A molybdenum carbide/carbon composite material with core-shell structure and its preparation method and application in lithium-air battery

A technology of carbon composite materials and core-shell structure, which is applied in the direction of fuel cell half-cells and secondary battery-type half-cells, structural parts, battery electrodes, etc. Harsh synthesis conditions, difficult to achieve industrial production and other issues, to achieve the effect of improving cycle stability, increasing wet contact area, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

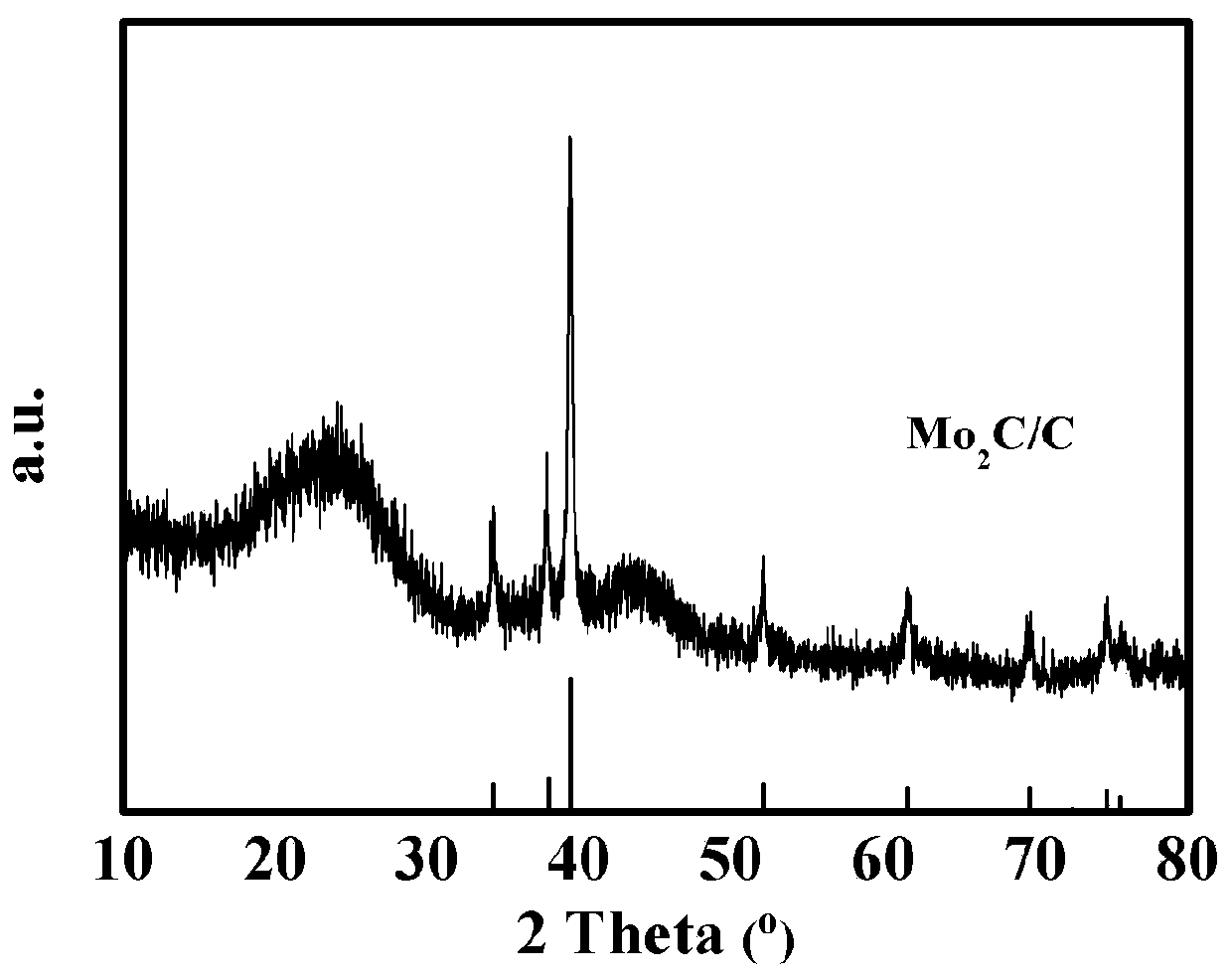

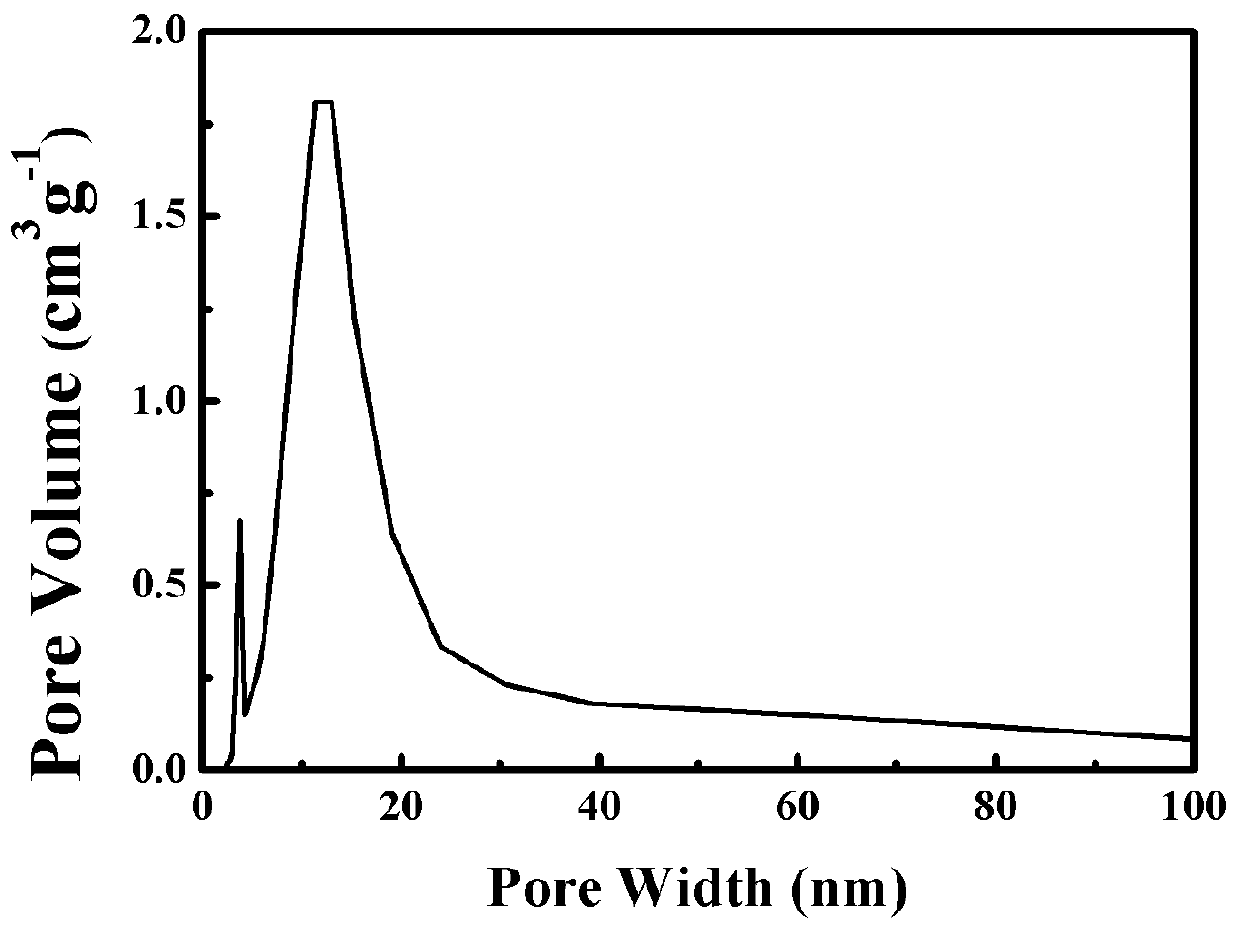

[0045] First weigh 3.85g resorcinol and add it into a beaker, then measure 5mL, add 37% formaldehyde solution dropwise into the beaker, and stir to form a phenolic resin solution. Weigh 1.236g of ammonium molybdate and dissolve it in 60mL of water to form ammonium molybdate solution and add it to the above phenolic resin solution. After stirring evenly, transfer the resulting mixed suspension to a polytetrafluoroethylene solvothermal reaction kettle at 160°C. Solvothermal reaction, after 18 hours of reaction, the resulting precipitate was repeatedly washed with water and ethanol, and dried to obtain a spherical precursor.

[0046] Weigh an appropriate amount of spherical precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Introduce argon gas, heat the tube furnace to 850°C for 6 hours, and obtain the molybdenum carbide / carbon composite material.

[0047] The lithium-air battery molybdenum carbide / carbon composite material prepared in this ...

Embodiment 2

[0054] First weigh 3.85g of resorcinol and add it into a beaker, then measure 6mL, add 37% formaldehyde solution dropwise into the beaker, and stir to form a phenolic resin solution. Weigh 1.236g of ammonium molybdate and dissolve it in 60mL of water to form ammonium molybdate solution and add it to the above phenolic resin solution. After stirring evenly, transfer the resulting mixed suspension to a polytetrafluoroethylene solvothermal reaction kettle and carry out at 180°C. Solvothermal reaction, after 14 hours of reaction, the resulting precipitate was repeatedly washed with water and ethanol, and dried to obtain a spherical precursor.

[0055] Weigh an appropriate amount of spherical precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Introduce argon gas, heat the tube furnace to 800°C for 8 hours, and obtain the molybdenum carbide / carbon composite material.

[0056] The molybdenum carbide / carbon composite material prepared by the meth...

Embodiment 3

[0059] First weigh 3.85g of resorcinol and add it into a beaker, then measure 4mL, add 37% formaldehyde solution dropwise into the beaker, and stir to form a phenolic resin solution. Weigh 1.854g of ammonium molybdate and dissolve it in 60mL of water to form ammonium molybdate solution and add it to the above phenolic resin solution. After stirring evenly, transfer the resulting mixed suspension to a polytetrafluoroethylene solvothermal reaction kettle and carry out at 180°C. Solvothermal reaction, after 20 hours of reaction, the resulting precipitate was repeatedly washed with water and ethanol, and dried to obtain a spherical precursor.

[0060] Weigh an appropriate amount of spherical precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Introduce argon gas, heat the tube furnace to 850°C for 8 hours, and obtain the molybdenum carbide / carbon composite material.

[0061] The molybdenum carbide / carbon composite material prepared by the meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com