Geopolymer-based heavy load pavement paving material and preparation method thereof

A technology of geopolymer and composition, applied in the field of building materials, can solve the problems of easy cracking, weaker strength than concrete, long setting time, etc., and achieve the effects of low cost, low shrinkage, and short setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

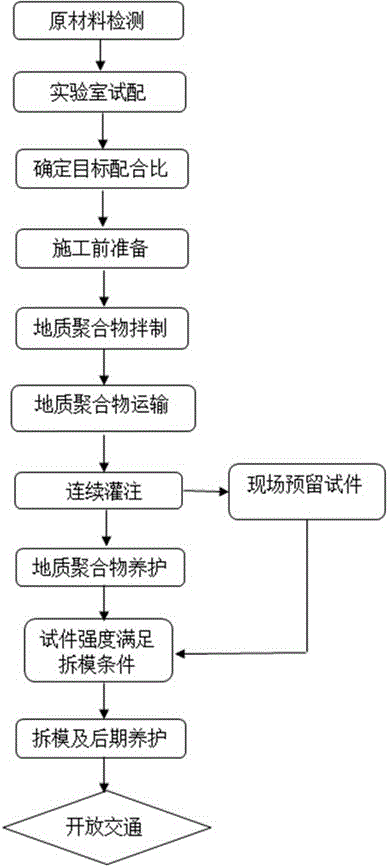

Image

Examples

preparation example Construction

[0034] A preferred preparation method of the material of the present invention comprises the steps of:

[0035] - step (a), uniformly mixing 30 to 40 parts by weight of sodium hydroxide and 240 to 320 parts by weight of water glass with a modulus of 3.2 to obtain an alkaline activator;

[0036] - step (b), respectively sieving metakaolin, slag and fly ash to obtain metakaolin, slag and fly ash with a particle size of 15 to 25 microns;

[0037] - In step (c), 240 to 270 parts by weight of metakaolin, 90 to 105 parts by weight of slag, 40 to 70 parts by weight of fly ash, 580 to 620 parts by weight of river sand, and 1000 to 1200 parts by weight of uniform mix to obtain a mixture;

[0038] -Step (d), adding the basic activator obtained in step (a) to the mixture obtained in step (b) within 30 seconds under stirring, and continuing to stir and react after the addition;

[0039] Among them, the particle size of river sand is 0.3-0.5 mm, and the particle size of basalt gravel is ...

Embodiment 1

[0055] In this embodiment, the composition of the present invention is used to polymerize to form the material of the present invention, and then the material of the present invention is used for road pavement, which specifically includes the following steps:

[0056] Step 1: Mix 240 parts of water glass and 30 parts of sodium hydroxide solid and stir evenly until the sodium hydroxide solid is completely dissolved to obtain an activator, and cool to room temperature for later use.

[0057] Step 2: Grind metakaolin, slag and fly ash to 1250 mesh and sieve.

[0058] Step 3: Take 240 parts, 100 parts, and 60 parts of metakaolin, slag and fly ash respectively, take 580 parts of river sand, and 1000 parts of basalt gravel, start the concrete mixer and stir the dry mixture for 4 to 5 minutes until uniformly mixed, Then add the activator prepared in the first step, add the activator while stirring the dry mixture, and add the activator within 30s. Finally the mixture was stirred for...

Embodiment 2

[0062] In this embodiment, the composition of the present invention is used to polymerize to form the material of the present invention, and then the material of the present invention is used for road pavement, which specifically includes the following steps:

[0063] Step 1: Mix 260 parts of water glass and 32.5 parts of sodium hydroxide solid and stir evenly until the sodium hydroxide solid is completely dissolved to obtain an activator, and cool to room temperature for later use.

[0064] Step 2: Grind metakaolin, slag and fly ash to 1250 mesh and sieve.

[0065] Step 3: Take 250 parts, 95 parts, and 50 parts of metakaolin, slag and fly ash respectively, take 600 parts of river sand, and 1100 parts of basalt gravel, start the concrete mixer to stir the dry mixture for 4-5 minutes until uniformly mixed, and then Add the activator prepared in the first step, add the activator while stirring the dry mixture, and add the activator within 30s. Finally the mixture was stirred fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com