Deep dedusting and defogging device

A defogging device, deep technology, applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of disorderly flow of liquid and dust, difficult to meet actual requirements, and unfavorable for droplet settlement, so as to avoid The effects of secondary carrying, improved demisting efficiency, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

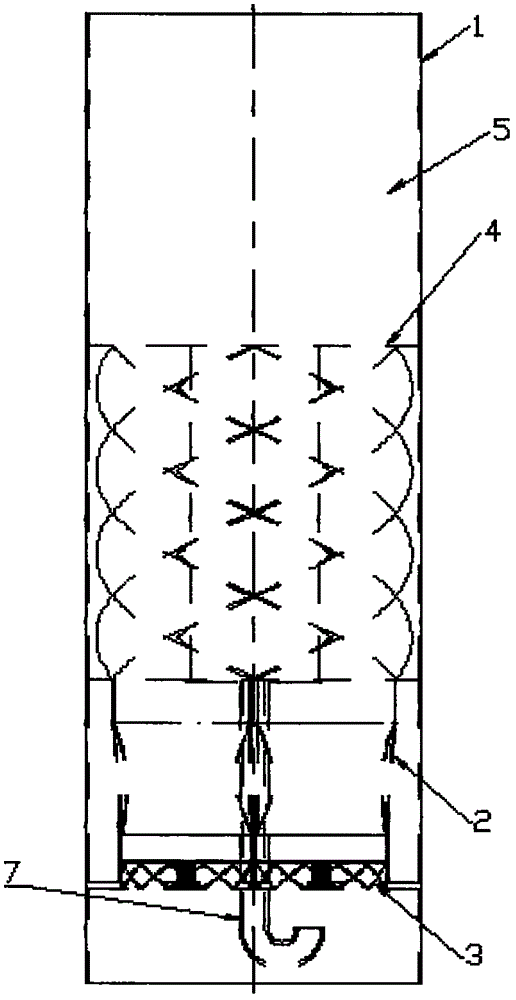

[0040] to combine figure 2 and image 3As shown, the helical channel 4 is a cylindrical helix, and the number of helical turns is not less than half a circle. The cylindrical helix is the helix of the helical channel 4. The front projection of the helix is a sinusoidal curve, and the horizontal projection is a circle. Since the spiral channel 4 is close to the inner wall of the guide tube 1, the gas flowing out from the spiral channel 4 will rise along its tangent, and will be concentrated around the inner wall of the guide tube 1 under the action of the inner wall of the guide tube 1, forming Correspondingly, there is less smoke in the center of the guide tube 1, and most of the smoke continuously collides with the inner wall of the guide tube 1 in the ring-shaped air flow zone, and the smoke flows in a spiral manner. Ascent, the process is longer, so that the fog droplets have sufficient coagulation time, and the demisting effect is improved.

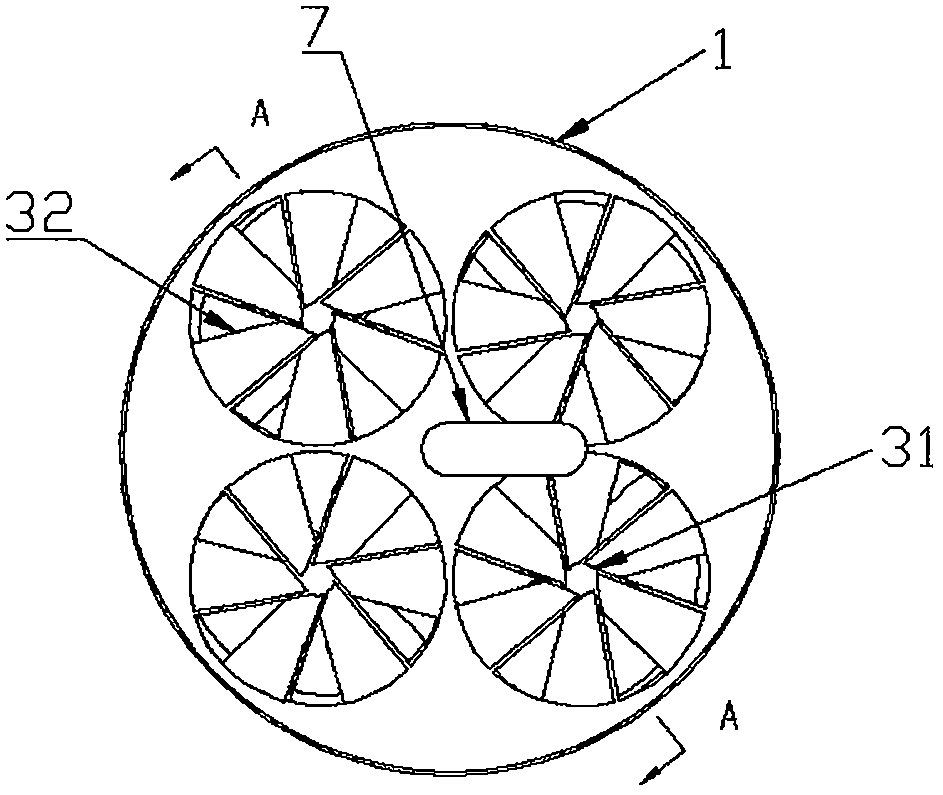

[0041] The center of th...

Embodiment 2

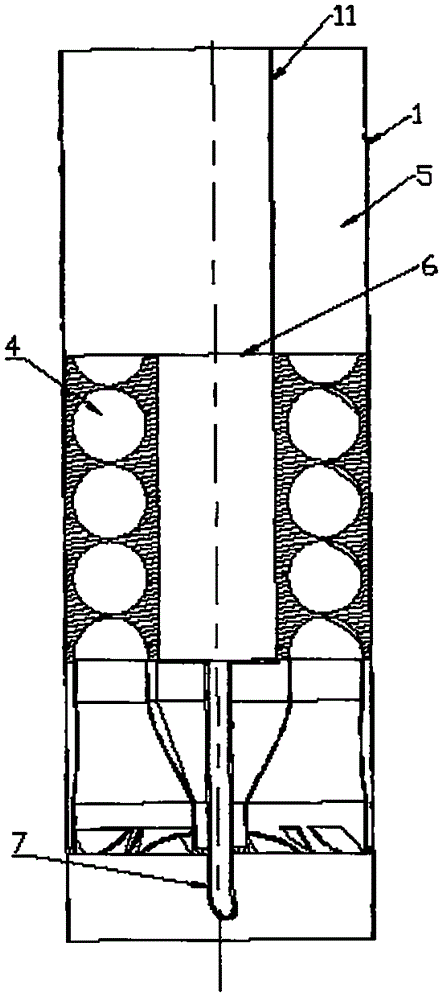

[0051] The difference between this embodiment and Embodiment 1 is that the spiral channel 4 is formed by a plurality of circular tubes spirally along the axial direction of the guide tube 1, the lower end of the circular tube is bent downward to connect with the air flow channel 2, and the upper end is connected to the cavity 5 connected, and the end port is a horizontal cut. Forming the spiral channel 4 in a circular pipe spiral can reduce the amount of processing and reduce the processing cost.

[0052] The guide tube 1 is cylindrical, the spiral channel 4 is installed in the guide tube 1, and its outer wall is attached to the inner wall of the guide tube 1, that is, the outer diameter of the spiral channel 4 is slightly smaller than the inner diameter of the guide tube 1 , the upper and lower ends of the spiral channel 4 are respectively provided with end plates 9, the end plates 9 are used to prevent mist or water droplets from entering the gap between the spiral channel 4...

Embodiment 3

[0054] The difference between the present embodiment and the first embodiment is that the structure of the spiral channel 4 is different. The guide tube 1 of the present embodiment is cylindrical, and a support tube 62 is arranged in the center thereof, and the diameter of the support tube 62 is smaller than that of the guide tube. The inner diameter of the tube 1 is welded with a spiral plate 41 surrounding the support tube 62. The spiral plate 41 is located in the annular area between the guide tube 1 and the support tube 62, and connects the guide tube 1 and the support tube 62. The annular area between them is divided into several separate passages. The spiral plate 41 spirally rises around the support tube 62, its inner side is connected with the outer wall of the support tube 62, and its outer side is connected with the inner wall of the guide tube 1. The adjacent two spiral plates 41 and the outer wall of the support tube 62 and the inner wall of the guide tube 1 jointly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com