A kind of vc/graphene composite material and its preparation method and application in lithium air battery

A composite material and graphene technology, which is applied in the direction of fuel cell half-cells and secondary battery-type half-cells, battery electrodes, circuits, etc., can solve the problems of few related reports and achieve good electrical conductivity and high catalytic activity , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

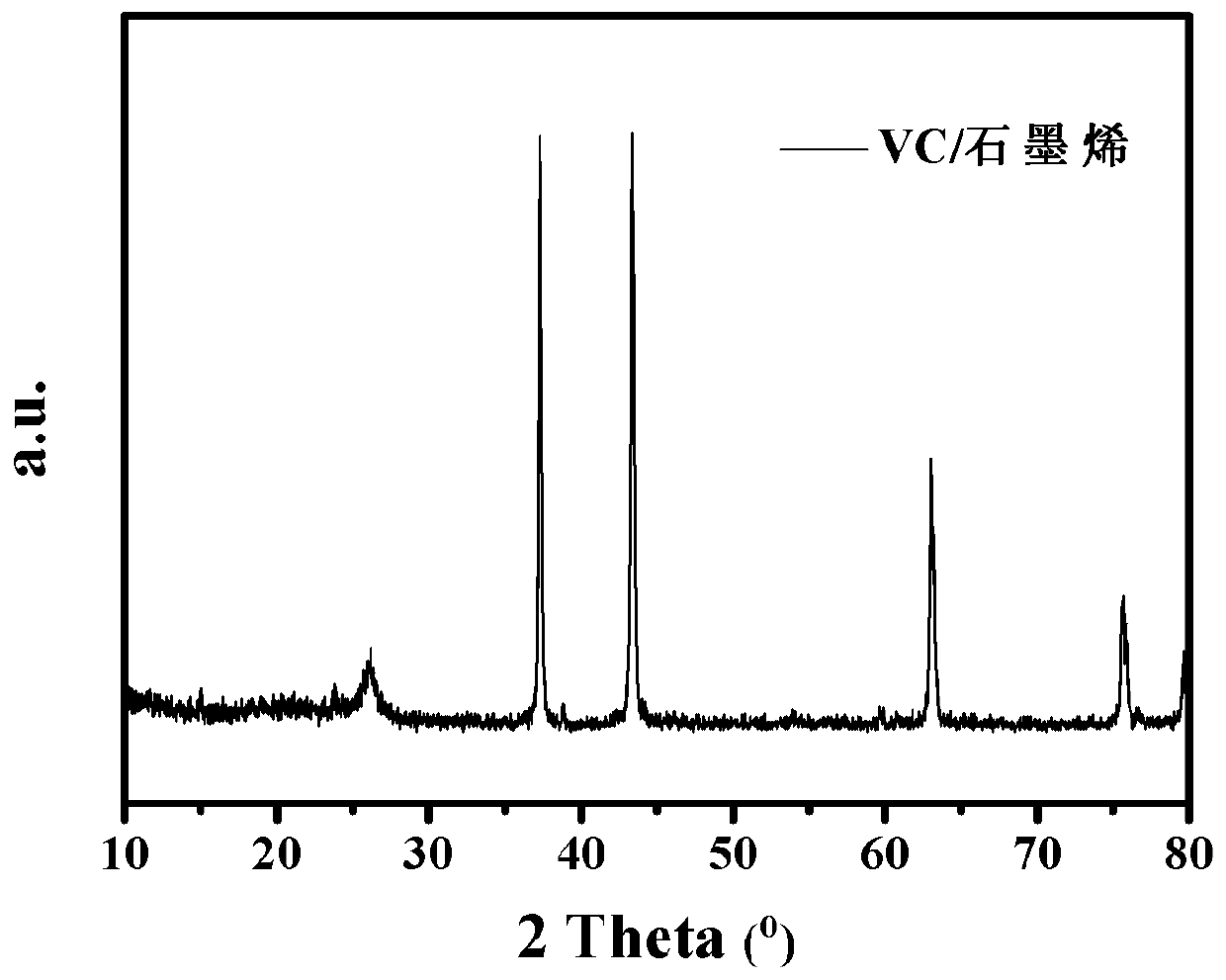

[0043]First, 0.8 g of vanadyl acetylacetonate and 0.3 g of polyvinylpyrrolidone were weighed, added into a beaker containing 30 mL of ethanol, and stirred to form a transparent solution. Weigh 60 mg of graphene and dissolve it in 10 mL of water to form a graphene solution, add it to the above solution, and after stirring evenly, transfer the resulting mixed solution to a polytetrafluoroethylene solvothermal reaction kettle, and carry out solvothermal reaction at 160 °C. After 24 hours, the obtained precipitate was repeatedly washed with water and ethanol, and dried to obtain the precursor.

[0044] Weigh an appropriate amount of precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Introduce argon gas, heat the tube furnace to 1000°C for 3 hours, and obtain the VC / graphene composite material.

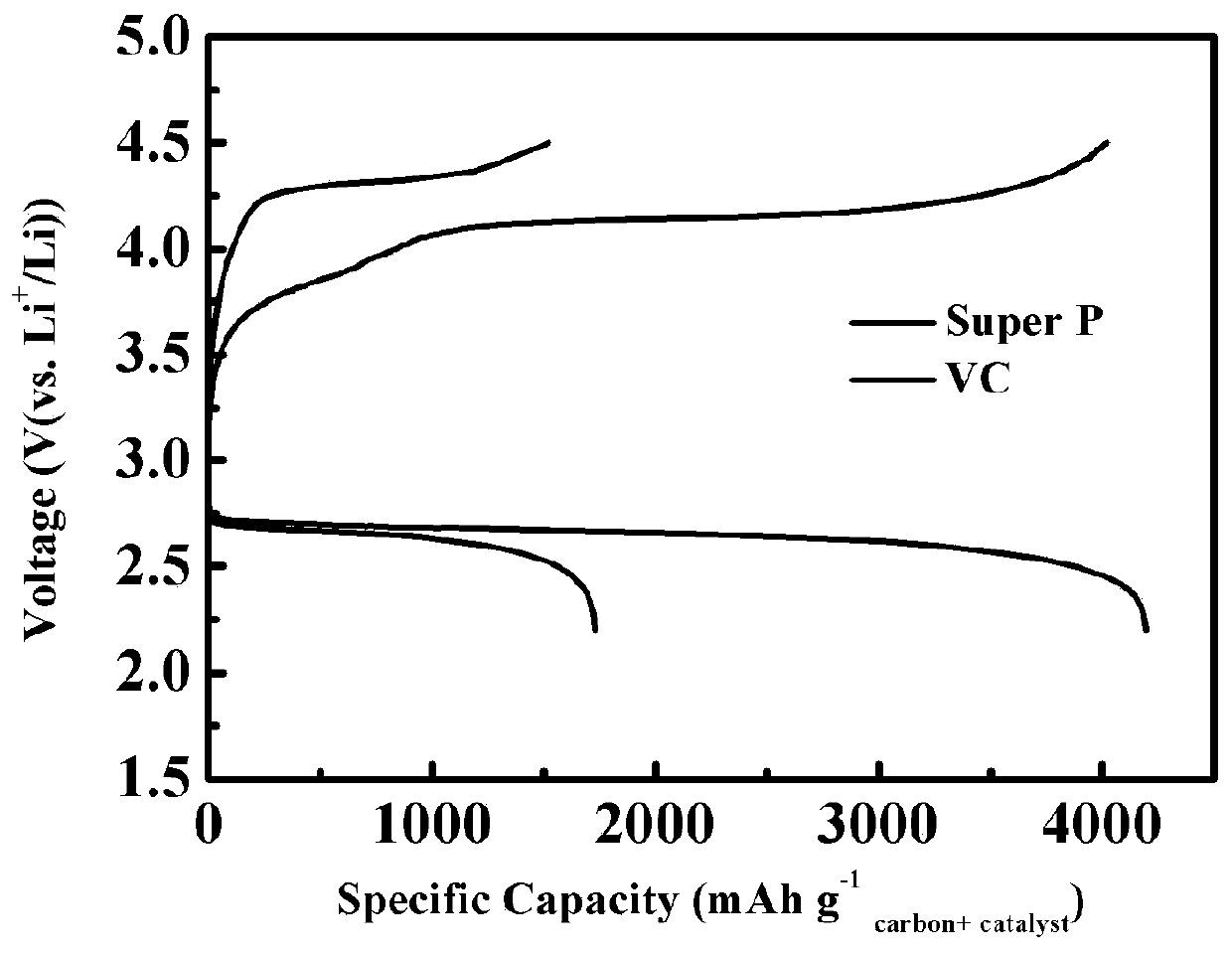

[0045] The lithium-air battery VC / graphene composite material prepared in this example is assembled into a button battery with lithium, and its mater...

Embodiment 2

[0051] First, weigh 0.8 g of vanadyl acetylacetonate and 0.2 g of polyvinylpyrrolidone, add them into a beaker containing 30 mL of ethanol, and stir to form a transparent solution. Weigh 60 mg of graphene and dissolve it in 10 mL of water to form a graphene solution, add it to the above solution, and after stirring evenly, transfer the resulting mixed solution to a polytetrafluoroethylene solvothermal reaction kettle, and carry out solvothermal reaction at 180 °C. After 18 hours, the obtained precipitate was repeatedly washed with water and ethanol, and dried to obtain the precursor.

[0052] Weigh an appropriate amount of precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Introduce argon gas, heat the tube furnace to 1000°C for 2 hours, and obtain the VC / graphene composite material.

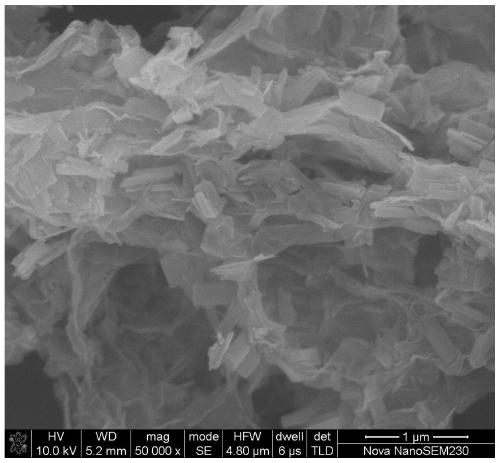

[0053] The VC / graphene composite material prepared by the method is that flake VC is uniformly distributed between graphene and on the surface, wherein the...

Embodiment 3

[0056] Firstly, 0.8 g of vanadyl acetylacetonate and 0.5 g of polyvinylpyrrolidone were weighed, added into a beaker containing 20 mL of ethanol, and stirred to form a transparent solution. Weigh 40 mg of graphene and dissolve it in 20 mL of water to form a graphene solution, add it to the above solution, stir evenly, transfer the resulting mixed solution to a polytetrafluoroethylene solvothermal reaction kettle, and carry out solvothermal reaction at 180 °C. After 12 hours, the obtained precipitate was repeatedly washed with water and ethanol, and dried to obtain the precursor.

[0057] Weigh an appropriate amount of precursor, put it into a corundum porcelain boat, and place it in a vacuum tube furnace. Introduce argon gas, heat the tube furnace to 900°C for 4 hours, and obtain the VC / graphene composite material.

[0058] The VC / graphene composite material prepared by the method is that flake VC is evenly distributed between graphene and on the surface, wherein the flake VC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com