Preparation method of xylene by alkylation of mixed crude benzene and methanol

A technology of xylene and alkylation, which is applied in the field of mixed crude benzene and methanol to produce xylene, can solve the problems of uneconomical, difficult practical application and industrialization, etc., achieve low cost, improve economic benefits and social Benefits, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

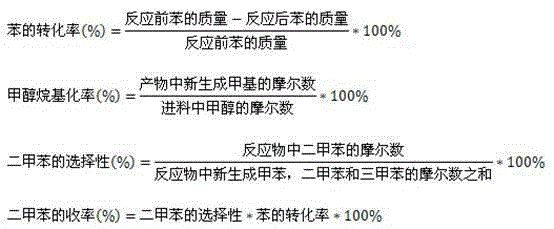

Embodiment 1

[0027] Embodiment 1: the two ends of the stainless steel fixed-bed reaction tube of inner diameter 1.5cm are loaded with appropriate amount of glass beads, and 5.0g granular 1.0%La are loaded in the middle 2 o 3 Modified acidic ZSM-5 catalyst (molecular sieve Si / Al=32, after the carrier gas is H 2 and 5h high-temperature passivation treatment at 550°C and pickling post-treatment with 0.5M oxalic acid aqueous solution for 1h at 80°C), then the carrier gas hydrogen, H 2 The molar ratio to hydrocarbons is 1:1; according to the molar ratio, the mixed crude benzene / methanol=1 / 1 is used to input the reaction raw materials with a pump; the mixed crude benzene raw material is specifically composed of 94% benzene, 5% toluene, and 1% xylene ; At a reaction temperature of 300°C, a reaction pressure of 0.1MPa, and a reaction space velocity of 0.5h -1 Under these conditions, the alkylation reaction produces xylene. The reaction product sample was analyzed by gas chromatography, and the ...

Embodiment 2

[0028]Embodiment 2: the two ends of the stainless steel fixed-bed reaction tube of internal diameter 1.5cm are loaded with appropriate amount of glass beads, and 4.0g granular 4.2%Ce are loaded in the middle 2 o 3 Modified acidic Beta catalyst (molecular sieve Si / Al=20, after the carrier gas is H 2 and 2h high temperature passivation treatment at 750°C and 3.0M oxalic acid aqueous solution pickling treatment at 60°C for 3h), and then pass the carrier gas hydrogen, H 2 The molar ratio to hydrocarbons is 5:1; according to the molar ratio, the mixed crude benzene / methanol=6 / 1 is used to input the reaction raw materials with a pump; the mixed crude benzene raw materials are specifically composed of 30% benzene, 60% toluene, 1% xylene, 1 % non-aromatics and 8% C9 aromatics; at a reaction temperature of 460°C, a reaction pressure of 5.0MPa, and a reaction space velocity of 4.0h -1 Under these conditions, the alkylation reaction produces xylene. The reaction product sample was ana...

Embodiment 3

[0029] Embodiment 3: the two ends of the stainless steel fixed-bed reaction tube of inner diameter 1.5cm are loaded with appropriate glass beads, and the acidic SAPO-11 catalyst (molecular sieve Si / Al=12 of molecular sieve Si / Al=12, H through the carrier gas 2 and 4h high-temperature passivation treatment at 650°C and pickling post-treatment with 1.5M oxalic acid aqueous solution for 2h at 70°C), and then the carrier gas carbon dioxide, CO 2 The molar ratio to hydrocarbons is 2:1; according to the molar ratio, the mixed crude benzene / methanol=3 / 1 is used to input the reaction raw materials with a pump; the mixed crude benzene raw materials are specifically composed of 40% benzene, 47% toluene, 2.4% xylene, 6 % non-aromatics and 4.6% C9 aromatics; at a reaction temperature of 380°C, a reaction pressure of 1.0MPa, and a reaction space velocity of 2.0h -1 Under these conditions, the alkylation reaction produces xylene. The reaction product sample was analyzed by gas chromatogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com