Catalyst for low-temperature catalytic combustion of volatile organic compounds and preparation method thereof

A technology of volatile organic compounds and low-temperature catalysis, applied in combustion methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of low anti-poisoning ability, high price, and low ignition temperature and other problems, to achieve the effect of excellent activity, simple preparation process and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of catalyst of the present invention is characterized in that: Al 2 o 3 Carrier, RE 2 o 3 -Al 2 o 3 The surface area of composite oxide is 80~326m 2 / g. The active component palladium is loaded by an equal volume impregnation method, so that the particle size of the palladium is 1-50 nm. The catalyst preparation steps include in turn:

[0020] (1) Preparation of aluminum hydroxide and rare earth hydroxide mixture by co-precipitation method;

[0021] (2) Dry the hydroxide obtained above at 80-120°C in an air atmosphere, and then calcinate at 500-900°C to obtain RE 2 o 3 -Al 2 o 3 composite oxides;

[0022] (3) Equal volumes of the composite oxide obtained above are impregnated with the precursor solution of the active component, dried at 50-120°C step by step, and then calcined at 500-900°C.

[0023] In the above catalyst preparation method, the active component precursor in step (3) is a soluble palladium metal inorganic salt, prefe...

Embodiment 1

[0025] Weigh 56.2690g of Al(NO 3 ) 3 9H 2 O and 3.2876g of Nd(NO 3 ) 3 ·6H 2 O is placed in a conical flask, and water is added to 200ml. After the salt is completely dissolved, 28% ammonia water is added under the condition of electric stirring until the pH of the solution is 8-10. After stirring for 1 hour, the precipitate is left standing, centrifuged, and 120 ℃ for 12 hours, and then baked in muffle furnace air at 800 ℃ for 4 hours to obtain composite oxides. The specific surface area of the composite oxide measured by a physical adsorption instrument (Micromeritics ASAP 2020) is 186.8 m 2 / g.

[0026] Then, grind and sieve, take a 30-80 mesh composite oxide carrier, and use an equal volume impregnation method to load Pd with a mass fraction of 0.5%. The specific process is as follows: take a certain volume of Pd solution to impregnate the carrier, stir for 5 minutes, ultrasonically sonicate for 10 minutes, then bake in an oven at 50°C for 0.5h, at 80°C for 0.5h, ...

Embodiment 2

[0029] RE 2 o 3 -Al 2 o 3 The preparation method of the composite oxide and the loading mode of the noble metal Pd are the same as in Example 1, except that the added rare earth nitrate is 0.5149g of Gd(NO 3 ) 3 ·6H 2 O, the calcination temperature of the composite hydroxide and the oxide after loading Pd is 600°C.

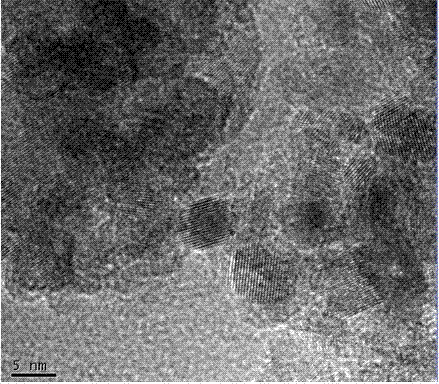

[0030] The specific surface area of the composite oxide was measured by a physical adsorption instrument to be 186.8 m 2 / g. Transmission electron microscope (if attached figure 1) indicates that the size of the noble metal palladium particles in the catalyst is about 6 nm.

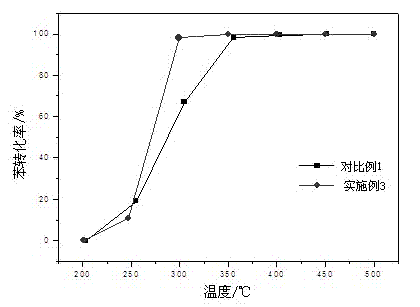

[0031] The activity evaluation method of the catalyst is the same as in Example 1. The experimental results showed that when the reaction temperatures were 200, 250, 300, 350, 400, 450, 500°C, the conversions of benzene were 10.85, 64.89, 99.65, 99.97, 100, 100, and 100%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com