Small steam turbine high-pressure steam source rotationimpulsing method and control system thereof

A control system and small steam turbine technology, applied in the direction of mechanical equipment, engine components, engine starting, etc., can solve problems such as inability to put into operation, low-pressure steam source does not have enough lifting force, and small steam turbines cannot be reversed, etc., to achieve equipment operation Smooth, smooth running, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The existing small steam turbine control system is the 505 controller, which is a packaged encryption program (black box control), does not have the logic expansion function, and cannot redesign the small steam turbine control logic. Based on this kind of controller, if a high-pressure steam source is used for running, the controller cannot adjust the system fluctuations caused by the high-pressure gas source running, so in extreme cases, it can only rely on manual running to take risks. But the operation here is dangerous, and the system is still unstable.

[0020] For the actual equipment design of the present invention, at first small steam turbine is carried out unit transformation:

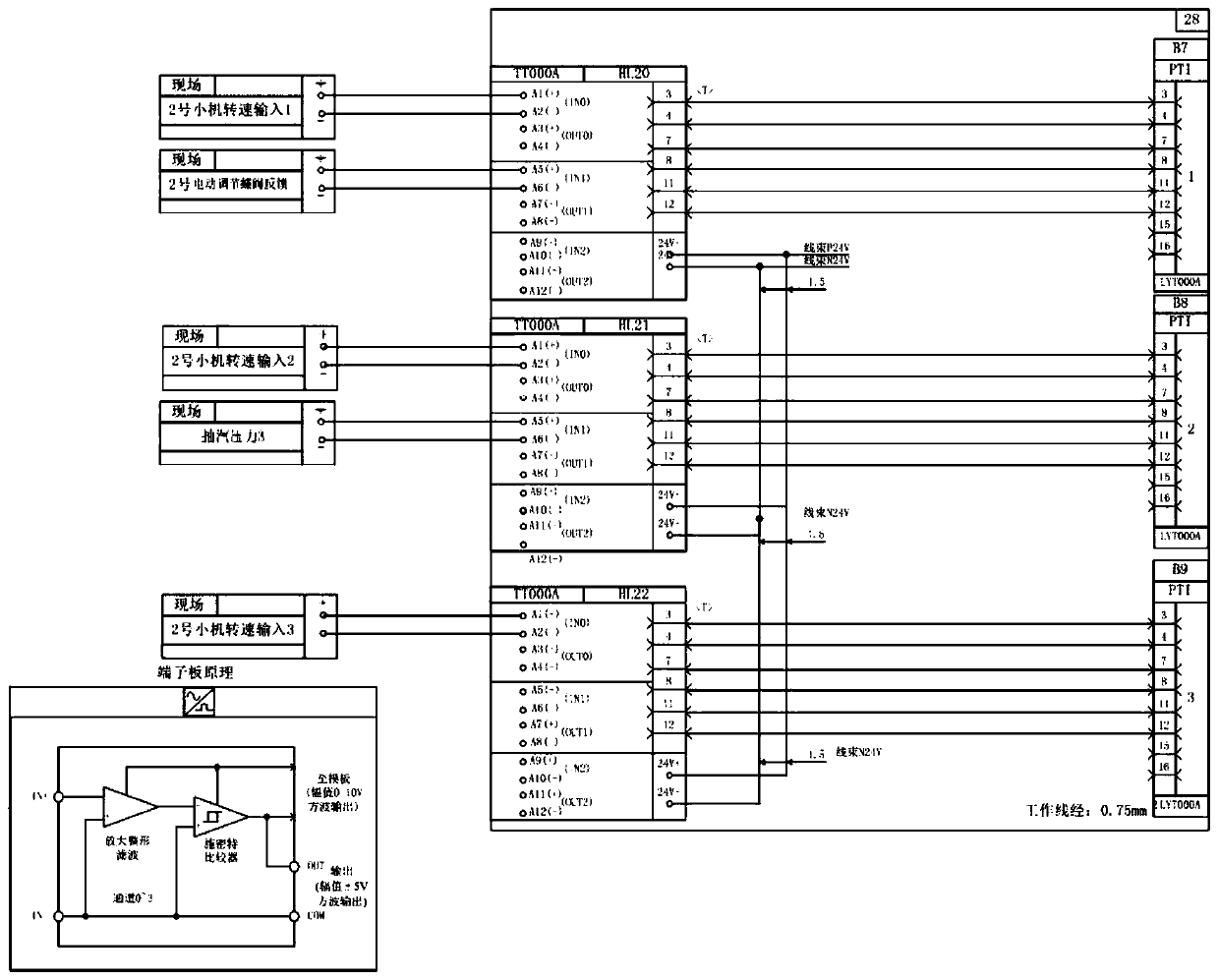

[0021] The original old 505 controller is replaced by the DCS controller, and the MEH small steam turbine control system is added to the DCS controller. MEH is responsible for the operation control of the steam source of the small steam turbine. Connect the field equipment originally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com