Net punching mechanism for lead acid battery slab lattice

A lead-acid battery and grid technology, which is applied in the field of battery grid production, can solve the problems of punch press stroke and speed adjustment difficulties, large vibration and noise, and bulky punch press, so as to reduce the overall volume of the equipment, and the equipment runs smoothly. Reasonable effect of structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

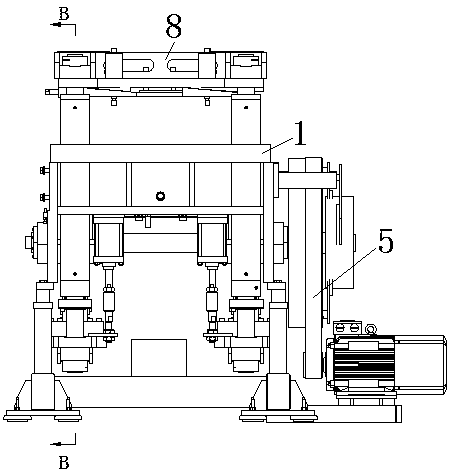

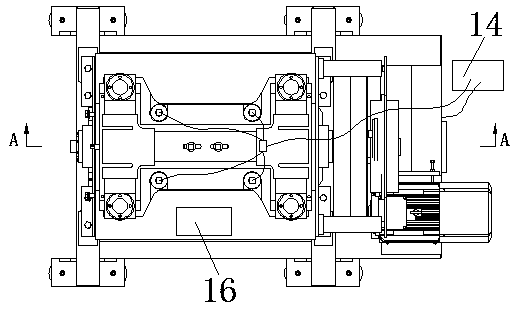

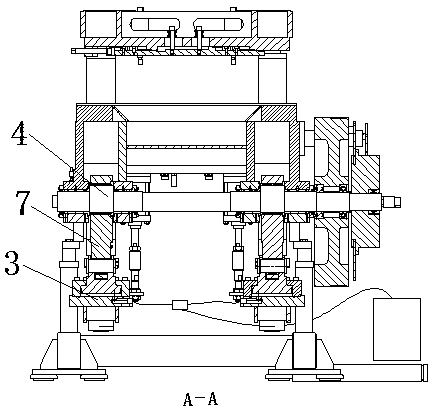

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a kind of flushing mechanism for lead-acid battery grid of the present invention, it comprises frame 1, is arranged with four guide pillars 2 symmetrically on both sides of described frame 1, two on the same side The lower part of the guide post 2 is fixed by the guide post connecting block 3, a main shaft 4 is provided at the bottom of the frame 1, a reduction transmission structure 5 is provided at one end of the main shaft 4, and two eccentric shafts are arranged on the main shaft 4. Wheel 6, on the eccentric wheel 6 is provided with a connecting rod 7, the lower end of the connecting rod 7 is hinged with the guide post connecting block 3, and an upper mold frame assembly 8 is provided on the top of the guide post 2, the upper die The frame assembly 8 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com