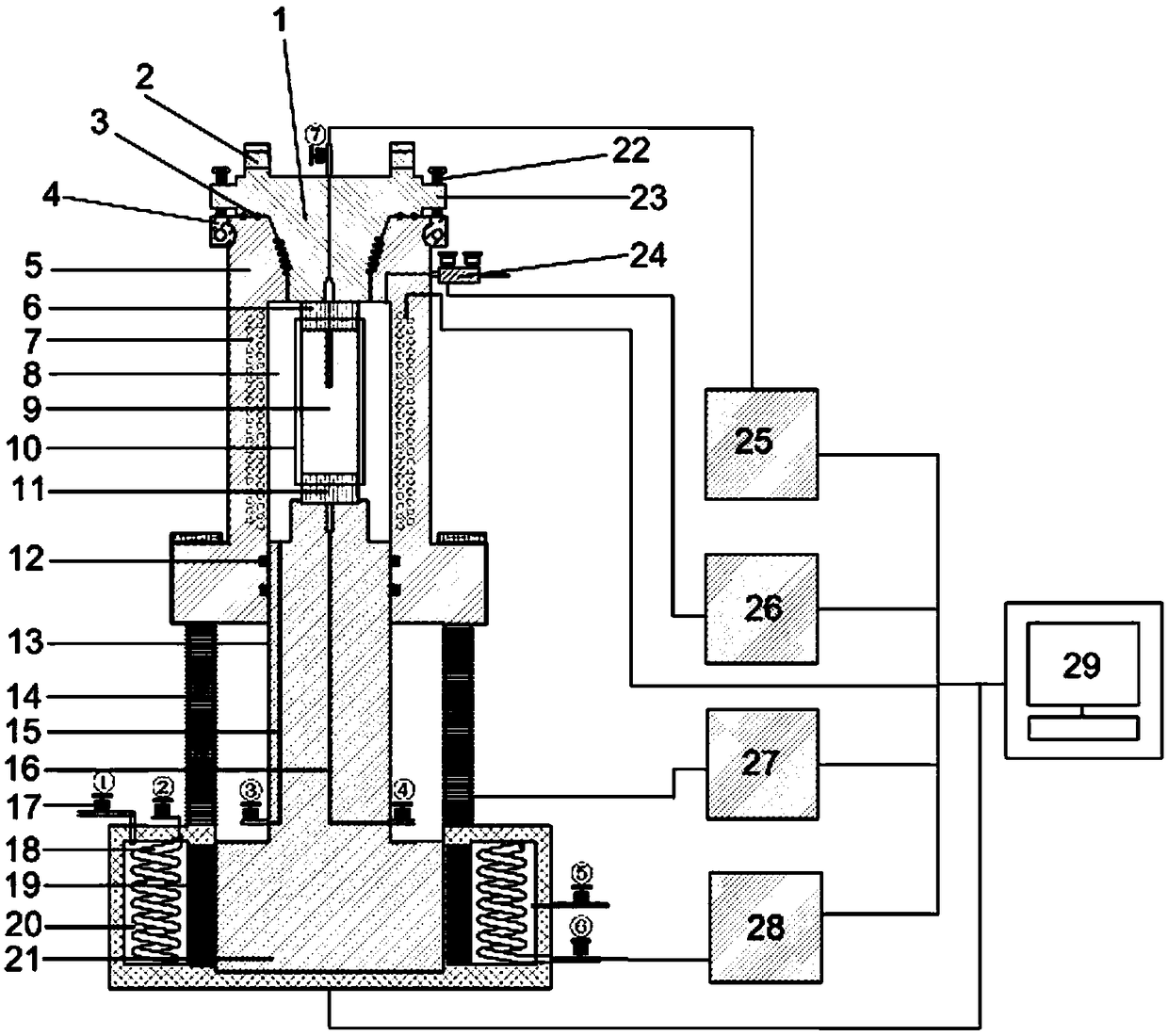

Core test device for high temperature and high pressure hydraulic fracturing and triaxial test

A hydraulic fracturing, high temperature and high pressure technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the complex disassembly process of test instruments, the limitation of the convenience of test devices, and the long cooling time of high temperature oil and other problems, to achieve the effect of shortening the test cycle, simple structure, and easy to constrain the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Examples of hydraulic fracturing

[0038] Step 1, processing the rock core, the rock core is processed by a rock sample cutting machine into a cylindrical shape, and the axis has a water guide hole of a certain depth;

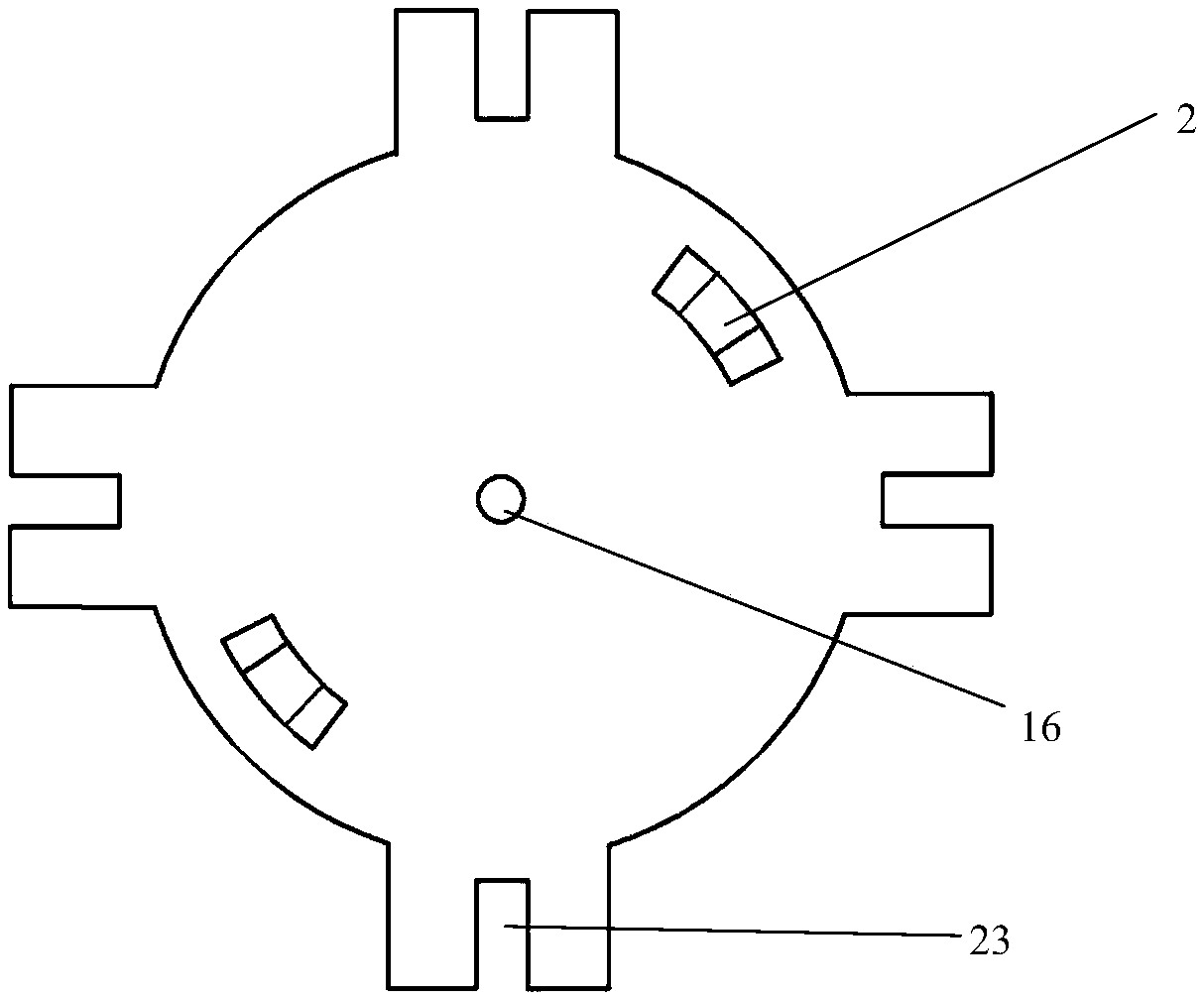

[0039] Step 2: Carry out core clamping outside the cavity 8, respectively place the top pad 6, the rock sample 9, and the bottom pad 11 in the order of upper, middle, and lower, and put them in the high-elastic rubber sleeve 10, and the sleeve The upper and lower ends can be sealed with a closing device;

[0040] Step 3, use a rod-shaped device to cooperate with the removal of the auxiliary hole 2, rotate the top tapered threaded plug 1, and open the upper opening of the cylinder 5;

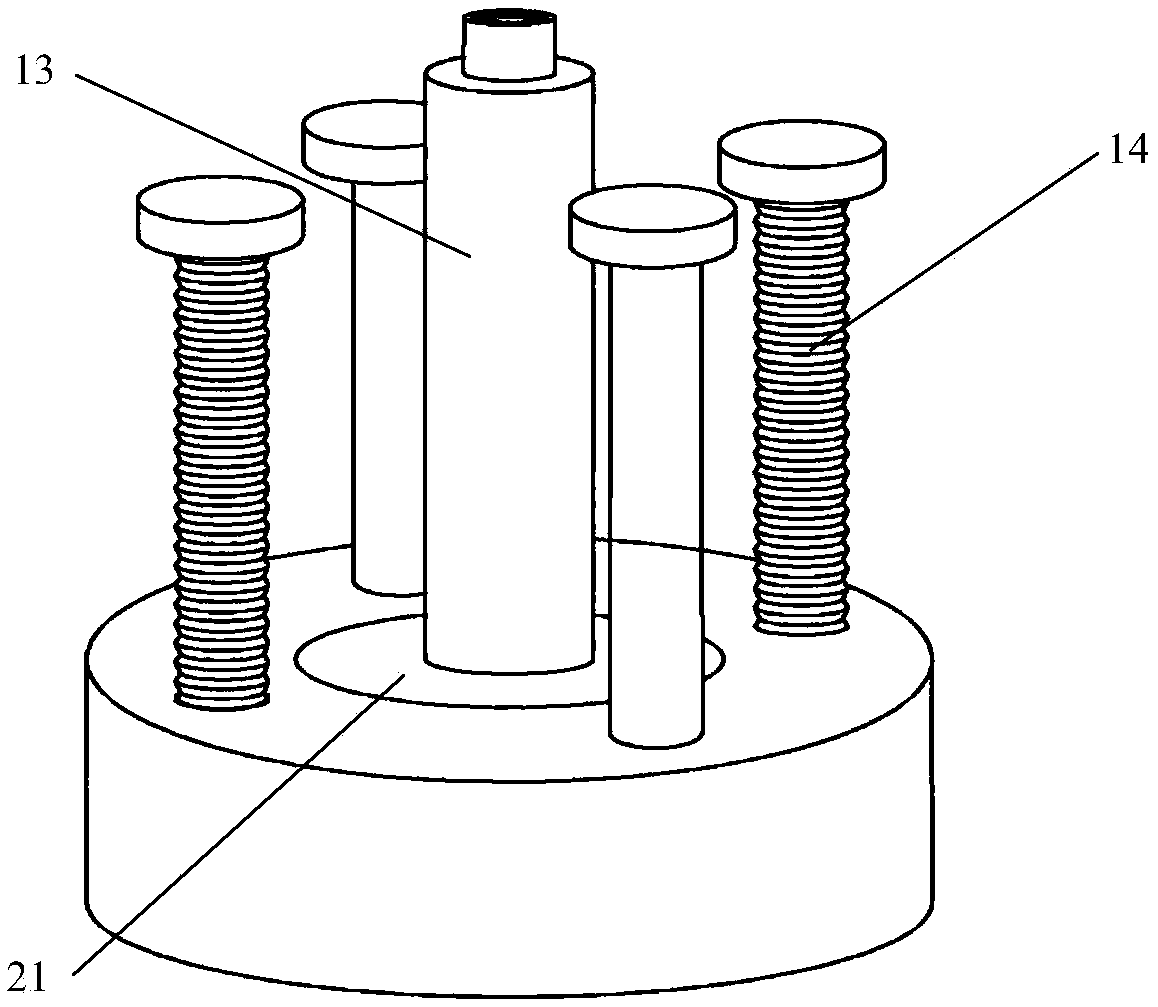

[0041] Step 4, turn on the computer system 9, control the lifting controller 27, and make the cylinder body 5 descend along the threaded axial guide rail 14 until the top of the axial plunger 13 rises to the opening of the cylinder body 5;

[0042] Step 5, insert the clam...

Embodiment 2

[0053] HTHP triaxial embodiment

[0054] Replacement of ordinary pads without applying hydraulic pressure, the steps repeat the steps of the hydraulic fracturing embodiment, and use the servo hydraulic machine 21 to push the axial plunger 13 to apply pressure until the rock sample 9 is destroyed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com