IML gloss oil and IML printing ink and preparation method and application thereof

A technology of ink and varnish, which is applied in the field of IML varnish and IML ink and its preparation, which can solve the problems of heavy ink odor, insufficient flexibility and temperature resistance of ink, and ink layer flushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) To prepare IML varnish, the mass percentage content of each component is as follows:

[0056] Tongde resin AK3010 70%

[0057] Durene 10%

[0058] Dimethyl Glutarate 20%.

[0059] The preparation method is as follows: the above components are mixed and stirred evenly.

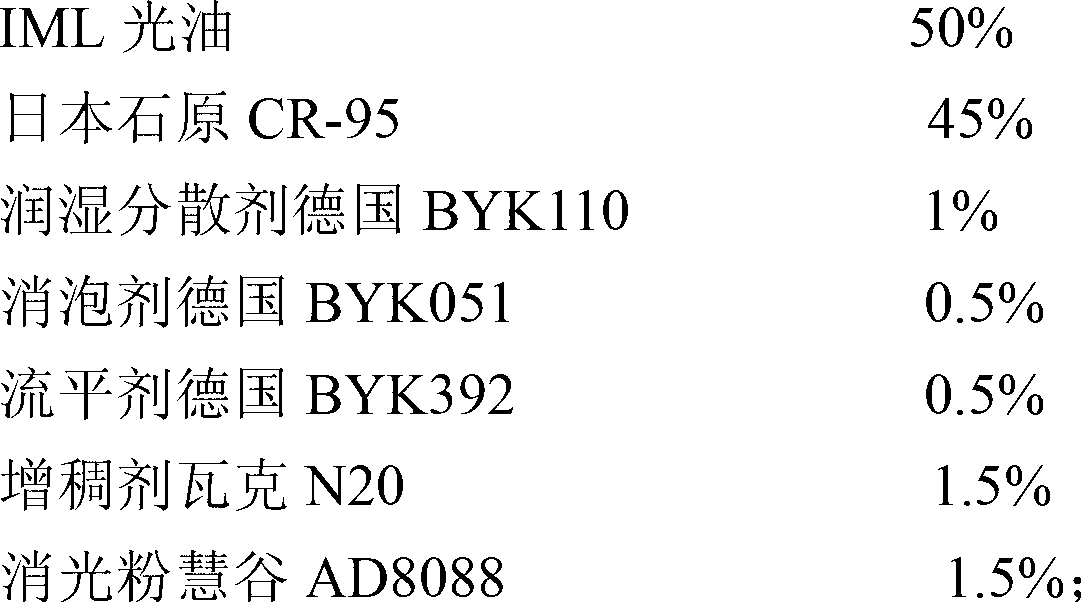

[0060] (2) Use the above-mentioned varnish to prepare component A in IML white ink, and the mass percentage content of each component is as follows:

[0061]

[0062] The preparation method of component A in IML white ink is as follows: mix IML varnish, BYK110, BYK051 and BYK392, stir with a high-speed disperser at high speed (1200r / min), then add CR-95 while stirring, after adding CR-95 After stirring for 5-10 minutes, add AD8088 and N20 in turn while stirring. After stirring for about 5 minutes, grind 3 times with a three-roll mill. When the fineness is less than 5 μm, it can be packed.

[0063] (3) Preparation of IML white ink: mix component A and Desmodur The mass ratio of N3300 is 10:1,...

Embodiment 2

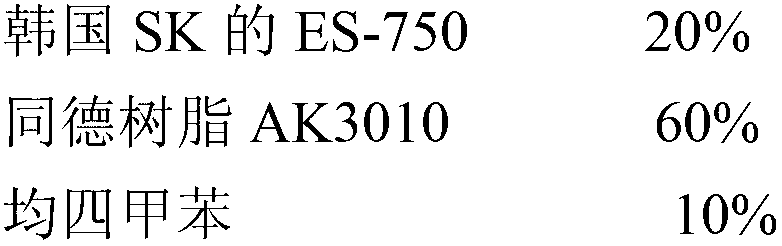

[0065] (1) To prepare IML varnish, the mass percentage content of each component is as follows:

[0066]

[0067]

[0068] The preparation method is as follows: the above components are mixed and stirred evenly.

[0069] (2) Use the above-mentioned varnish to prepare component A in IML white ink, and the mass percentage content of each component is as follows:

[0070]

[0071] The preparation method of component A in IML white ink is as follows: varnish, Mix Dispers610, BYK017 and Levelol495, stir with a high-speed disperser at high speed (1000r / min), then add CR-60-2 while stirring, add CR-60-2 and stir for 5 minutes, then add AD8088 and N20 in turn while stirring , after stirring for about 5 minutes, grind 3 times with a three-roll mill, and when the fineness is less than 5 μm, it can be packed.

[0072] (3) Preparation of IML white ink: mix component A and N75 is mixed according to the mass ratio of 10:1, add durene diluent equivalent to 15% of the total mass...

Embodiment 3

[0074] (1) To prepare IML varnish, the mass percentage content of each component is as follows:

[0075]

[0076] The preparation method is as follows: the above components are mixed and stirred evenly.

[0077] (2) Use the above-mentioned varnish to prepare component A in IML white ink, and the mass percentage content of each component is as follows:

[0078]

[0079]

[0080] The preparation method of component A in IML white ink is as follows: mix varnish, BYK161, BYK055 and Levelol839, stir with a high-speed disperser at high speed (1000r / min), then add CR-57 while stirring, add CR-57 and stir After 5 minutes, add AD8088 and N20 in turn while stirring. After stirring for about 5 minutes, grind 3 times with a three-roll mill. When the fineness is less than 5 μm, it can be packed.

[0081] (3) Preparation of IML white ink: mix component A and 4470 is proportioned according to the mass ratio of 10:2, adding the equivalent of component A and After the 4470 total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com