Environment-friendly FEVE (trifluorochloroethylene copolymer) fluorocarbon coating and preparation method thereof

A fluorocarbon coating, an environmentally friendly technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of endangering the health of workers, affecting the environment, and high cost, and achieves easy operation, excellent adhesion, The effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

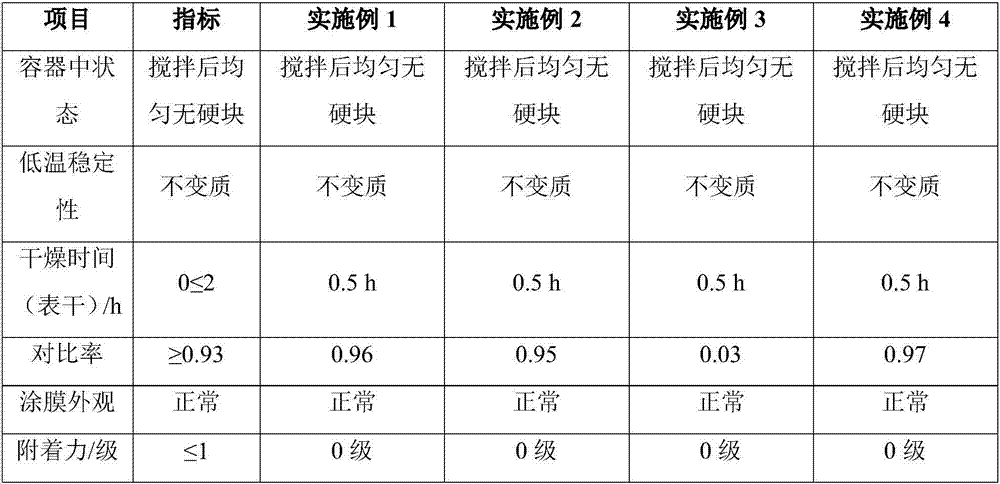

Embodiment 1

[0042] Step (1) Preparation of color paste

[0043] Weigh the raw materials for the preparation of color paste, deionized water 180g, AMP-95 multifunctional additive 1.62g, 250HBR cellulose thickener 1.62g, PE-100 wetting agent 2.16g, T-5040 dispersant 4.86g, NXZ Defoamer 0.54g, rutile titanium dioxide 253.8g, GA-4 mica powder 48.6g and nano wollastonite powder 48.6g.

[0044]Add 160g of deionized water to the kettle, start stirring at a speed of 300rpm, add AMP-95 multifunctional additive, and adjust the pH to 9-10; slowly add 250HBR cellulose thickener powder, and be careful not to stick to the stirring rod or material On the inner wall of the kettle, a colorless transparent viscous solution was obtained. Then, add PE-100 wetting agent, T-5040 dispersant, and NXZ defoamer to the solution in sequence. After the addition, increase the stirring speed to 500 rpm to obtain a light yellow turbid liquid.

[0045] Add titanium dioxide to the above obtained liquid at a stirring spe...

Embodiment 2

[0056] Step (1) Preparation of color paste

[0057] Weigh the raw materials for the preparation of the color paste, weigh the raw materials for the preparation of the color paste, deionized water 162g, AMP-95 multifunctional additive 1.47g, 250HBR cellulose thickener 1.47g, PE-100 wetting agent 1.96g, T -5040 dispersant 4.41g, NXZ defoamer 0.49g, rutile titanium dioxide 230.3g, GA-4 mica powder 44.1g and nano wollastonite powder 44.1g.

[0058] Add 145g of deionized water into the kettle, start stirring at 400rpm, add AMP-95 multifunctional additive, and adjust the pH to 9~10; slowly add 250HBR cellulose thickener powder, be careful not to stick to the stirring rod or material On the inner wall of the kettle, a colorless transparent viscous solution was obtained. Then, add PE-100 wetting agent, T-5040 dispersant, and NXZ defoamer to the solution in sequence. After the addition, increase the stirring speed to 700 rpm to obtain a light yellow turbid liquid.

[0059] Add titani...

Embodiment 3

[0070] Step (1) color paste preparation:

[0071] Weigh the raw materials for the preparation of the color paste, weigh the raw materials for the preparation of the color paste, deionized water 129g, AMP-95 multifunctional additive 1.17g, 250HBR cellulose thickener 1.17g, PE-100 wetting agent 1.56g, T -5040 dispersant 3.51g, NXZ defoamer 0.39g, rutile titanium dioxide 183.3g, GA-4 mica powder 35.1g and nano wollastonite powder 35.1g.

[0072] Add 115g of deionized water into the kettle, start stirring at 400rpm, add AMP-95 multifunctional additive, adjust the pH to 9~10; slowly add 250HBR cellulose thickener powder, be careful not to stick to the stirring rod or the material On the inner wall of the kettle, a colorless transparent viscous solution was obtained. Then, add PE-100 wetting agent, T-5040 dispersant, and NXZ defoamer to the solution in sequence. After the addition, increase the stirring speed to 600 rpm to obtain a light yellow turbid liquid.

[0073] Add titanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com