Loop soaking plate

A vapor chamber and loop technology, applied in the field of heat dissipation of electronic components, can solve the problems of aggravating the heat load of the chip, increasing the burning of electronic components, low heat transfer efficiency, etc., to alleviate the heat load problem, speed up replenishment and evaporation , improve the effect of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

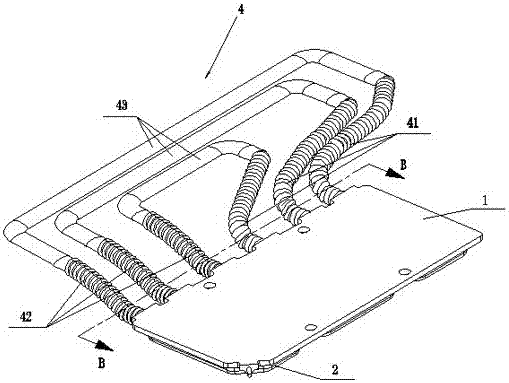

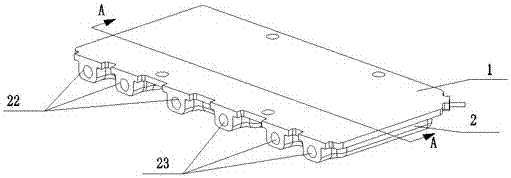

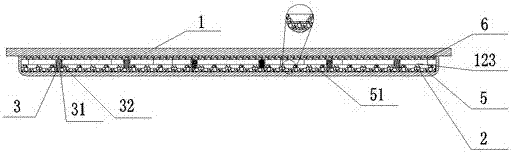

[0032] see Figure 1-Figure 5 As shown, it is the three-dimensional structure diagram and the A-A and B-B cross-sectional views of the first embodiment of the loop vapor chamber structure of the present invention. As shown in the figure, the loop vapor chamber includes an upper cover plate 1, a bottom plate 2, The support structure 3, the capillary structure layer and the loop component 4 that can accommodate the flow of working fluid. In this embodiment, the liquid working medium is preferably distilled water. Wherein, the capillary structure layer includes a first capillary structure layer 5, a second capillary structure layer 6 and a third capillary structure layer 7. In order to increase the capillary adsorption force, a plurality of slopes are arranged on the first capillary structure layer 5. groove 51, the upper cover plate 1 is welded together with the bottom plate 2 provided with a concave square chamber to form a sealed vacuum plate shell 12, the plate shell 12 is f...

Embodiment 2

[0041] see Figure 6 and Figure 7 As shown, it is the three-dimensional structure diagram and the C-C sectional view of the second embodiment using the new loop vapor chamber. As shown in the figure, part of the structure of this embodiment is the same as that of the aforementioned first embodiment, so it will not be repeated here To repeat, the difference between this embodiment and the aforementioned first embodiment is that the liquid pipe body 42 in the loop assembly in this embodiment is a helical copper tube with a fourth capillary structure layer 422 in its inner cavity. The copper powder with a particle size of 80-150 mesh used in the fourth capillary structure layer 422 is sintered. The liquid section pipe body 42 is in a spiral shape, and the pipe diameter of the liquid section pipe body 42 near the condensing unit 43 is smaller than that of the liquid section pipe body 42 near the bottom plate 2, which is favorable for forward circulation flow. Since the inner ca...

Embodiment 3

[0043] see Figure 8 As shown, it is the three-dimensional structure diagram of the third embodiment using the new loop vapor chamber. As shown in the figure, part of the structure of this embodiment is the same as that of the first embodiment, so it will not be repeated here. However, The difference between this embodiment and the aforementioned first embodiment is that both the steam section pipe body 41 and the liquid section pipe body 42 in the loop assembly in this embodiment are made of copper pipes. The copper tube with a simple structure can reduce the manufacturing process of the vapor chamber in this loop, and has little influence on the heat dissipation performance of the overall device.

[0044] The working principle of the present invention is: when the chip with high heat flux density is closely attached to the bottom surface of the bottom plate 2, the heat is transferred to the first capillary structure layer 5 through the bottom plate 2, and the liquid working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com