Claw type safety clutch

A clutch and claw-type technology, applied in the field of claw-type safety clutches, can solve the problems of large occupied space and many maintenance costs of parts, and achieve the effects of stable equipment operation, low use cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

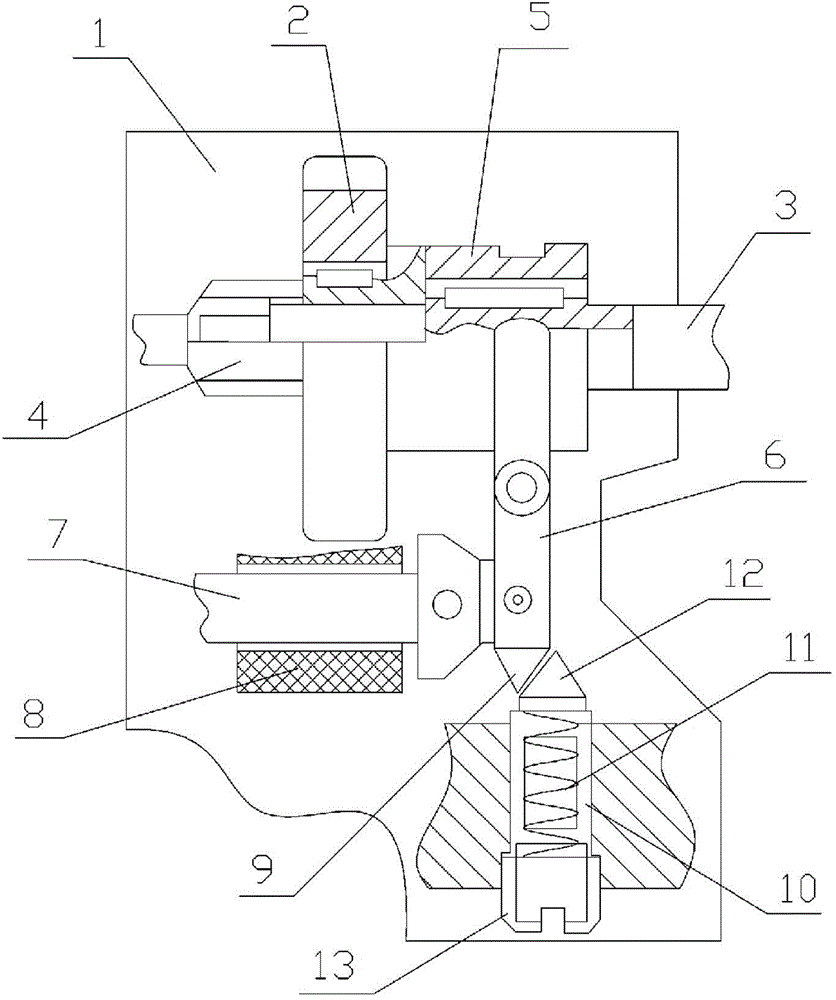

[0012] The reference signs in the drawings of the specification include: machine base 1, driving wheel 2, driven shaft 3, main shaft 4, clutch 5, lever 6, pull rod 7, motor 8, first contact 9, sliding sleeve 10, compression spring 11, the second contact 12, the adjustment screw 13.

[0013] Such as figure 1 As shown, the claw safety clutch includes a machine base 1, a driving wheel 2 and a driven shaft 3. The main shaft 4 connected to the reduction box is arranged in the machine base 1, the driving wheel 2 is fixedly connected to the main shaft 4, and the driven shaft 3 is The clutch 5 is fixed, the drive wheel 2 is provided with a tooth surface, the clutch 5 is provided with a flywheel, the flywheel is connected with the tooth surface, the driven shaft 3 is connected with the hoisting mechanism of the crane, and the clutch 5 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com