Lead tin niobate-bismuth scandate-lead titanate ternary system high temperature piezoceramic material and preparation method thereof

A lead niobate stannate and high-temperature piezoelectric technology, which is applied in the field of high-temperature piezoelectric ceramic materials, can solve the problems of not investing in large-scale industrial production, expensive Sc elements, and reduced piezoelectric performance, so as to achieve convenient operation and excellent piezoelectric performance. Electrical performance and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

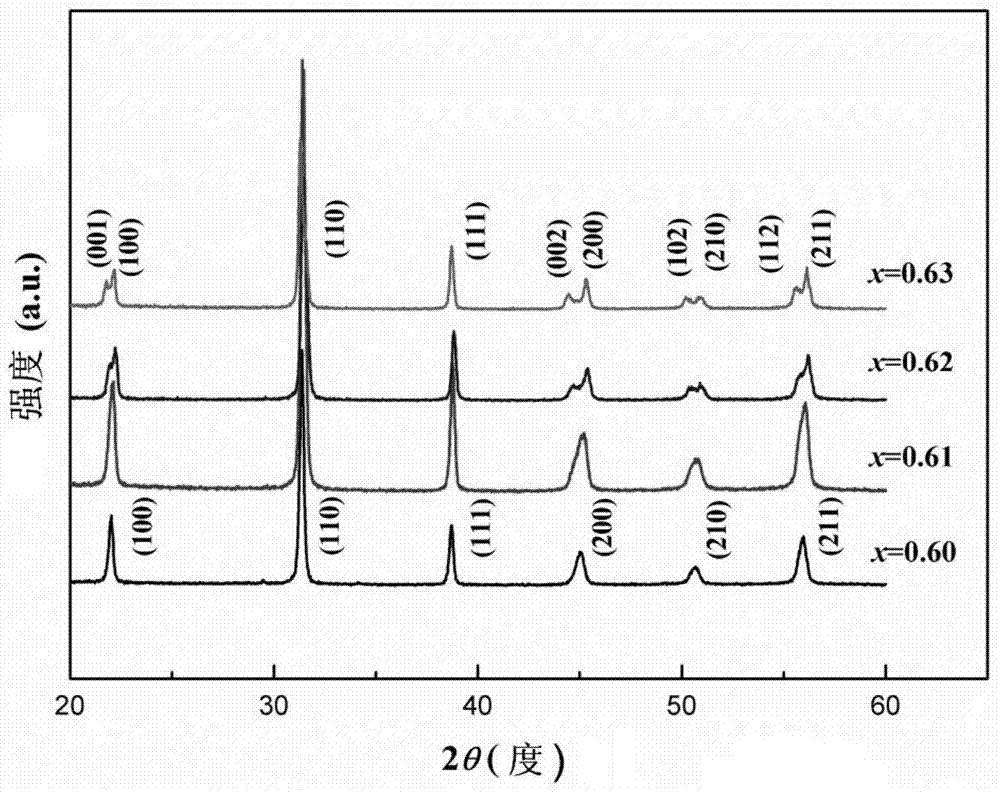

[0037] This embodiment provides a lead niobate stannate-bismuth scandate-lead titanate ternary high-temperature piezoelectric ceramic material, the composition of which is represented by the following formula:

[0038] 0.05Pb(Sn 1 / 3 Nb 2 / 3 )O 3 -0.35BiScO 3 -0.60PbTiO 3

[0039] where x takes a value of 0.60.

[0040] In this embodiment, the preparation method of lead niobate stannate-bismuth scandate-lead titanate ternary high-temperature piezoelectric ceramic material is as follows:

[0041] 1) Sc with an analytical purity of 99.9% 2 o 3 、 Bi 2 o 3 , Nb 2 o 5 , PbO, TiO 2 and SnO 2 As a raw material, according to the general formula 0.05Pb(Sn 1 / 3 Nb 2 / 3 )O 3 -0.35BiScO 3 -0.60PbTiO 3 The stoichiometric ratio for batching. Put the prepared raw materials into a ball mill tank, add absolute ethanol accounting for 60-80% of the total weight of the raw materials, and mill for 8-12 hours at a ball milling rate of 200-300r / min;

[0042] 2) Place the ball-milled mi...

Embodiment 2

[0048] This embodiment provides a lead niobate stannate-bismuth scandate-lead titanate ternary high-temperature piezoelectric ceramic material, the composition of which is represented by the following formula:

[0049] 0.05Pb(Sn 1 / 3 Nb 2 / 3 )O 3 -0.34 BiScO 3 -0.61PbTiO 3

[0050] Where x takes the value of 0.61. The preparation method of the high temperature piezoelectric ceramic material with this composition is the same as that of Example 1.

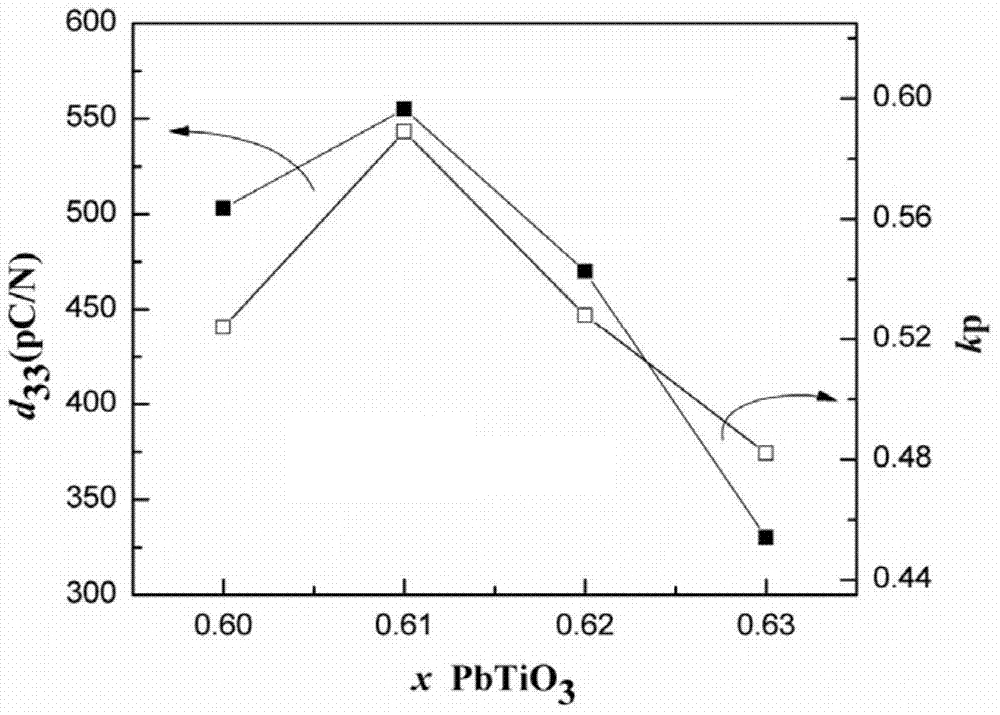

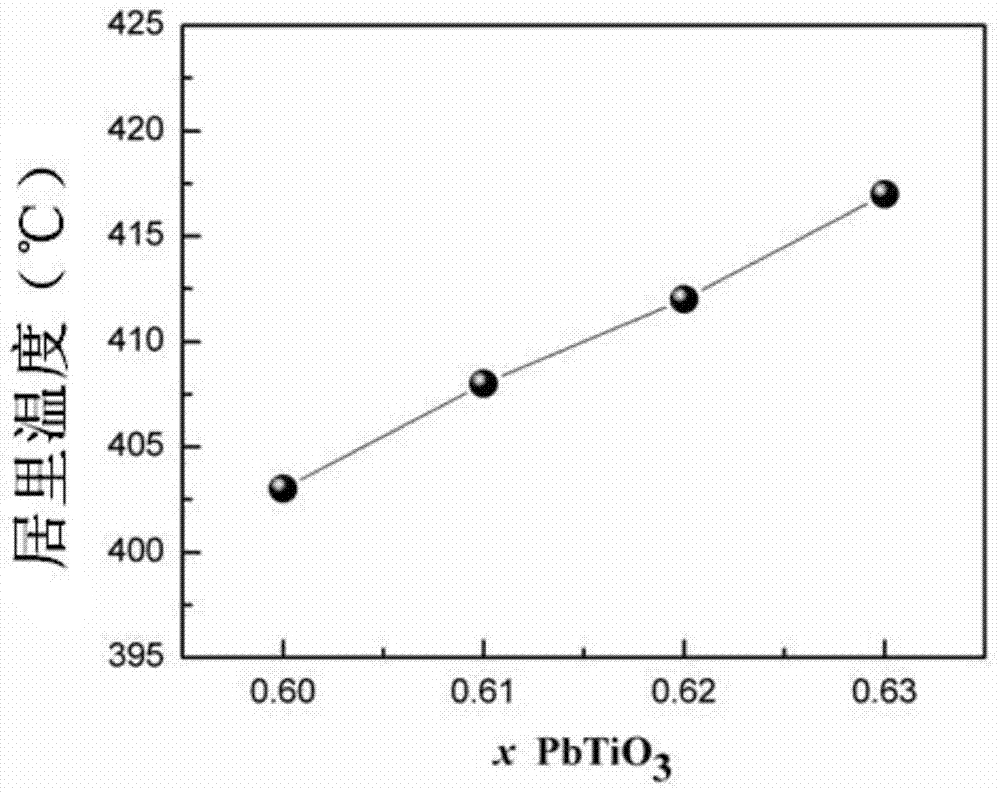

[0051] It is known through testing that the performance parameters of the high-temperature piezoelectric ceramic material prepared in this embodiment are as follows: d 33 =555pC / N,k p =0.589, tanδ=0.065, T c =408°C.

Embodiment 3

[0053] This embodiment provides a lead niobate stannate-bismuth scandate-lead titanate ternary high-temperature piezoelectric ceramic material, the composition of which is represented by the following formula:

[0054] 0.05Pb(Sn 1 / 3 Nb 2 / 3 )O 3 -0.33 BiScO 3 -0.62PbTiO 3

[0055] Where x takes the value of 0.62. The preparation method of the high temperature piezoelectric ceramic material with this composition is the same as that of Example 1.

[0056] It is known through testing that the performance parameters of the high-temperature piezoelectric ceramic material prepared in this embodiment are as follows: d 33 =470pC / N,k p =0.528, tanδ=0.039, T c =412°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com