Conversion method for low-grade heavy and residual oil

A residual oil and light technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve problems such as difficult to become asphalt products, unused asphalt, and increased bed pressure drop, so as to suppress coke formation, The effect of prolonging the start-up period and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

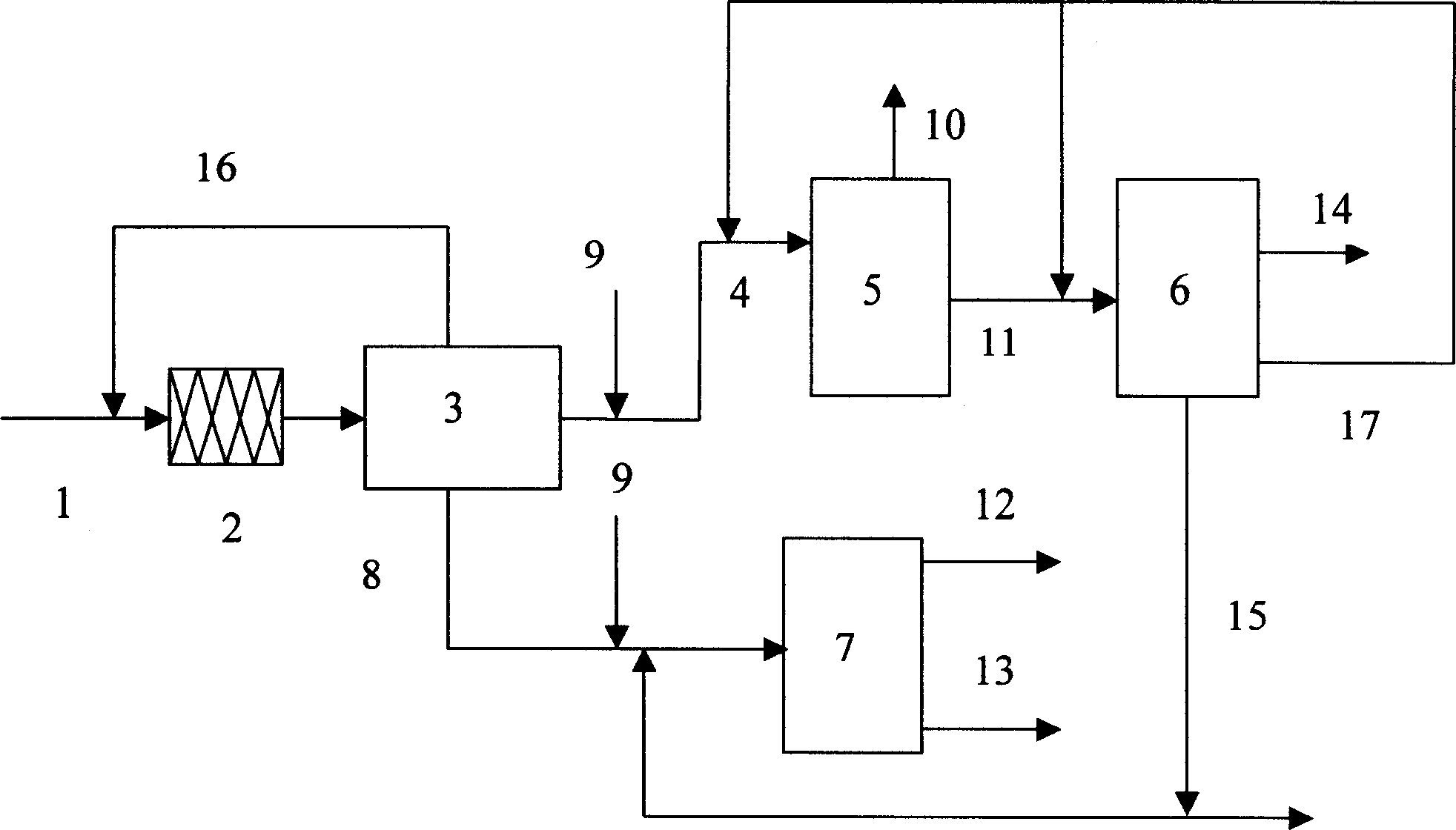

Image

Examples

Embodiment 1~2

[0039] This experiment investigates the changes in the properties of deasphalted oil obtained from two residual oil raw materials under different solvent extraction conditions. The data results show that the DAO yields of the two residual oil raw materials are 76wt% and 80wt%, respectively, the DAO n-heptane insolubles are 0, and the content of Ni and V is low, which is an excellent raw material for fixed-bed hydrotreating equipment. .

[0040] Item

Embodiment 3~4

[0042] This experiment illustrates the fixed bed hydrotreating of the DAO obtained in Examples 1 and 2.

[0043] The fixed-bed hydrogenation catalyst used in the test is the CEN and FZC series of hydrodemetalization catalysts produced by the pilot plant of Fushun Petrochemical Research Institute, and the ZTN and ZTS series of hydrodenitrogenation catalysts produced by the First Fertilizer Plant of Qilu Petrochemical Company. Hydrodesulfurization catalyst. The order of catalyst loading is hydrodemetalization, hydrodesulfurization, and hydrodenitrogenation catalyst. The hydrodemetalization catalysts used in this experiment are CEN-5 and CEN-6; the protective agents are CEN-2, CEN-4, FZC-16 (transition protective agent); the hydrodesulfurization catalysts ZTS-01, ZTS-02 , ZTS-03; Hydrodenitrogenation catalyst ZTN-01. The filling volume ratio between each catalyst is:

[0044] CEN-2: FZC-16: CEN-4: CEN-5: CEN-6: ZTS-01: ZTS-02: ZTS-03: ZTN-01=1: 1.25: 1.5: 2.62: 7.8: 6.63: 0.69: 0.87:...

Embodiment 5~6

[0049] This test illustrates the FCC test of the hydrogenated tail oil of Example 3 and Example 4 on a small riser catalytic cracking unit. The catalytic cracking test device has a processing capacity of 1kg / h and adopts a cyclic reaction-regeneration working mode. The catalytic cracking catalyst is CHV-1 catalyst produced by Changling Petroleum Refining and Chemical Total Stone Catalyst Plant.

[0050] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com