Biomass quick catalytic pyrolysis device and method

A technology for catalytic pyrolysis and biomass, which is applied in the field of devices for rapid catalytic pyrolysis of biomass, can solve the problems of high material requirements for moving parts, long gas retention time, difficult condensation of pyrolysis gas, etc., and achieves easy recovery of catalyst, regulation and control. Convenience and loss-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

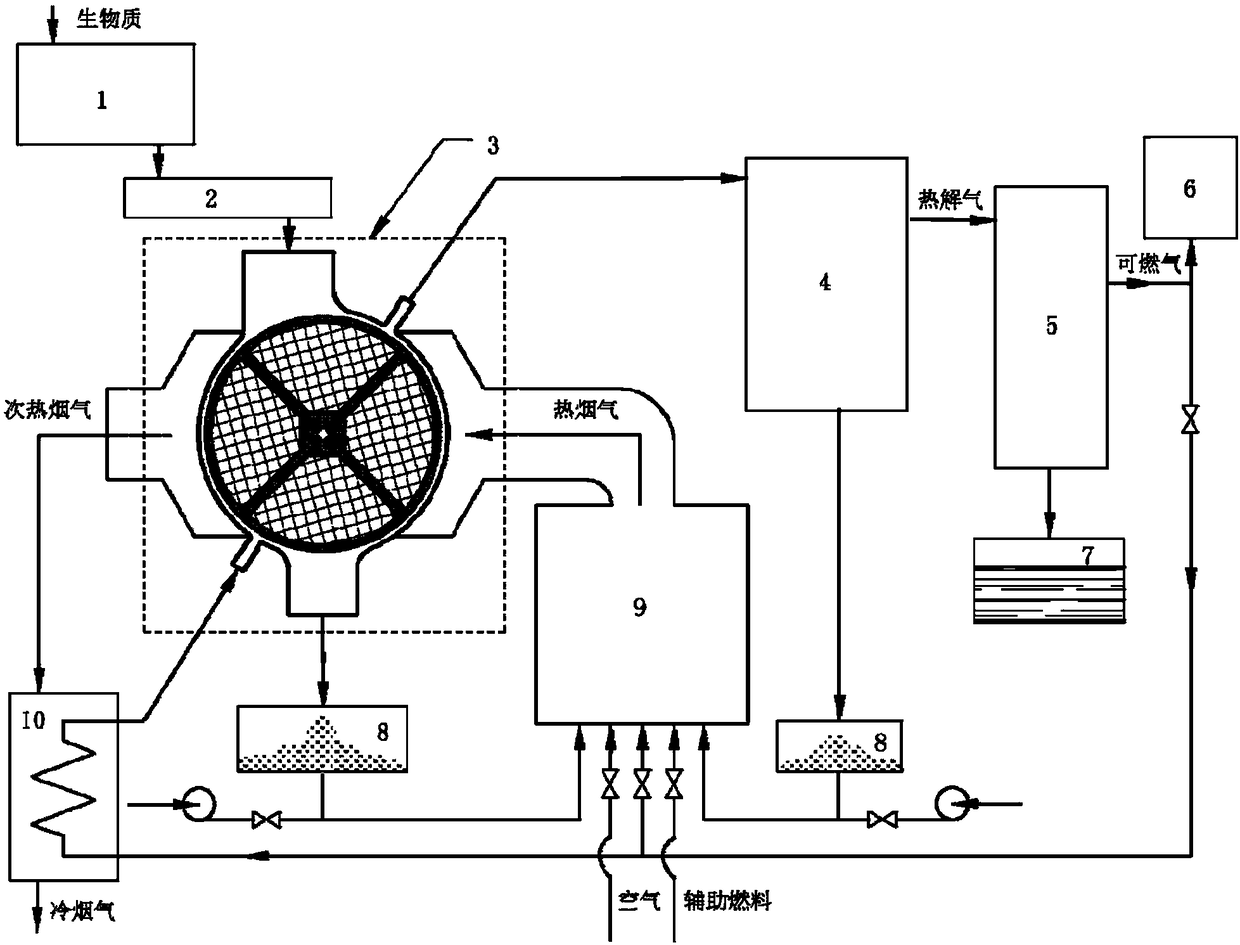

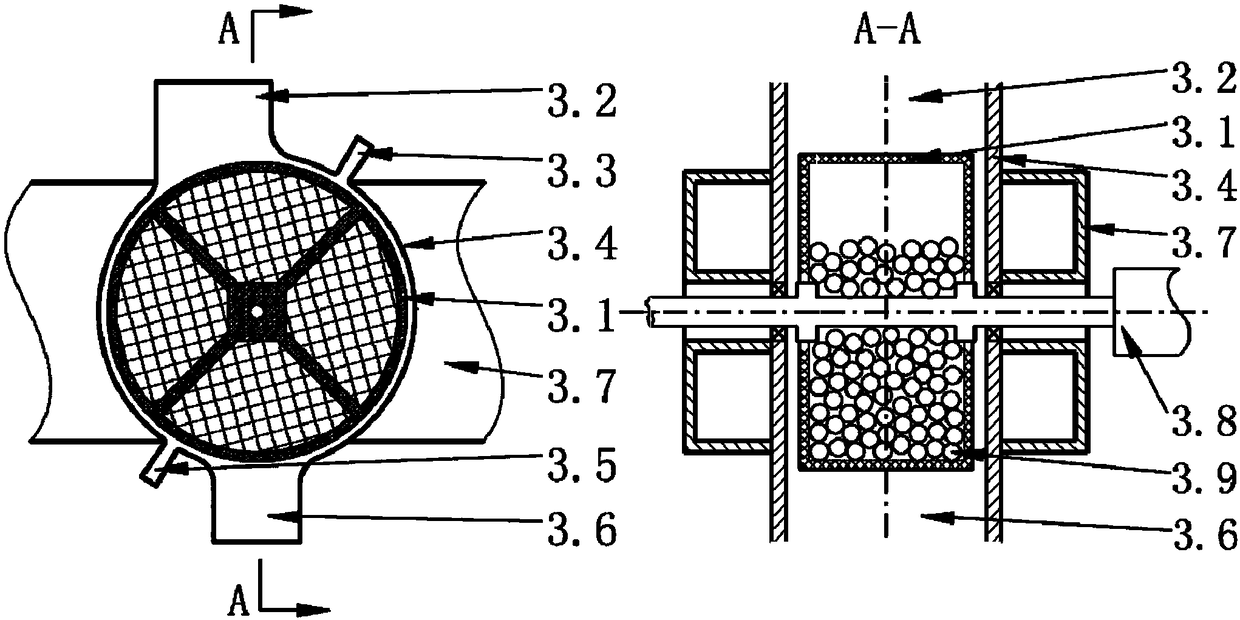

[0043] The cellulose particles with a moisture content of 5% and an average particle size of 1mm are sent to the rotary bed pyrolysis reactor 3 through the hopper 1 and the screw feeding system 2, and the feed rate is 150kg / h; the rotary bed pyrolysis reactor The diameter of the bottom surface of the rotary bed in 3 is 1000mm, the height is 250mm, and the rotation speed is 5.21r / min; the temperature of the flue gas in the heat exchange flue is 560°C, and the pyrolysis reaction temperature is 300°C. It is formed by extrusion of solid phosphoric acid The catalyst with a spherical diameter of 40mm, the filling amount is two-thirds of the rotating bed; after the pyrolysis product is separated from gas and solid and condensed from the pyrolysis gas, the three-phase pyrolysis product of coke, liquid and combustible gas is obtained, and the respective yields are 39%, 49% and 12%. Wherein the yield of target product L-glucosone is 13.8wt%.

Embodiment 2

[0045] The pine wood with a moisture content of 16% is crushed to an average particle size of 1mm, and dried to a moisture content of 8%, and sent to the rotary bed pyrolysis reactor 3 through the hopper 1 and the screw feeding system 2, and the feed amount is 150kg / h; in the rotating bed pyrolysis reactor 3, the diameter of the bottom surface of the rotating bed body is 1000mm, the height is 250mm, and the rotation speed is 5.21r / min; the flue gas temperature in the heat exchange flue is 740°C, and the pyrolysis reaction temperature is 500 ℃, using solid potassium phosphate extruded catalyst with a ball diameter of 30mm, the filling amount is two-thirds of the rotating bed body; after the pyrolysis product is separated from gas and solid and condensed from the pyrolysis gas, coke, liquid and combustible gas are obtained Three-phase pyrolysis products with respective yields of 30%, 47% and 23%. Wherein the relative content of the target product phenolic mixture in the pyrolys...

Embodiment 3

[0047] The bagasse is crushed to an average particle size of 1mm, and dried to a moisture content of 8%, and sent to the rotary bed pyrolysis reactor 3 through the hopper 1 and the screw feeding system 2, and the feed rate is 150kg / h; The diameter of the bottom surface of the rotating bed in the decomposition reactor 3 is 1000mm, the height is 250mm, and the rotation speed is 5.21r / min; the temperature of the flue gas in the heat exchange flue is 580°C, and the pyrolysis reaction temperature is 310°C, activated by steam Activated carbon extruded catalyst with a ball diameter of 40mm, the filling volume is two-thirds of the rotating bed body; after the pyrolysis product is separated from gas and solid and condensed from the pyrolysis gas, the three-phase pyrolysis product of coke, liquid and combustible gas is obtained , with yields of 51%, 36% and 13%, respectively. Wherein the yield of target product 4-ethylphenol is 3.4wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com