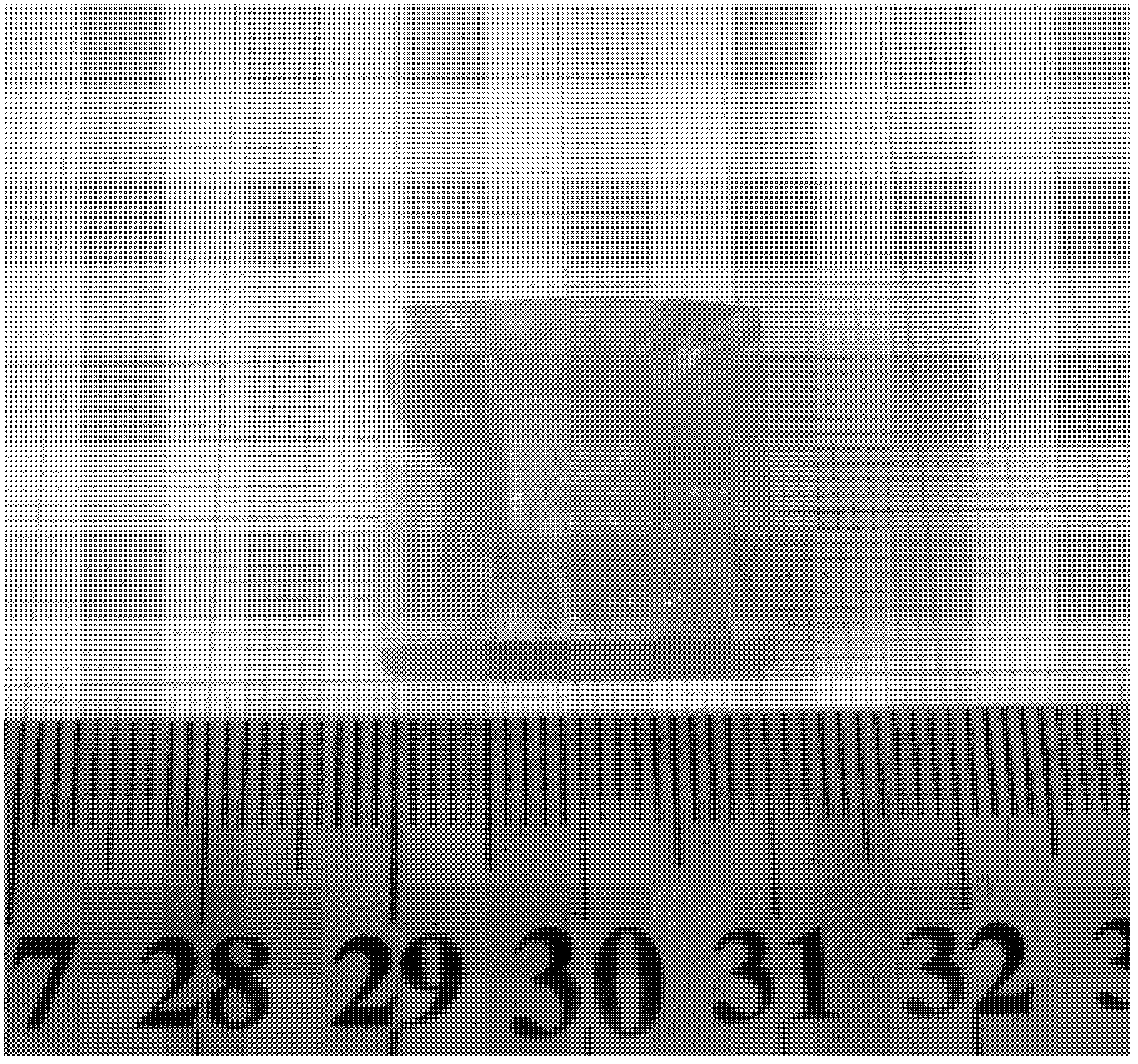

[0031] With the PIN-PT growth ferroelectric crystal material in embodiment 1 ( figure 2 Shown) for structural and performance testing, preferably component 0.655PIN-0.345PT for structural and performance testing.

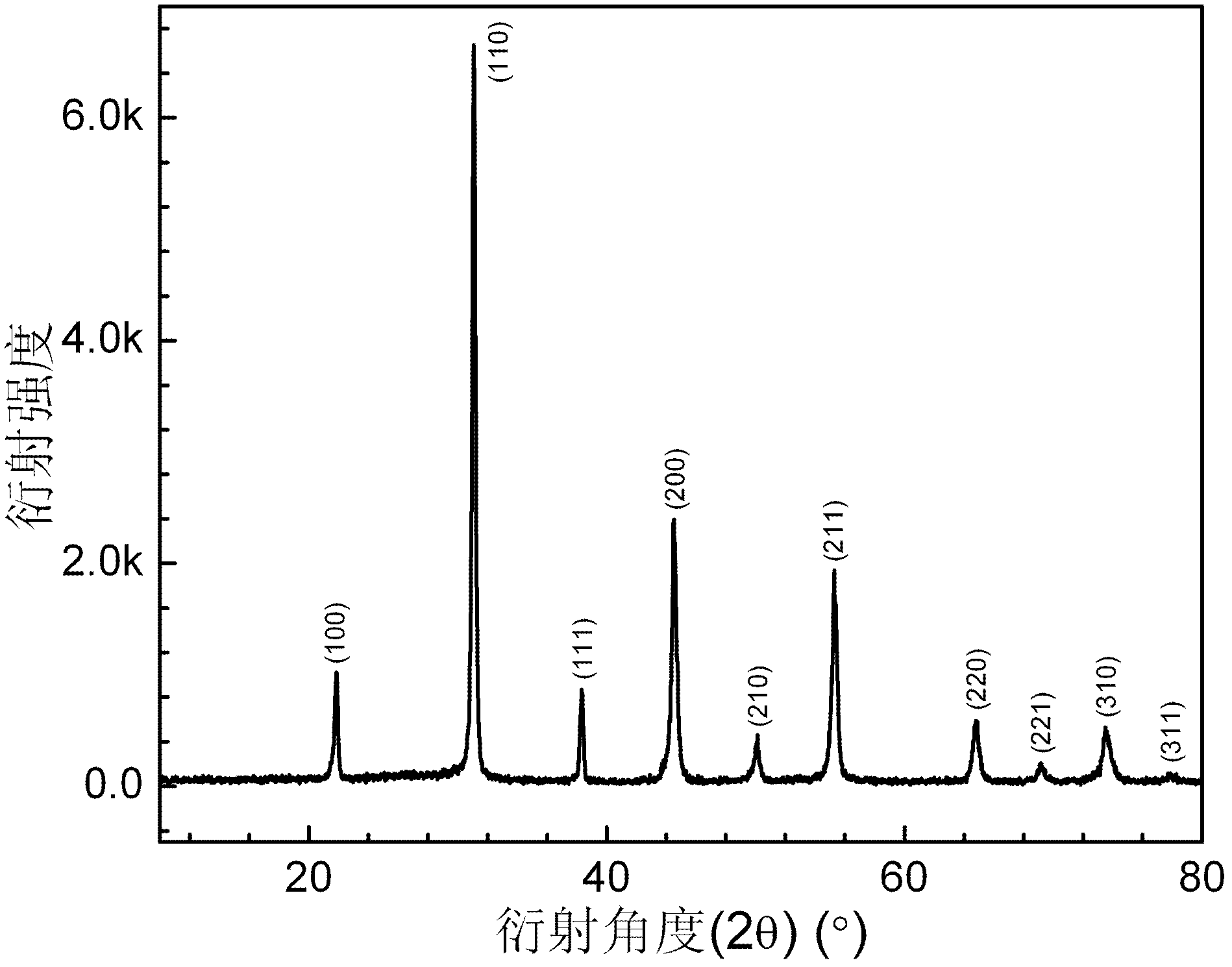

[0032] a) Cut the crystal into a small piece and grind it into powder for powder diffraction. Show that the room temperature 0.655PIN-0.345PT ferroelectric crystal is a trigonal perovskite structure ( image 3 shown).

[0033] b) Cut the obtained ferroelectric crystal material into a small slice according to the (001) direction, and then smooth both sides of the slice with different sandpapers. Coat silver electrodes on both sides that are sanded smooth. Measure the dielectric temperature spectrum of 0.655PIN-0.345PT ferroelectric crystal, the temperature is from 0℃ to 350℃. Dielectric thermogram showing the Curie temperature T of the obtained ferroelectric crystal material C is 290°C; the trigonal-tetragonal phase transition temperature T is obtained from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com