Method for extracting metal scandium and titanium from red mud

A technology for extracting metals and red mud is applied in the field of extracting metal scandium and titanium, which can solve the problems of waste of resources and low comprehensive utilization of red mud, and achieve the effects of reducing processing costs, facilitating comprehensive utilization and high recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

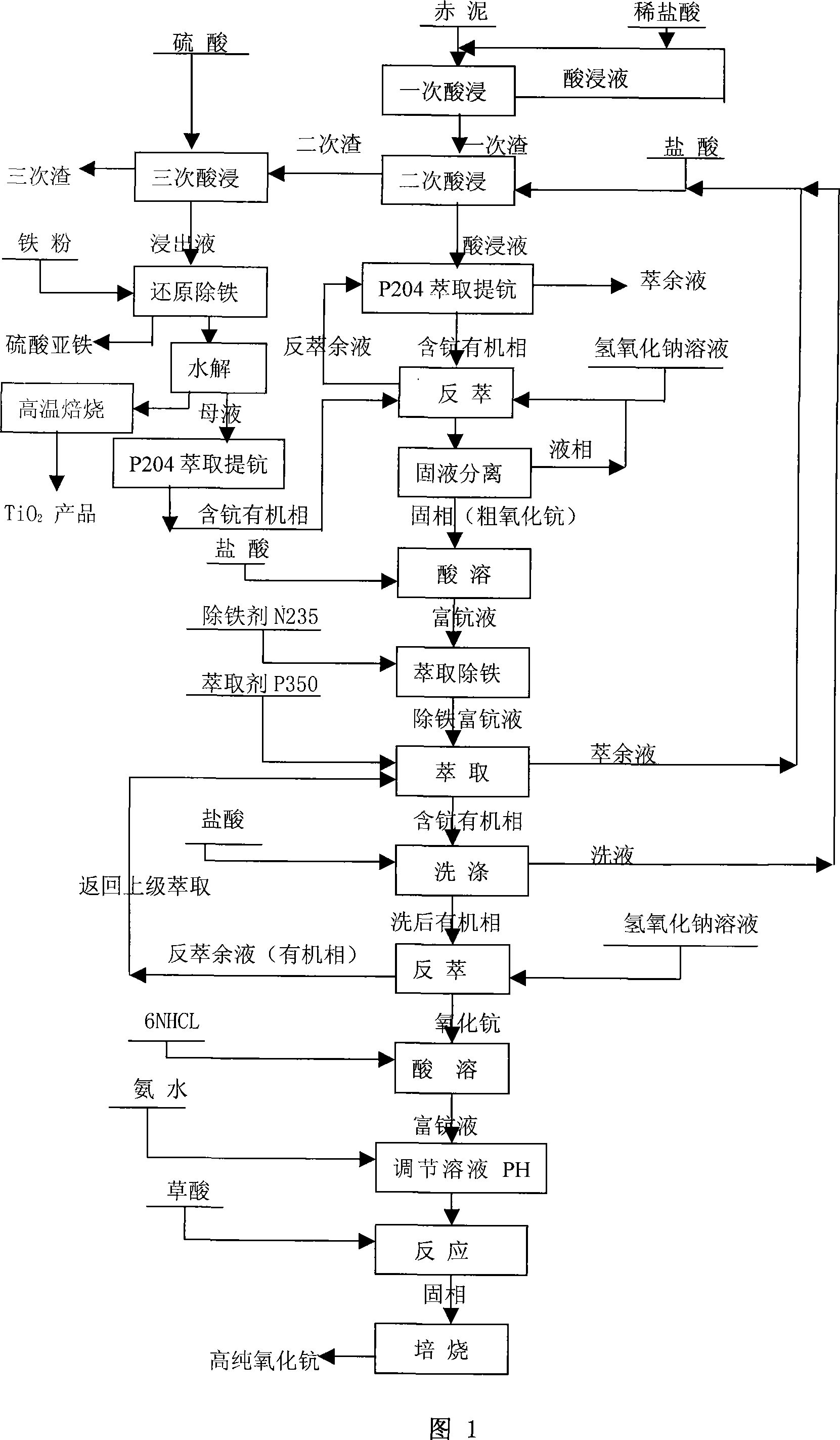

Image

Examples

Embodiment 1

[0029] Preparation of high-purity scandium oxide:

[0030] First, use 4% hydrochloric acid and rich ore red mud at a liquid-solid ratio of 5.6:1 to react at 90°C for 5 minutes and then filter. Calculate the concentrated hydrochloric acid and water needed to prepare 19% hydrochloric acid according to the moisture in the filter cake. , according to the liquid-solid ratio L / S=3:1, react with the filter cake at 98°C for 30 minutes and then filter to obtain a leach solution containing scandium 52mg / L. The extraction agent is prepared by diisooctyl phosphate (P204): kerosene at a ratio of 1:49, and the extraction agent and the scandium-containing solution are mixed and reacted at a ratio of 1:8 for 10 minutes to obtain an organic phase containing scandium. Wash the scandium-containing organic phase 2 times with 19% hydrochloric acid at a ratio of 1:1 compared to O / A, and the washing time is 5 minutes / time to remove impurities such as part of titanium and iron in the scandium-contain...

Embodiment 2

[0037] Preparation of high-purity scandium oxide:

[0038] First, use 6% hydrochloric acid and rich ore red mud at a liquid-solid ratio of 4:1 to react at 90°C for 10 minutes and then filter. Calculate the concentrated hydrochloric acid and water needed to configure 19% hydrochloric acid according to the moisture in the filter cake. According to the ratio of liquid-solid ratio L / S=2.6:1, react with the filter cake at 95°C for 50 minutes and then filter to obtain a leach solution containing scandium 59mg / L. The extraction agent is prepared by diisooctyl phosphate (P204): kerosene at a ratio of 1:24, and the extraction agent and the scandium-containing solution are mixed and reacted at a ratio of 1:10 for 10 minutes to obtain an organic phase containing scandium. Wash the scandium-containing organic phase 2 times with 18% hydrochloric acid at a ratio of 1:1 compared to O / A, and the washing time is 5 minutes / time to remove impurities such as part of titanium and iron in the scand...

Embodiment 3

[0045] Preparation of high-purity scandium oxide:

[0046] First, use 5% hydrochloric acid and rich ore red mud at a liquid-solid ratio of 6:1 to react at 80°C for 15 minutes and then filter. Calculate the concentrated hydrochloric acid and water needed to configure 19% hydrochloric acid according to the moisture in the filter cake. According to the ratio of liquid-solid ratio L / S=3.5:1, react with the filter cake at 90°C for 30 minutes and then filter to obtain a leaching solution containing scandium 45mg / L. The extraction agent is prepared by diisooctyl phosphate (P204): kerosene at a ratio of 1:49, and the extraction agent and the scandium-containing solution are mixed and reacted at a ratio of 1:8 for 10 minutes to obtain an organic phase containing scandium. Wash the scandium-containing organic phase 2 times with 21% hydrochloric acid at a ratio of 1:1 compared to O / A, and the washing time is 5 minutes / time to remove impurities such as part of titanium and iron in the sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com