Catalytic cracking oil and gas separation method

A catalytic cracking and separation method technology, which is applied in the field of catalytic cracking oil-gas separation, can solve the problems of increasing gasoline octane number and low separation precision, and achieve the effects of reducing heat source temperature, improving separation efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The examples illustrate the gasoline separation effect of the catalytic cracking oil-gas separation method provided by the present invention.

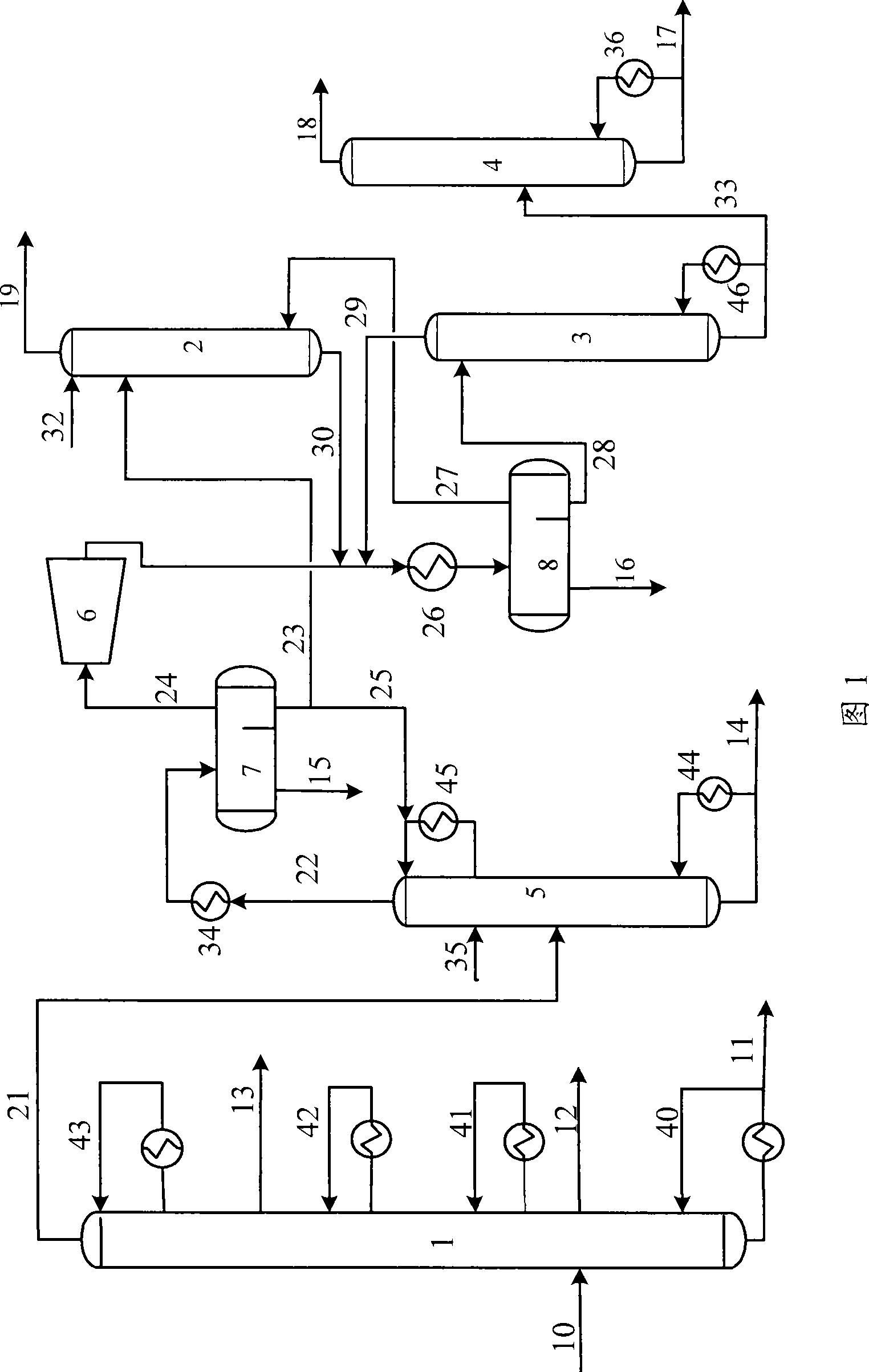

[0047] Separation of catalytic cracking reaction oil and gas according to the process shown in Figure 1, the oil and gas are introduced into the main fractionation tower, and the operation of the catalytic cracking main fractionation tower makes the top discharge be gasoline and fractions below C4, and the main fractionation tower is sequentially separated from top to bottom Diesel oil, heavy diesel oil and oil slurry; gasoline and fractions below C4 are introduced into the gasoline fractionation tower to separate heavy gasoline fractions, light gasoline and fractions below C4, and fractions below C4 are introduced into the subsequent absorption and stabilization system to separate light gasoline fractions and liquefy gas and dry gas.

[0048] The flow rate and composition of oil and gas in catalytic cracking reaction are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com