Long-branched-carbon-chain triazine ultraviolet absorbent compound and preparation method thereof

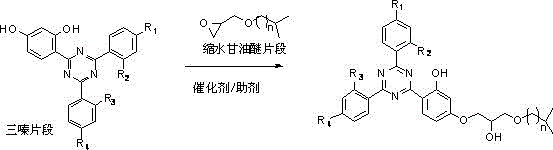

A technology of ultraviolet absorber and branched carbon chain, which is applied in the field of long branched carbon triazine ultraviolet absorber compound and its preparation, can solve the problems of immature production technology and process, poor performance, etc., and achieve high commercial application value, preparation The effect of simple operation and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be further described in detail below in conjunction with specific embodiments.

[0016] Implementation one

[0017] Nitrogen protection, add 550g xylene, 100g triazine fragment (2-[2,4-dihydroxyphenyl]-4,6-bis(2,4-dimethylphenyl)-1 , 3,5-triazine), 1g potassium iodide, 1g tetrabutylammonium bromide, 98g isomeric tridecyl glycidyl ether, heat up to 135 degrees, micro-reflux reaction for 12 to 15 hours, the detection of triazine fragment conversion rate is greater than 95%. After cooling to room temperature, the filtrate was washed once with water. The filtrate was concentrated, and the crude product was crystallized to obtain 145 g of the product, with a yield of 89%.

[0018] Implementation two.

[0019] Nitrogen protection, add 500g toluene, 83g triazine fragment (2-[2,4-dihydroxyphenyl]-4,6-bisphenyl-1,3,5-triazine) to 1 liter reaction flask, 0.6 g potassium iodide, 0.5 g tetrabutylammonium bromide, 100 g isomeric tridecy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com