System and process for treating water-based ink of printing plant to surface water discharge

A water-based ink and surface water technology, applied in filtration treatment, sedimentation treatment, multi-stage water treatment, etc., can solve the problems of secondary pollution, poor biodegradability, and high cost of wastewater treatment, and achieve stable equipment operation, simple system, and easy treatment. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

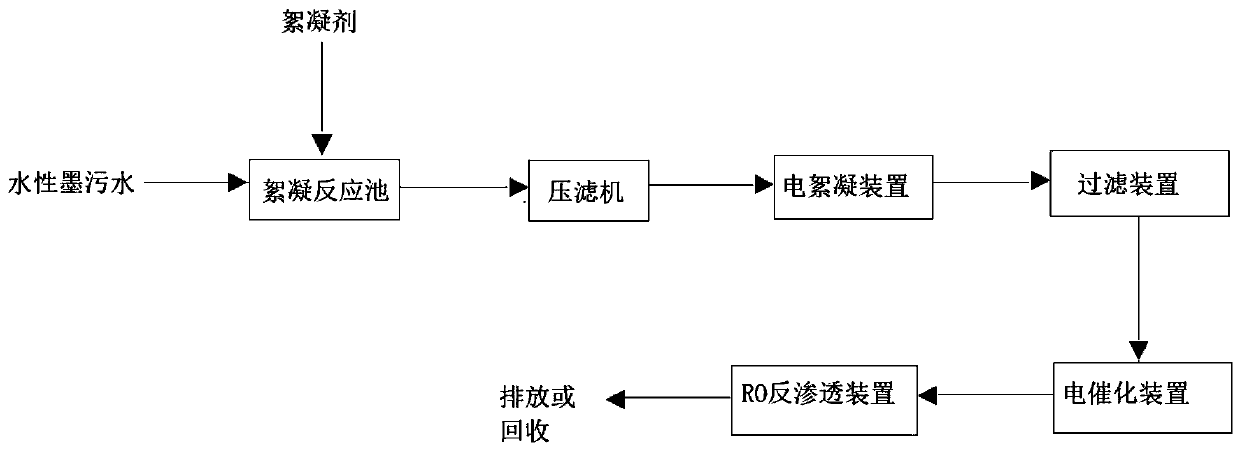

[0029] Such as figure 1 As shown, a system for treating water-based ink discharged from a printing factory to surface water in this embodiment includes a flocculation reaction tank connected in sequence, a filter press, an electroflocculation device, a filter device, an electrocatalytic device and RO reverse osmosis device.

[0030] Among them, the reaction devices are connected by pumps, and the sewage from the previous treatment process is pumped into the next treatment process. A stirring device is fixedly installed in the flocculation reaction tank. In the present invention, the water-based ink sewage is pumped into the flocculation reaction tank. In the reaction tank, a flocculant is added to the reaction tank to carry out flocculation reaction. After fully stirring and standing still, flocculation reaction occurs to separate solid and liquid.

[0031] The anode in the described electrocoagulation device is aluminum metal, and the cathode is aluminum metal. In this embod...

Embodiment 2

[0033] A process of using the system in this embodiment to treat the discharge of water-based ink to surface water in printing plants, the process is as follows: pump the water-based ink sewage into the flocculation reaction tank, and pump the sewage after the flocculation reaction into the filter press Pressure filtration is carried out in the machine, and the sewage after pressure filtration is pumped into the electroflocculation device for electrocoagulation treatment, the sewage after electrocoagulation is pumped into the filter device, the filtered sewage is then pumped into the electrocatalysis device, and the treated sewage is pumped into RO reverse osmosis device, the clean water after reverse osmosis treatment is discharged or recycled.

[0034] This embodiment takes the treatment of 1 ton of water-based ink sewage as an example to explain. The water-based ink sewage is pumped into the flocculation reaction tank, and 4000g of flocculant is added to the reaction tank to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com