Method for producing benzene, toluene and xylene from poor-quality diesel oil raw material

A low-quality diesel and xylene technology, applied in the field of hydrocarbon oil cracking, can solve the problem of low octane number of gasoline fractions, and achieve the effects of good synergy, excellent selectivity and excellent selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

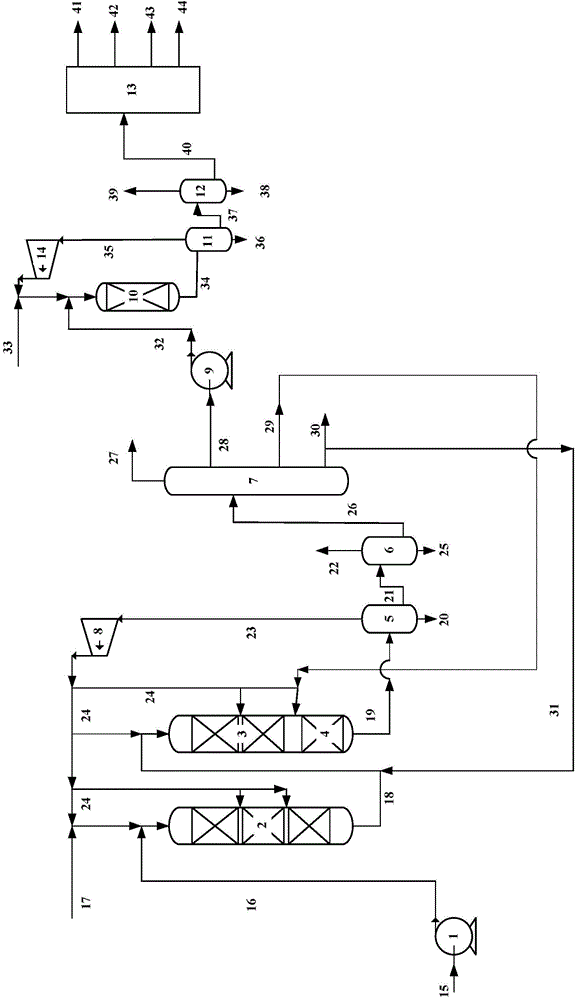

Image

Examples

Embodiment 1

[0052] The feed oil F enters the hydrorefining reaction zone together with the hydrogen, contacts and reacts with the protective agent A and the hydrofinishing catalyst B, and the reaction effluent from the hydrofinishing reaction zone enters the hydrocracking reaction zone I without any intermediate separation. The first hydrocracking catalyst C contacts and reacts. After the reaction effluent of hydrocracking reaction zone I is mixed with middle distillate and hydrogen-rich gas, it enters hydrocracking reaction zone II, contacts and reacts with the second hydrocracking catalyst D, and breaks the alkyl side chain, and takes into account the Selective ring-opening cracking of tetrahydronaphthalene monocyclic aromatics. The reaction effluent from hydrocracking reaction zone II enters the separation facilities such as cold high-pressure separator, cold low-pressure separator, fractionation tower, etc. in turn, and obtains light gasoline fraction, heavy gasoline fraction, middle ...

Embodiment 2

[0056] The feed oil F enters the hydrorefining reaction zone together with the hydrogen, contacts and reacts with the protective agent A and the hydrofinishing catalyst B, and the reaction effluent from the hydrofinishing reaction zone enters the hydrocracking reaction zone I without any intermediate separation. The first hydrocracking catalyst C contacts and reacts. After the reaction effluent of hydrocracking reaction zone I is mixed with middle distillate and hydrogen-rich gas, it enters hydrocracking reaction zone II, contacts and reacts with the second hydrocracking catalyst D, and breaks the alkyl side chain, and takes into account the Selective ring-opening cracking of tetrahydronaphthalene monocyclic aromatics. The reaction effluent from hydrocracking reaction zone II enters the separation facilities such as cold high-pressure separator, cold low-pressure separator, fractionation tower, etc. in turn, and obtains light gasoline fraction, heavy gasoline fraction, middle ...

Embodiment 3

[0060] The raw material oil G enters the hydrofinishing reaction zone together with the hydrogen, contacts and reacts with the protective agent A and the hydrofinishing catalyst B, and the reaction effluent from the hydrofinishing reaction zone enters the hydrocracking reaction zone I without any intermediate separation, and The first hydrocracking catalyst C contacts and reacts. After the reaction effluent of hydrocracking reaction zone I is mixed with middle distillate and hydrogen-rich gas, it enters hydrocracking reaction zone II, contacts and reacts with the second hydrocracking catalyst D, and breaks the alkyl side chain, and takes into account the Selective ring-opening cracking of tetrahydronaphthalene monocyclic aromatics. The reaction effluent from hydrocracking reaction zone II enters the separation facilities such as cold high-pressure separator, cold low-pressure separator, and fractionation tower in turn, and after cooling, separation, and fractionation, light ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com