Multi-core combined electric power cable

A technology of power cables and conductive units, which is applied in the field of multi-core power cables, can solve the problems that single-core power cables cannot meet the use requirements, the overall strength of the cables is not enough, and the shielding effect is not good, etc., to achieve good filling effects and overall structure settings Reasonable, good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

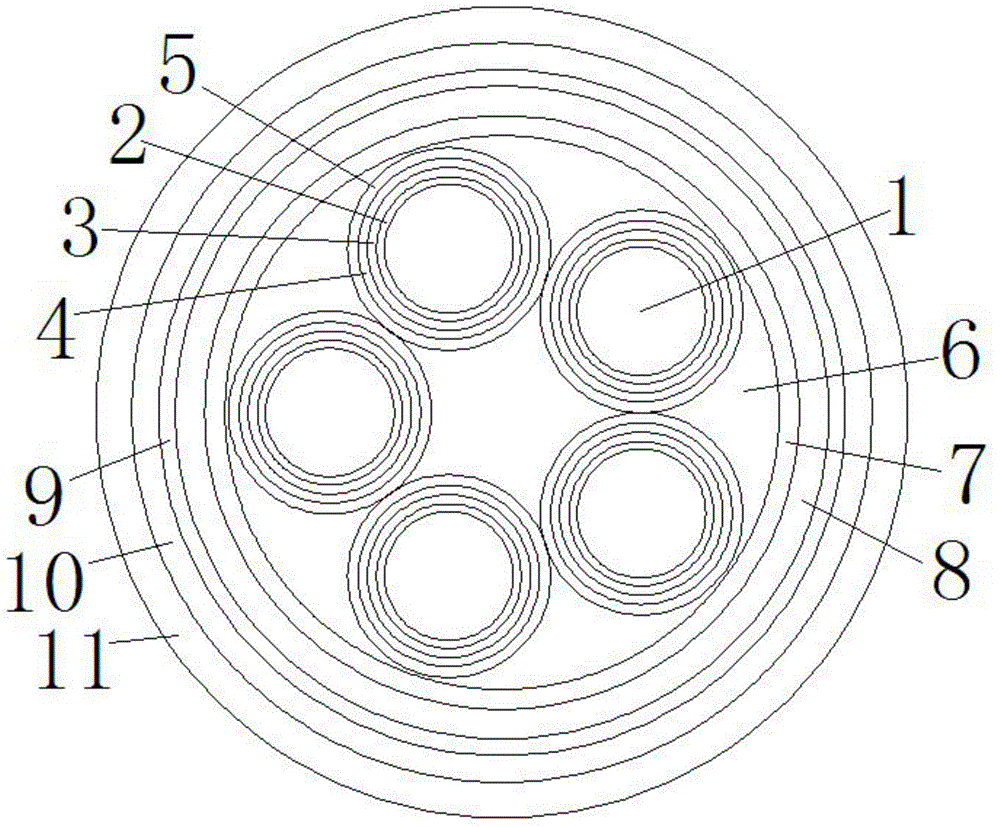

[0013] like figure 1 As shown, a multi-core combined power cable according to the present invention includes an oxygen-free copper conductor 1, an inner shielding layer 2 is arranged outside the oxygen-free copper conductor 1, and an inner shielding layer 2 is arranged outside the inner shielding layer 2. An inner insulating layer 3, an outer shielding layer 4 is arranged outside the inner insulating layer 3, an outer insulating layer 5 is arranged outside the outer shielding layer 4, the inner shielding layer 2, the inner insulating layer 3, the outer shielding layer 4 and the outer insulating layer 5 are co-extruded from four layers. The oxygen-free copper conductor 1, the inner shielding layer 2, the inner insulating layer 3, the outer shielding layer 4 and the outer insulating layer 5 form a conductive unit, and the conductive unit is at least Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com