A combined method for processing inferior heavy oil

A combined method and low-quality heavy oil technology, which is applied in the fields of hydrotreating process, chemical instruments and methods, and hydrocarbon oil treatment, can solve the problems of high sulfur content in products, heavy regenerator load, low yield of light oil, etc., and achieve viscosity Low, reduce the regenerator load, reduce the effect of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

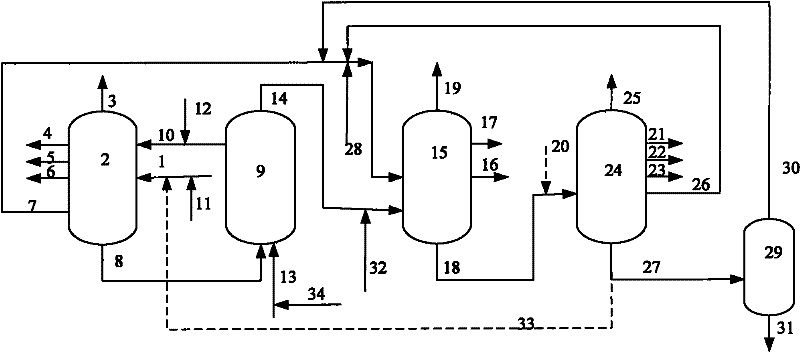

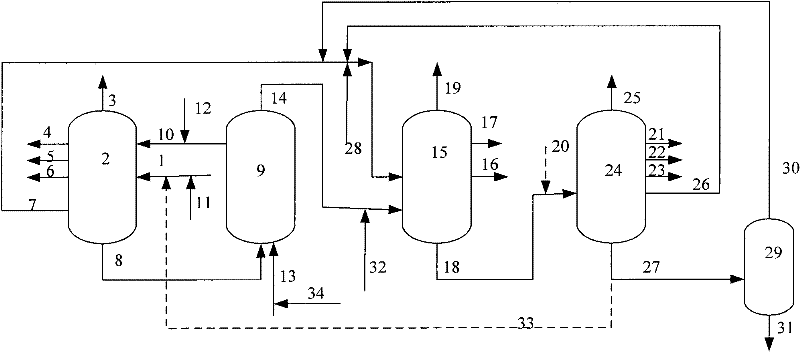

Method used

Image

Examples

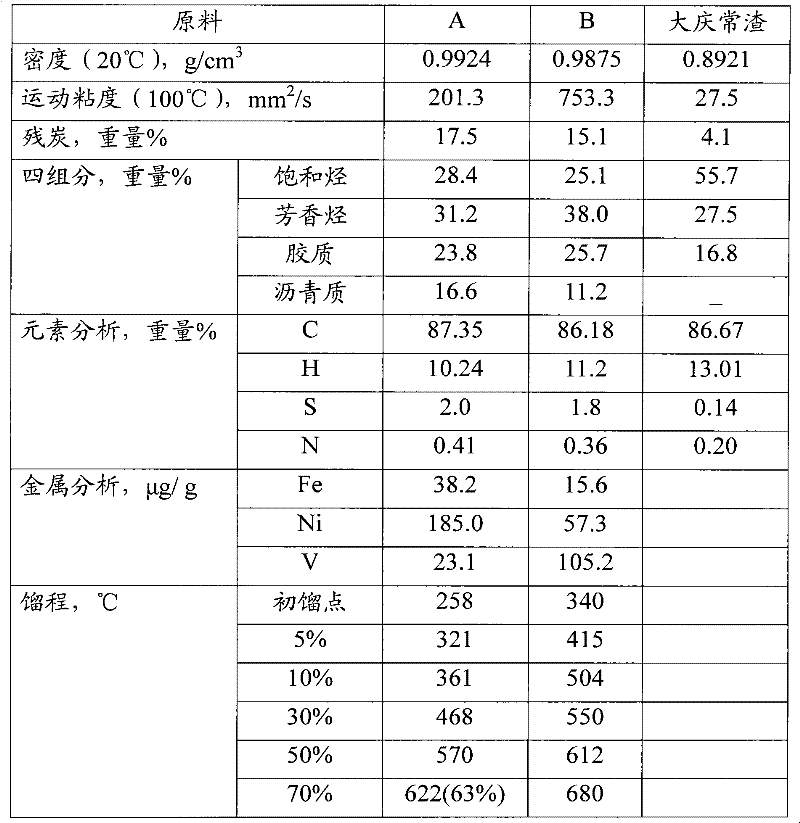

Embodiment 1

[0037] In the fixed fluidized bed reactor, the feedstock oil A (see Table 1 for its properties) enters the contact cracking unit and undergoes contact cracking with the contact agent. The contact cracking process conditions are: reaction temperature 510°C, catalyst-oil ratio 15.0, weight hourly space velocity: 5.0h -1 . The heavy oil fraction I obtained from the reaction enters the hydrotreating unit, and the carbon contact agent enters the gasification unit to undergo gasification reaction with the gasification agent. The reaction temperature of the gasification reactor is 750°C. The gasification product is prepared after the shift reaction. Hydrogen requires pure hydrogen. The distribution of contact cracking and gasification reaction products is shown in Table 2.

[0038] The mixture of heavy oil fraction I in the contact cracking unit and catalytically cracked recycle oil at a hydrogen partial pressure of 10MPa, a reaction temperature of 385°C, and a hydrogen-to-oil ratio of...

Embodiment 2

[0040] In the fixed fluidized bed reactor, the feedstock oil B (see Table 1 for its properties) enters the contact cracking unit and undergoes contact cracking with the contact agent. The contact cracking process conditions are: reaction temperature 560℃, agent-to-oil ratio 10.0, weight hourly space velocity: 20.0h -1 . The heavy oil fraction I obtained from the reaction enters the hydrotreating unit, and the carbon contact agent enters the gasification unit to undergo gasification reaction with the gasification agent. The reaction temperature of the gasification reactor is 850°C, and the gasification product is prepared after the shift reaction. Hydrogen requires pure hydrogen. The distribution of contact cracking and gasification reaction products is shown in Table 2.

[0041] The mixture of heavy oil fraction I of the contact cracking unit, FCC recycled oil, FCC slurry distillate and solvent refined oil, at a hydrogen partial pressure of 10MPa, a reaction temperature of 390°C...

Embodiment 3

[0043] In the fixed fluidized bed reactor, the feedstock oil B (see Table 1 for its properties) enters the contact cracking unit and undergoes contact cracking with the contact agent. The contact cracking process conditions are: reaction temperature 600°C, agent-oil ratio 5.0, weight hourly space velocity: 50.0h -1 . The heavy oil fraction I obtained from the reaction enters the hydrotreating unit, and enters the gasification unit with the carbon contact agent to undergo gasification reaction with the gasification agent. The reaction temperature of the gasification reactor is 900°C. The gasification product is prepared after the shift reaction. Hydrogen requires pure hydrogen. The distribution of contact cracking and gasification reaction products is shown in Table 2.

[0044] The mixture of heavy oil fraction I of the contact cracking unit, FCC recycled oil and vacuum gas oil, at a hydrogen partial pressure of 12MPa, a reaction temperature of 385°C, and a hydrogen-oil ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com