Aluminum oxide/alumina titanate ceramica composite material and preparation thereof

A technology of ceramic composite material and aluminum titanate, which is applied in the field of ceramic composite material and its preparation, can solve the problems of complex preparation process, easy decomposition of aluminum titanate and high sintering temperature, and achieves simple preparation process, uniform structure and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

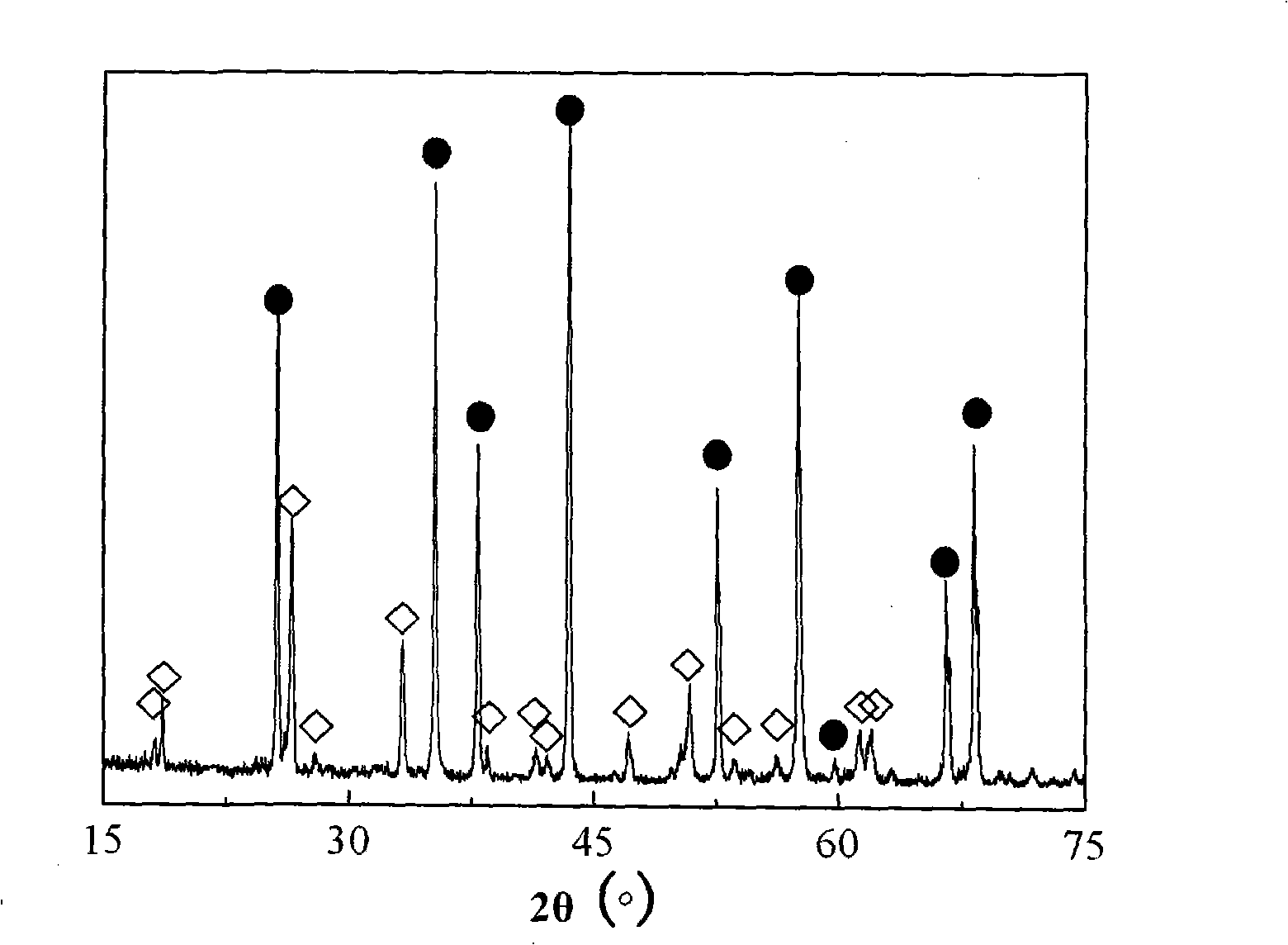

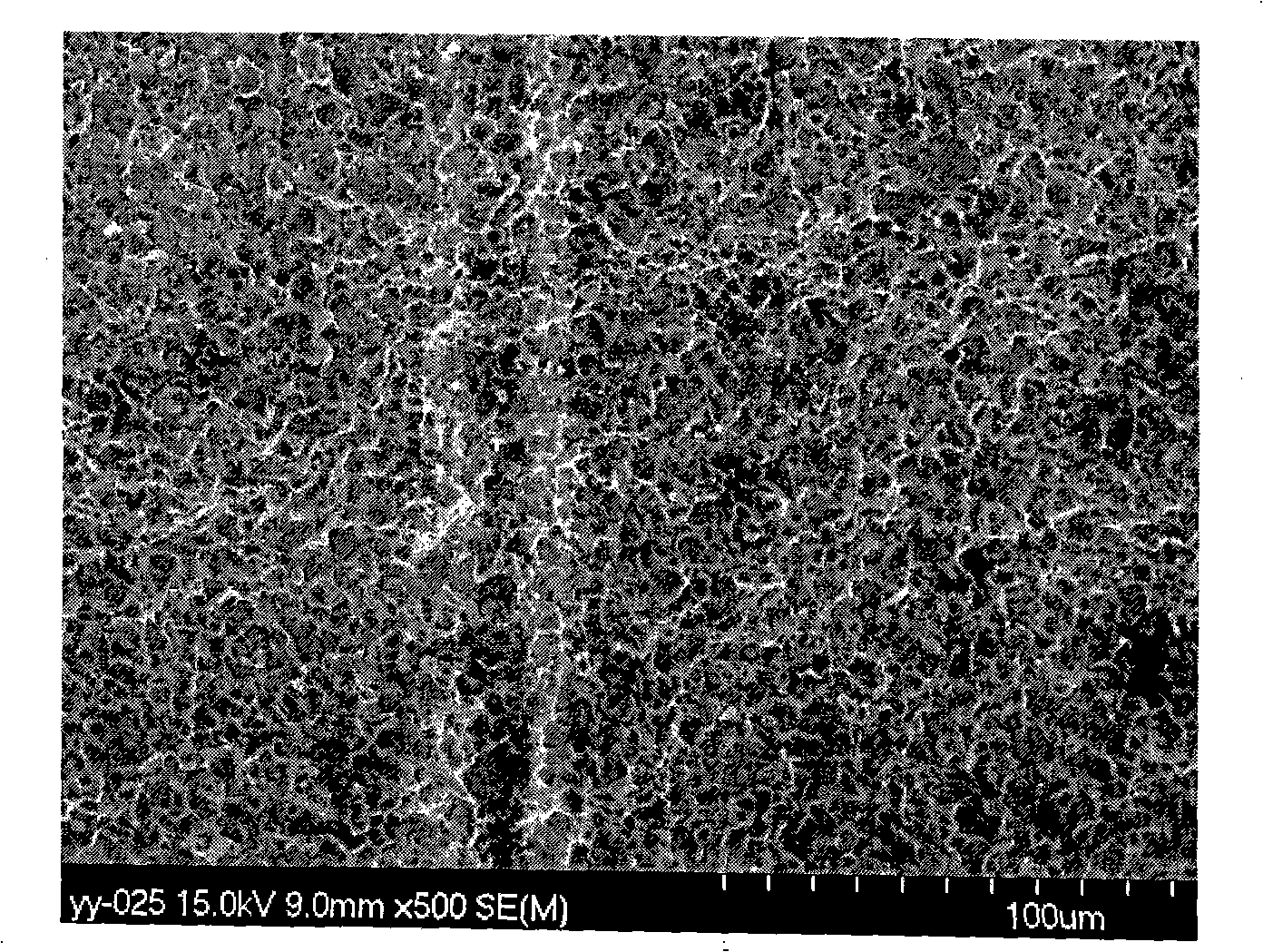

[0010] Specific Embodiment 1: In this embodiment, the alumina / aluminum titanate ceramic composite material is made of 1 part of mixed powder, 0.4-1 part of deionized water and 0.01-0.015 part of binder according to the ratio of parts by mass; the mixed powder The body is composed of 50% to 99% of nano-alumina and 1% to 50% of nano-titanium oxide by mass percentage; the binder is polyvinyl alcohol, polyethylene, polypropylene, polystyrene, methyl cellulose, carboxy Methylcellulose, polyoxyethylene or hydroxyethylcellulose.

specific Embodiment approach 2

[0011] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the alumina / aluminum titanate ceramic composite material is made of 1 part of mixed powder, 0.7 part of deionized water and 0.012 part of binder according to the ratio of parts by mass. to make. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mixed powder is composed of 60%-97% nano-alumina and 3%-40% nano-titanium oxide by mass percentage. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com