Ball screw pair loading test device and test method

A technology of loading test device and ball screw pair, which is applied in the field of ball screw, can solve the problems of slow response of loading output force, affecting the development and performance optimization of ball screw, and affecting the accuracy of operating parameters, etc., to achieve fast response and overall Reasonable structure setting and the effect of ensuring accuracy

Active Publication Date: 2021-04-13

SHANDONG UNIV

View PDF20 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The load characteristics of the traditional ball screw are mainly obtained by the cylinder loading, motor torque loading, and magnetic particle actuator loading tests. These loading methods have been widely used in the design and development of the ball screw pair simulation test bench. Screw design theory combined with empirical design is still the main method for ball screw design and selection under this extreme working condition at present, and t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

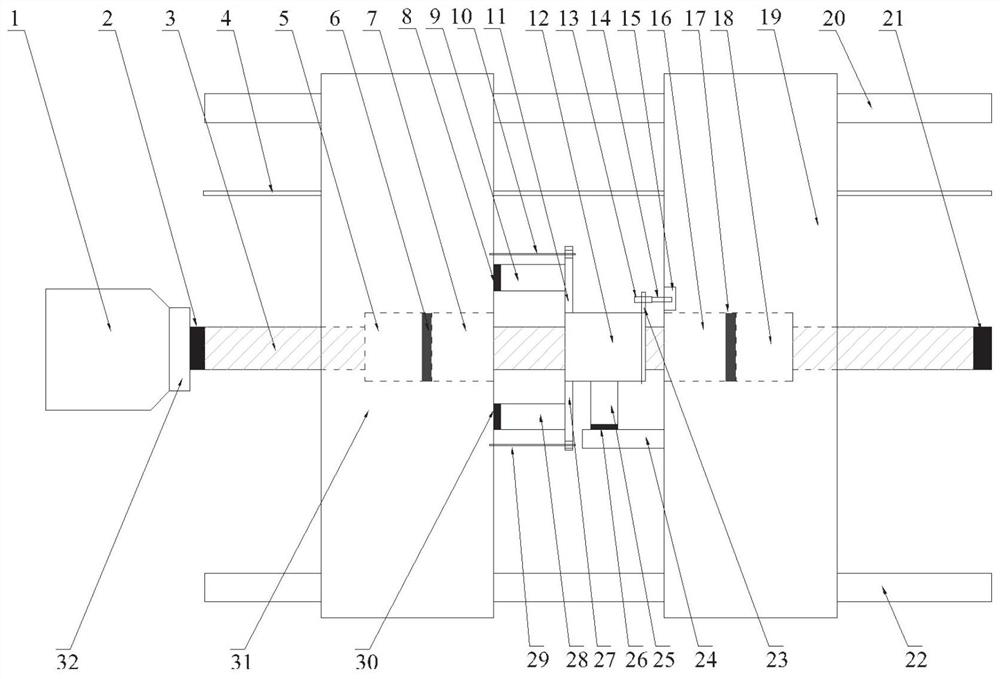

The invention discloses a ball screw pair loading test device and a test method, solves the problem of low accuracy of parameters obtained by a test in the prior art, and has the beneficial effect of effectively obtaining the parameters in the loading process. The specific scheme is as follows: the ball screw pair loading test device comprises a ball screw, the ball screw is provided with at least one working table plate through a nut pair, a test nut can be installed on the ball screw, at least one side of the end of the test nut is connected with a supporting piece, an expansion device is arranged between the working table plate and the supporting piece, a pressure sensor is arranged between the expansion piece and the working table plate on one side, the arrangement direction of the expansion piece is parallel to the arrangement direction of the ball screw, and a load is applied to the end part of the test nut through the expansion piece.

Description

technical field [0001] The invention relates to the field of ball screws, in particular to a ball screw pair loading test device and a test method. Background technique [0002] The statements in this section merely provide background information related to the present invention and do not necessarily constitute prior art. [0003] With the rapid development of aerospace and other defense industries and deep-sea operation equipment, such as the opening and closing of spacecraft hatches, the retraction and retraction of aircraft landing gear, the deployment of solar panels, the control of injection molding machinery mold clamping, and the swing of robotic arms for deep-sea operations As well as many important applications such as the switch of nuclear power plant valves, ball screws are used as transmission elements. The electromechanical servo transmission mechanism composed of the ball screw pair requires a small structure size, and under the working conditions of impact l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/025

CPCG01M13/025F16H2025/2075F16H25/2204

Inventor 林明星赵佳佳吴筱坚宋现春荣柏松

Owner SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com