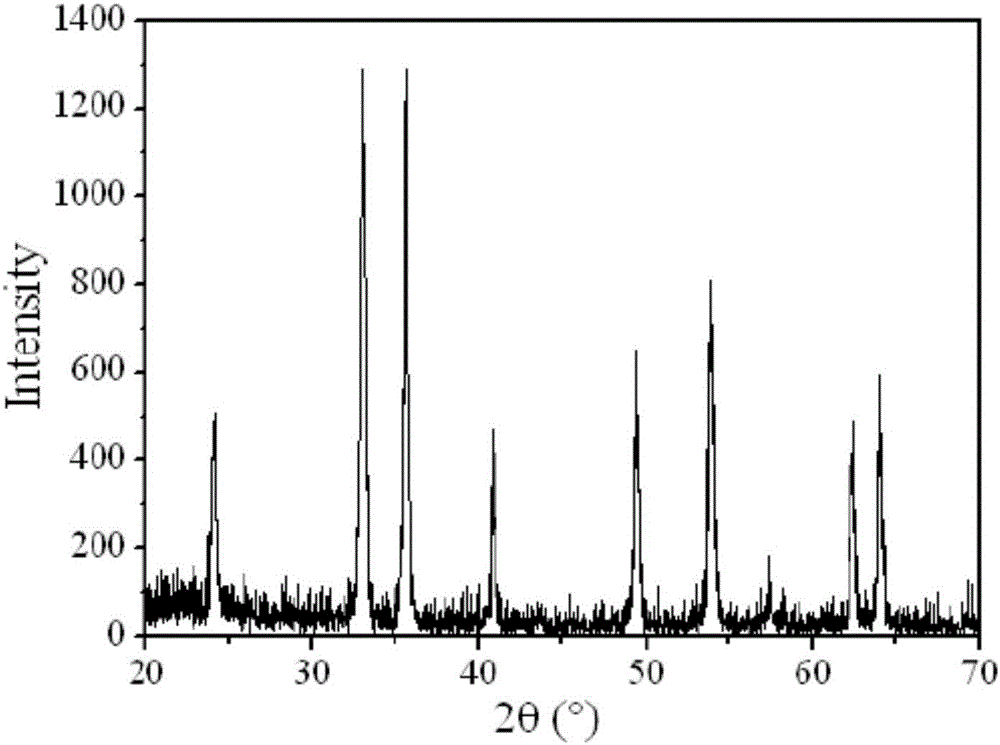

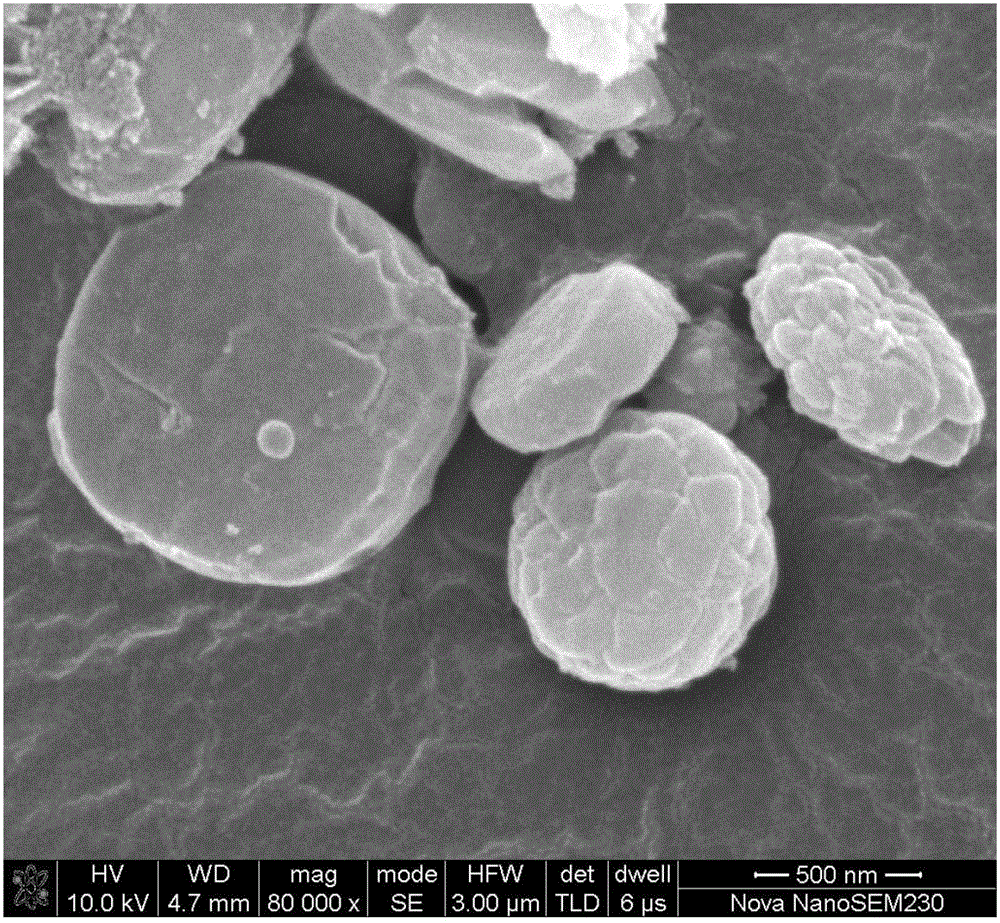

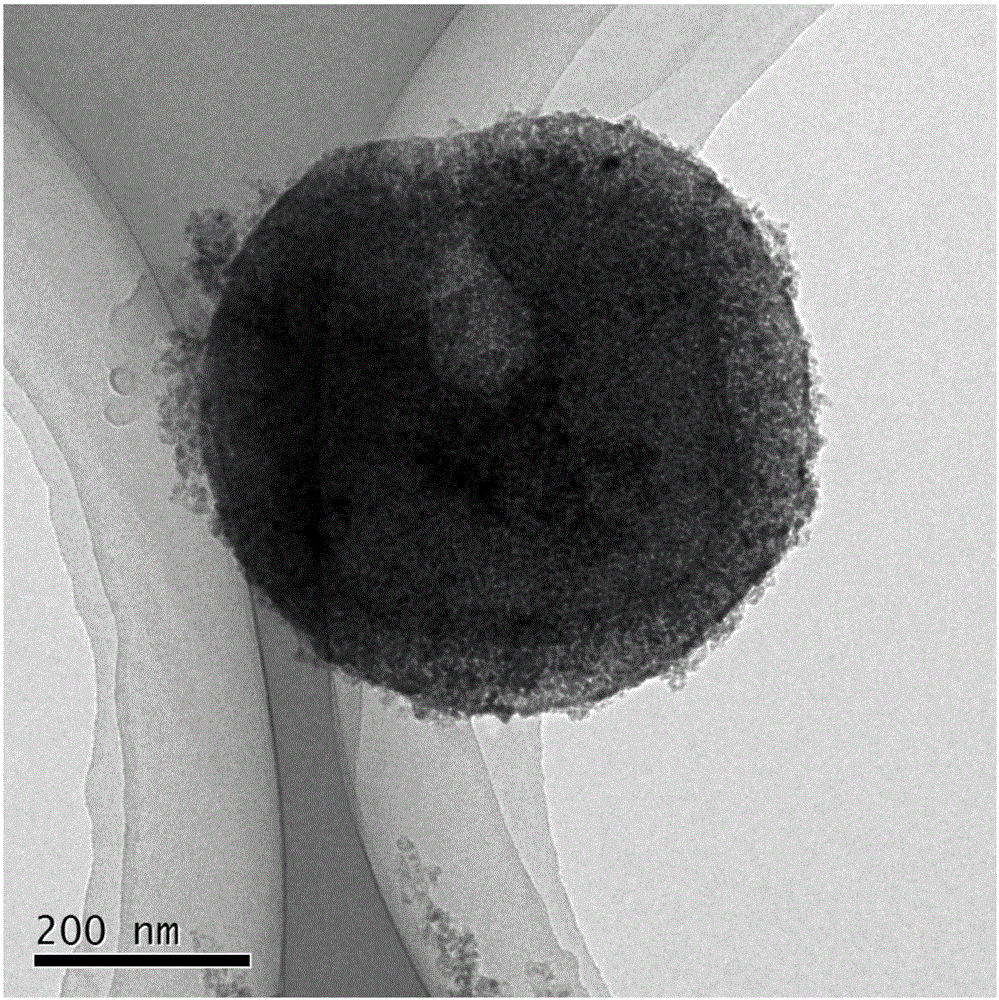

Sodium-ion battery nickel titanate cathode material and preparation method thereof

A sodium ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of no great advantage in cycle performance and rate performance, no fixed shape, crystal impurity, etc., to achieve improved cycle performance Stability and rate capability, low cost, effect of increasing wetted contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]First weigh 1.7g tetrabutyl titanate and 1.45g nickel nitrate hexahydrate, fully dissolve them in a mixed solution composed of 200ml N'N-dimethylformamide and 200ml methanol, then weigh 9.96g 1,4 - Terephthalic acid was slowly added to the above solution under magnetic stirring conditions, and after stirring evenly, the resulting mixed solution was transferred to a polytetrafluoroethylene reactor, and a solvothermal reaction was carried out at 160 ° C. After 18 hours of reaction, the obtained precipitate was The material was repeatedly washed with methanol and N'N-dimethylformamide, and dried to obtain the Ti-Ni bimetallic MOFs precursor.

[0046] Weigh an appropriate amount of Ti-Ni bimetallic MOFs precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Oxygen was introduced to raise the temperature of the tube furnace to 150°C, and kept at this temperature for 1.5h; then, the tube furnace was continued to be heated to 700°C and fully ox...

Embodiment 2

[0053] First weigh 1.7g of tetrabutyl titanate and 1.45g of nickel nitrate hexahydrate and dissolve them in 400mL of N'N-dimethylformamide, then weigh 6.64g of 1,4-terephthalic acid in a magnetic Slowly added to the above solution under stirring conditions, after stirring evenly, the resulting mixed solution was transferred to a polytetrafluoroethylene reactor, and a solvothermal reaction was carried out at 160 ° C. After 14 hours of reaction, the obtained precipitate was subjected to methanol and N'N - Dimethylformamide is repeatedly washed and dried to obtain the Ti-Ni bimetallic MOFs precursor.

[0054] Weigh an appropriate amount of Ti-Ni bimetallic MOFs precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Oxygen was introduced to raise the temperature of the tube furnace to 180°C, and kept at this temperature for 1.5h; then, the tube furnace was continued to be heated to 600°C and fully oxidized for 6h. Finally, the obtained oxidation ...

Embodiment 3

[0058] First, weigh 1.7g of tetrabutyl titanate and 1.45g of nickel nitrate hexahydrate to fully dissolve them in 400mL of methanol solution, then weigh 9.96g of 1,4-terephthalic acid and slowly add them to the above solution, after stirring evenly, the resulting mixed solution was transferred to a polytetrafluoroethylene reactor, and a solvothermal reaction was carried out at 180 ° C. After 18 hours of reaction, the obtained precipitate was repeatedly subjected to methanol and N'N-dimethylformamide. After washing and drying, the precursor of Ti-Ni bimetallic MOFs can be obtained.

[0059] Weigh an appropriate amount of Ti-Ni bimetallic MOFs precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. The temperature of the tube furnace was raised to 180°C by feeding oxygen, and kept at this temperature for 1h; then, the temperature of the tube furnace was continued to be raised to 700°C and fully oxidized for 4h. Finally, the obtained oxidation pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com