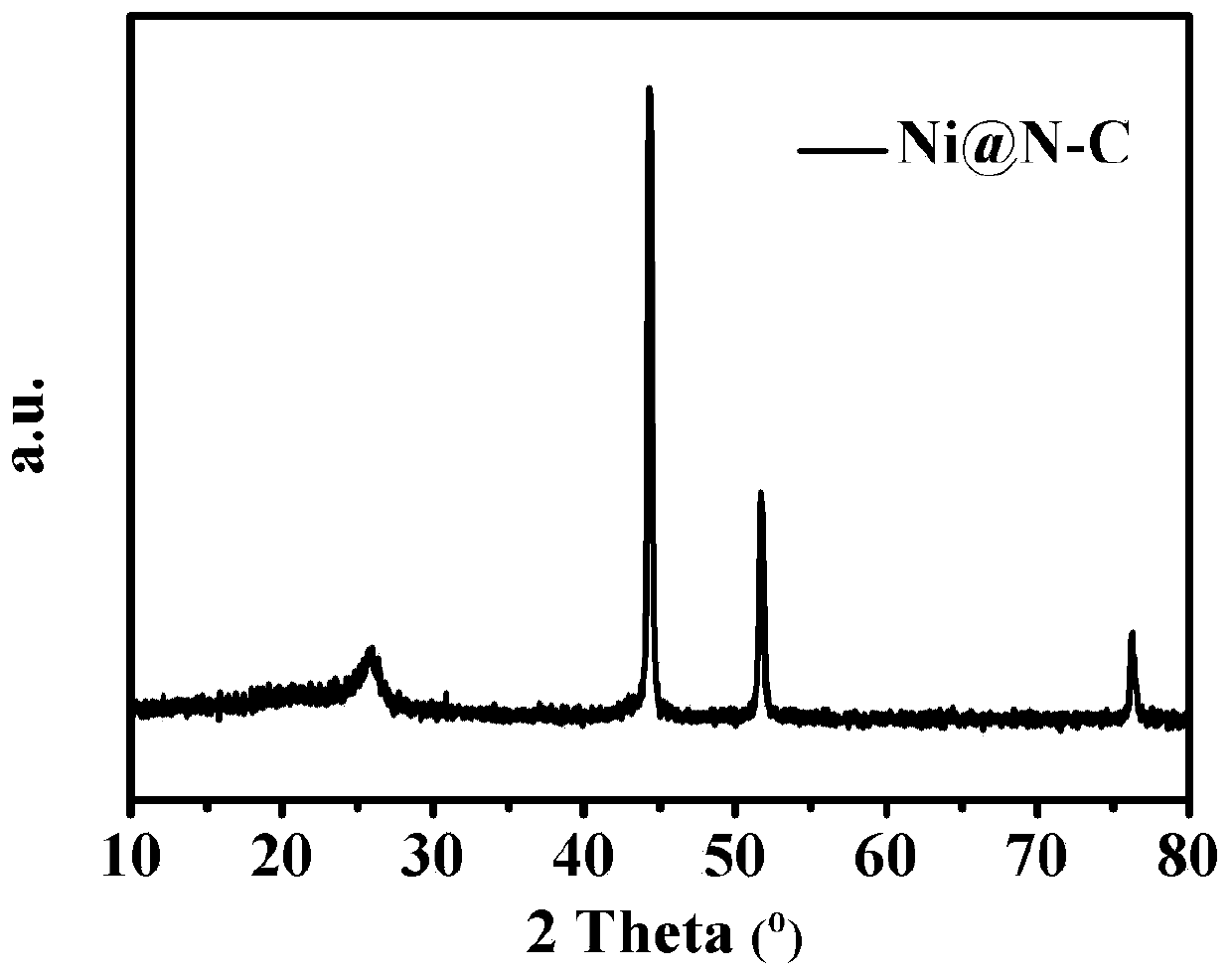

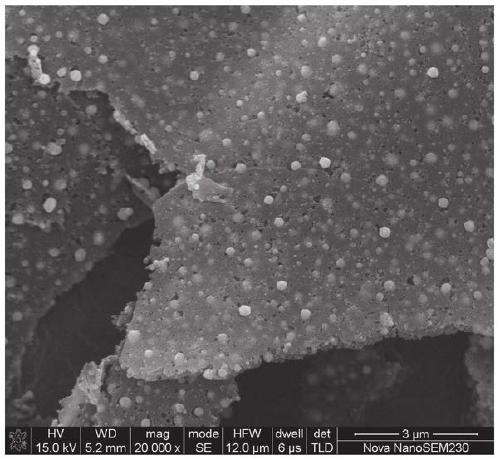

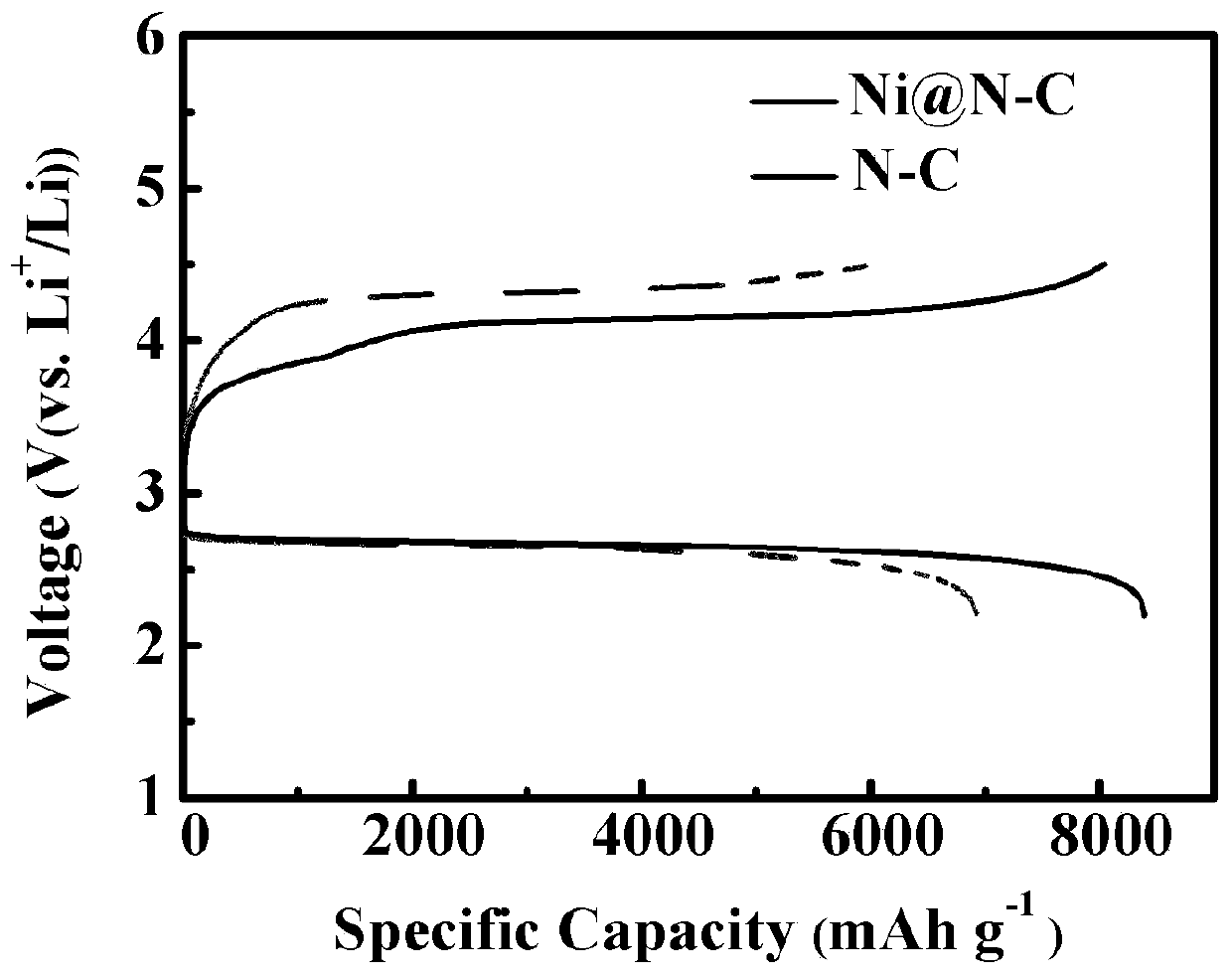

A kind of ni@n-c composite positive electrode material, preparation method and application in lithium-air battery

A composite positive electrode material, lithium-air battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effect of simple and reliable operation, environmental friendliness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] First, weigh 2.0 g of chitosan, add them into a beaker containing 30 mL of water, and stir to form a suspension; 1.0 g of nickel acetate is dissolved in 10 mL of water to form a nickel acetate solution. Measure a certain amount of glacial acetic acid to form a 5vol% acetic acid solution, and slowly add the acetic acid solution dropwise to the chitosan suspension under stirring conditions. With the addition of acetic acid, the suspension gradually becomes transparent and forms Viscous glue; nickel acetate solution was added dropwise to the above transparent glue to form a green clear glue (mixed solution; pH 4.5; chitosan concentration 20mg / mL), freeze-dried for 24 hours to obtain the precursor.

[0063] Weigh an appropriate amount of precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Introduce argon gas, raise the temperature of the tube furnace to 1000°C at a heating rate of 2°C / min, and heat-preserve for 3 hours to obtain the Ni@N...

Embodiment 2

[0070] First, weigh 2.0g of chitosan respectively, add them into a beaker containing 30mL of water, and stir to form a suspension; 0.8g of nickel acetate is dissolved in 10mL of water to form a nickel acetate solution. Measure a certain amount of glacial acetic acid to form a 10vol% acetic acid solution, and slowly add the acetic acid solution dropwise to the suspension of chitosan under stirring conditions. With the addition of acetic acid, the suspension gradually becomes transparent and forms Viscous glue; nickel acetate solution was added dropwise to the above transparent glue to form a green clear glue (mixed solution; pH 4.5; chitosan concentration 18mg / mL), freeze-dried for 18 hours to obtain the precursor.

[0071] Weigh an appropriate amount of precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Introduce argon gas, raise the temperature of the tube furnace to 900°C at a rate of 3°C / min, and heat-treat for 3 hours to obtain the Ni@...

Embodiment 3

[0076] First, weigh 2.0 g of chitosan, add them into a beaker containing 30 mL of water, and stir to form a suspension; 0.5 g of nickel acetate is dissolved in 10 mL of water to form a nickel acetate solution. Measure a certain amount of glacial acetic acid to form a 5vol% acetic acid solution, and slowly add the acetic acid solution dropwise to the chitosan suspension under stirring conditions. With the addition of acetic acid, the suspension gradually becomes transparent and forms Viscous glue; nickel acetate solution was added dropwise to the above transparent glue to form a green clear glue (mixed solution; pH 4.5; chitosan concentration 15mg / mL), freeze-dried for 12 hours to obtain the precursor.

[0077] Weigh an appropriate amount of precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Introduce argon gas, raise the temperature of the tube furnace to 800°C at a heating rate of 3°C / min, and heat-preserve for 6 hours to obtain the Ni@N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com