Method and device for hydrogenating whole-fraction medium and low-temperature coal tar to prepare mononuclear aromatics

A low-temperature coal tar and single-ring aromatics technology, applied in the field of single-ring aromatics, can solve problems such as corrosion of equipment, influence on device operation, and high molecular weight, and achieve the effects of increased yield, stable equipment operation, and good product yield effects

Active Publication Date: 2017-05-24

NORTHWEST UNIV

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Compared with the yield of single-ring aromatics obtained in the present invention, its disadvantage is that the yield of single-ring aromatics in the process product is the highest not more than 40%, and the development prospect is particularly poor

[0006] The invention patent with the notification number CN101712889B discloses a method for producing light aromatics from coal tar. The process is to perform two-stage selective hydrotreating of light oil fractions less than 200°C by fractional distillation to obtain the desired product, but for The heavy fraction at 200°C is not fully utilized to produce light aromatics, and the yield of light aromatics produced is low

[0007] There are many papers on the production of BTX single-ring aromatics, such as the technical prospect of increasing the production of BTX aromatics by lightening the heavy distillate of pyrolysis gasoline, the research on the catalytic reaction of BTX produced by phenanthrene hydrocracking, the molecular level research on the production o

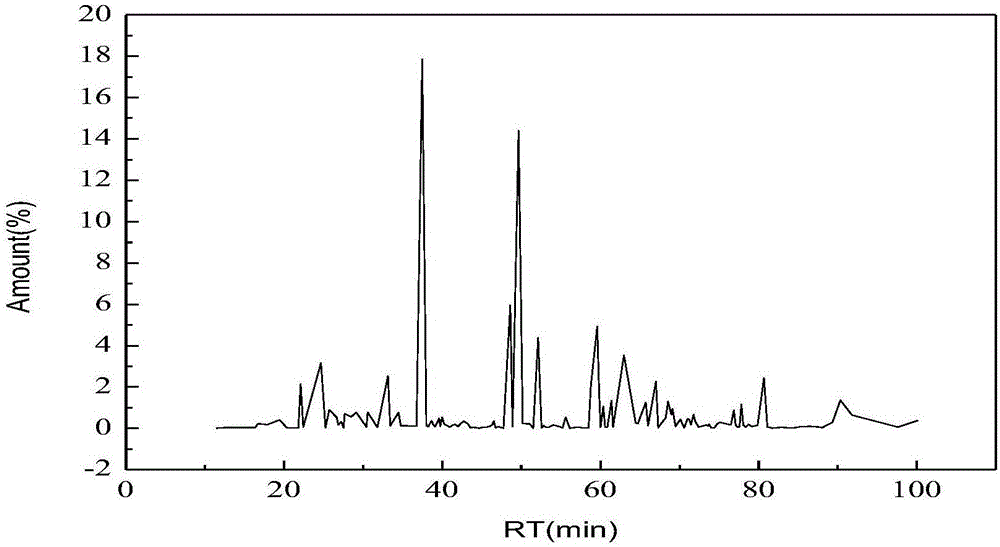

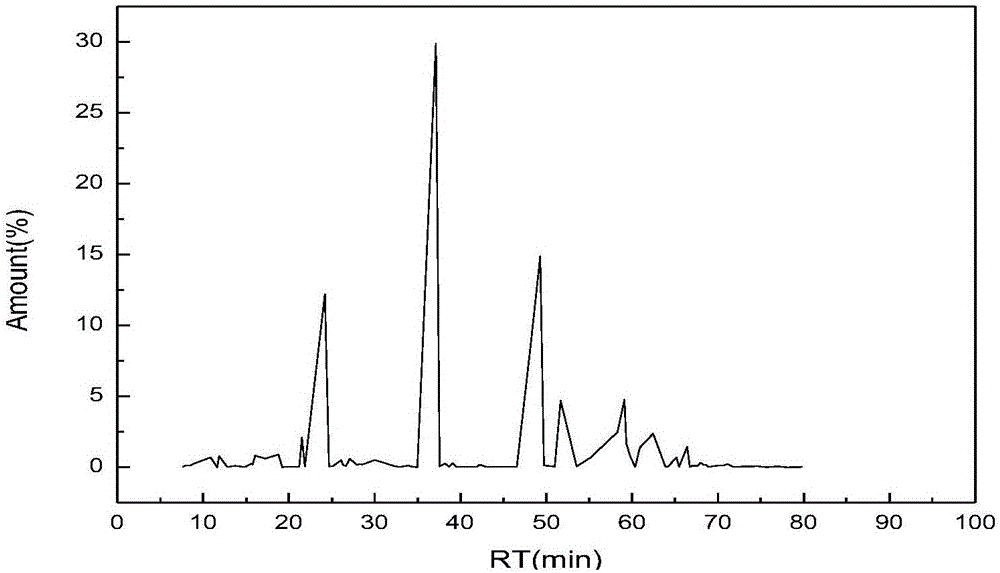

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

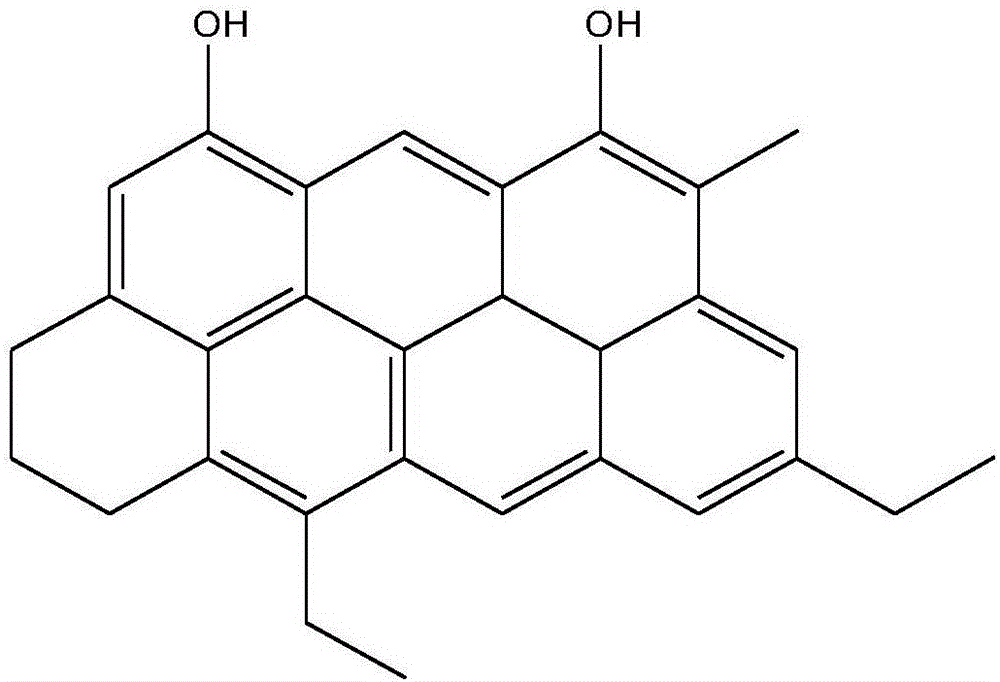

The invention relates to a method and a device for hydrogenating whole-fraction medium and low-temperature coal tar to prepare mononuclear aromatics. The method comprises the following steps of (1) sending the whole-fraction medium and low-temperature coal tar into a fractionating tower for fractionation, and obtaining a material flow II which is fractionated from the bottom part of the fractionating tower, and a material flow I which is fractionated from the top part of the fractionating tower; directly sending the material flow I into step (2); directly sending the material flow II into step (3); (2) preparing the material flow I obtained in step (1) by a conventional technology to obtain the mononuclear aromatics; (3) hydrogenating and degrading the material flow II obtained in step (1), sending the hydrogenated and degraded material flow into the step (2), and preparing the mononuclear aromatics by the conventional technology. The method and the device for hydrogenating the whole-fraction medium and low-temperature coal tar to prepare the mononuclear aromatics have the advantages that the whole-fraction medium and low-temperature coal tar is used as raw material to be fractionated, the light phase is cracked and refined, and the heavy phase is cracked twice, refined and cracked; the hydrogenation of whole-fraction coal tar to prepare the mononuclear aromatics of benzyl, methylbenzene, xylene and the like is realized.

Description

technical field [0001] The invention belongs to the field of chemical industry, and relates to a method and device for producing monocyclic aromatic hydrocarbons by hydrogenating whole fractions of medium and low temperature coal tar, in particular to a kind of whole fractions of medium and low temperature coal tar as raw materials through fractionation, cracking and refining the light phase, and refining the heavy phase. A method and device for producing single-ring aromatic hydrocarbons such as benzene, toluene, and xylene by performing two crackings and then refining the cracking process route. Background technique [0002] With the rapid development of the world economy, the demand for various chemical raw materials is also increasing. Among them, benzene, toluene, xylene and other light aromatics, as important chemical raw materials, once became the products with long-term strong demand in the global market. [0003] For a long time, my country has been a country rich i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G67/02

CPCC10G67/02C10G2400/30

Inventor 李冬王莉莎牛梦龙崔文岗李稳宏

Owner NORTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com