Novel swash plate structure with wear resistance and convenient connection

A swash plate, a new type of technology, is applied in the direction of liquid variable displacement machines, reciprocating piston engines, variable displacement engines, etc. It can solve the problems of extremely high friction surface hardness, loss of control of the swash plate, high cost, etc., and achieve light weight , the use of flexible, reduced cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

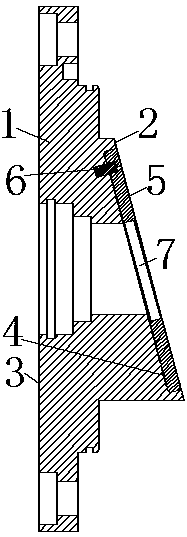

[0010] Such as figure 1 As shown in the present invention, a new type of swash plate structure with convenient wear-resisting connection, the original shell is split into two parts, the shell and the back cover 1, and a swash plate slope is provided at one end of the back cover 1 2. The other end is a connection plane 3, and a thrust plate installation groove 4 is provided on the swash plate slope 2, and the thrust plate installation groove 4 is a circular groove, and a thrust plate installation groove 4 is provided in the thrust plate installation groove 4. Thrust plate 5 is arranged, and described thrust plate 5 is superhard super wear-resisting thrust plate, and the outer end surface of described thrust plate 5 and the outer end surface of thrust plate installation groove 4 are arranged on the same plane, and they two The thrust plate 5 is fixed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com